Modified PTA (pure terephthalic acid), modified polyester and flame-retardant and anti-aging polyester fiber prepared from modified polyester

A technology of modified polyester and anti-aging agent, used in the manufacture of fire-retardant and flame-retardant filaments, single-component polyester rayon, etc., can solve the problem of single PTA products, no consideration, no refinement products and special product research Development and other issues to achieve good functional effects, improve dispersion and compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

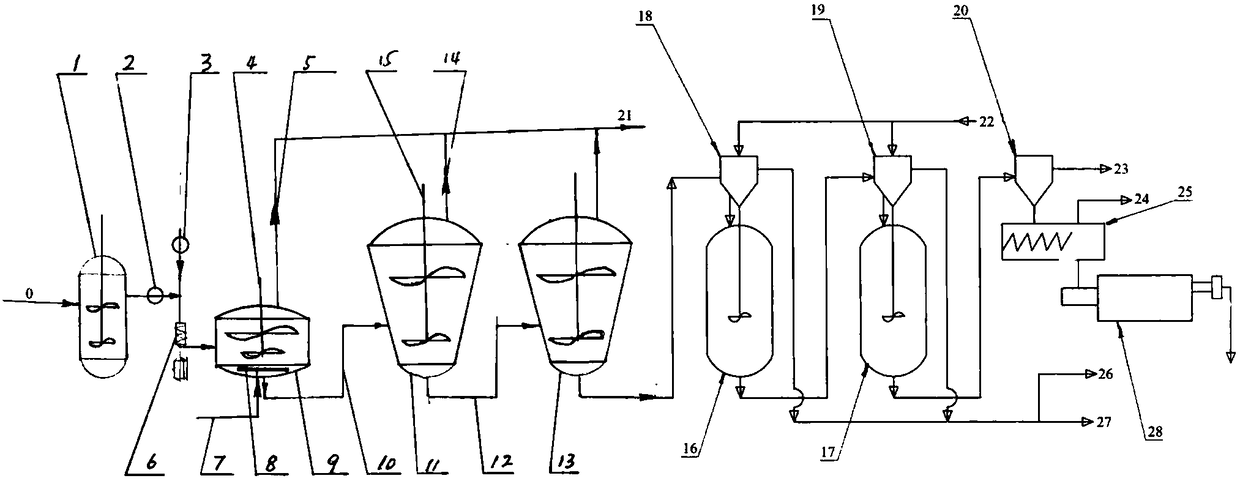

Image

Examples

Embodiment 1

[0054] The preparation method of modified PTA described in the present embodiment comprises the steps:

[0055] (1) Get 15kg of nano-scale hectorite powder, 15kg of nano-scale illite powder, 10kg of nano-scale silicon dioxide powder, and 300kg of dehydrated alcohol solution of laurylamine polyoxyethylene ether with a mass concentration of 15wt%, mix and stir for 0.5h , disperse by ultrasonic waves for 3 hours, and carry out vacuum spray drying at 100°C after centrifugal dehydration to obtain the required flame retardant and antiaging agent;

[0056] (2) get mass concentration and be that the oxalic acid aqueous solution 60kg of 10wt%, mass concentration are the flame retardant anti-aging agent 6kg that step (1) obtains 6kg, bismuth vanadate 5kg, nanoscale conductive mica powder 2kg that are the hypochlorous acid aqueous solution 24kg of 2wt%. , nano-scale illite powder 6kg, mixed with a high-energy ball mill at a liquid phase of 50 ° C for 6 hours, then moved to a titanium-lin...

Embodiment 2

[0060] The preparation method of modified PTA described in the present embodiment comprises the steps:

[0061] (1) Get 20kg of nanoscale hectorite powder, 8kg of nanoscale illite powder, 15kg of nanoscale silicon dioxide powder, and 150kg of dehydrated alcohol solution of laurylamine polyoxyethylene ether with a mass concentration of 30wt%, mix and stir for 1.5h , disperse by ultrasonic waves for 1.5h, and carry out vacuum spray drying at 150°C after centrifugal dehydration to obtain the required flame retardant and antiaging agent;

[0062] (2) get mass concentration and be that the oxalic acid aqueous solution 80kg of 6wt%, mass concentration are the flame retardant anti-aging agent 12kg that step (1) obtains 12kg, bismuth vanadate 2kg, nanoscale conductive mica powder 3kg that are the hypochlorous acid aqueous solution 12kg of 4wt%. , nano-scale illite powder 4kg, mixed with a high-energy ball mill at a liquid phase of 65°C for 3 hours, then moved to a titanium-lined hydro...

Embodiment 3

[0066] The preparation method of modified PTA described in the present embodiment comprises the steps:

[0067] (1) get nanoscale hectorite powder 18kg, nanoscale illite powder 12kg, nanoscale silicon dioxide powder body 12kg, and mass concentration be 225kg of dehydrated alcohol solution of laurylamine polyoxyethylene ether of 22wt%, mix and stir 1h, Disperse with ultrasonic waves for 2.5 hours, and then carry out vacuum spray drying at 125°C after centrifugal dehydration to obtain the required modified additives;

[0068] (2) get mass concentration and be that the oxalic acid aqueous solution 70kg of 8wt%, mass concentration are the flame retardant anti-aging agent 9kg that step (1) obtains 9kg, bismuth vanadate 3.5kg, nanoscale conductive mica powder that are the hypochlorous acid aqueous solution 18kg of 3wt% Mix 2.5kg and 5kg of nano-scale illite powder, grind for 5 hours in the liquid phase at 58°C with a high-energy ball mill, then move to a titanium-lined hydrothermal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com