High-tenacity composite regenerated plastic and preparation method thereof

A composite regeneration, high toughness technology, applied in the field of composite materials, can solve the problems of no toughness, low strength, poor thermal stability, etc., to improve compatibility and dispersion, reduce production and use costs, and improve strength and toughness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

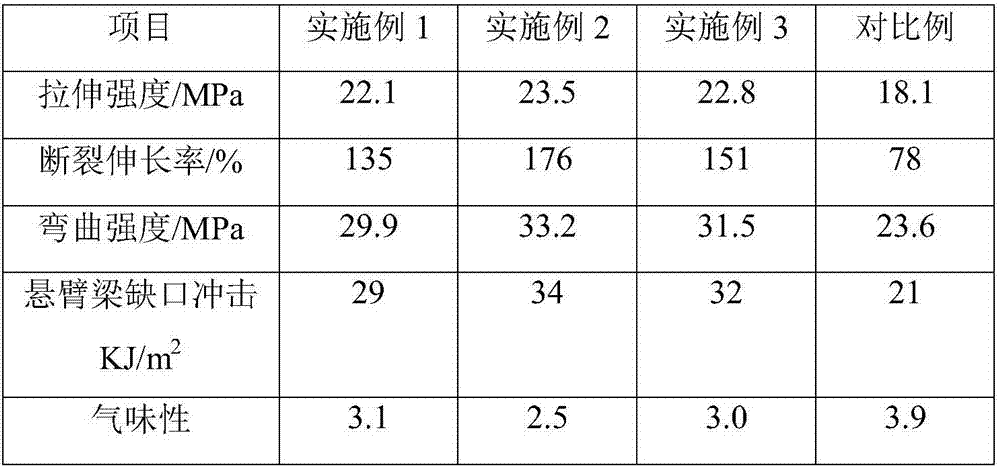

Examples

Embodiment 1

[0027] A high-toughness composite recycled plastic is prepared from the following raw materials in parts by weight: 100 parts of waste plastics, 10 parts of calcium borate, 50 parts of filler, 0.5 parts of antioxidant, 10 parts of toughening agent, N, N' - 3 parts of methylenebisacrylamide, 10 parts of strengthening agent.

[0028] As mentioned above, the filler is prepared by coupling wood powder and blast furnace slag fine powder according to the weight ratio of 1:0.5.

[0029] Said coupling wood flour is prepared by mixing 50-200 mesh rice bran powder at 110°C at 900 rpm, adding silane coupling agent KH560 accounting for 2% of the weight of rice bran powder while stirring, and stirring at high speed for 20 minutes of.

[0030] As stated, the particle size of blast furnace slag powder is 0.075-0.1mm, and the main active ingredient and content are CaO 3 More than 3.64wt%, SiO 2 More than 32.93wt%, Al 2 o 3 14.72wt% or more.

[0031] As mentioned, the toughening agent ...

Embodiment 2

[0040] A high-toughness composite recycled plastic is prepared from the following raw materials in parts by weight: 100 parts of waste plastic, 13 parts of calcium borate, 40 parts of filler, 1 part of antioxidant, 20 parts of toughening agent, N, N' - 5 parts of methylenebisacrylamide, 8 parts of strengthening agent.

[0041] As mentioned above, the filler is prepared by coupling wood flour and blast furnace slag fine powder according to the weight ratio of 1:0.8.

[0042] As mentioned, the toughening agent is made of polyvinyl alcohol, styrene-butadiene-styrene block copolymer and polychlorotrifluoroethylene in a weight ratio of 1:2.5:0.8.

[0043] As mentioned above, the strengthening agent is made of tungsten carbide powder and ethylenediaminetetraacetic acid in a weight ratio of 1:1.5.

[0044] Said waste plastics are polypropylene (PP) which is sorted and granulated, and the waste plastics are 60-80 mesh particles.

[0045] All the other are with embodiment 1.

Embodiment 3

[0047] A high-toughness composite recycled plastic, which is prepared from the following raw materials in parts by weight: 100 parts of waste plastic, 16 parts of calcium borate, 30 parts of filler, 1.5 parts of antioxidant, 30 parts of toughening agent, N, N' - 6 parts of methylenebisacrylamide, 6 parts of strengthening agent.

[0048] As mentioned above, the filler is prepared by coupling wood powder and blast furnace slag fine powder according to the weight ratio of 1:1.

[0049] As mentioned, the toughening agent is made of polyvinyl alcohol, styrene-butadiene-styrene block copolymer and polychlorotrifluoroethylene in a weight ratio of 1:2:1.

[0050] As mentioned above, the reinforcing agent is made of tungsten carbide powder and ethylenediaminetetraacetic acid in a weight ratio of 1:2.

[0051] Said waste plastics are high-density polyethylene (HDPE) granulated by sorting, and the waste plastics are 60-80 mesh particles.

[0052] All the other are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com