Descaling system for vapor generator in ironing and cleaning equipment

A technology for steam generators and cleaning equipment, which is applied in the field of ironing and cleaning equipment, and can solve problems such as difficult removal of dirt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

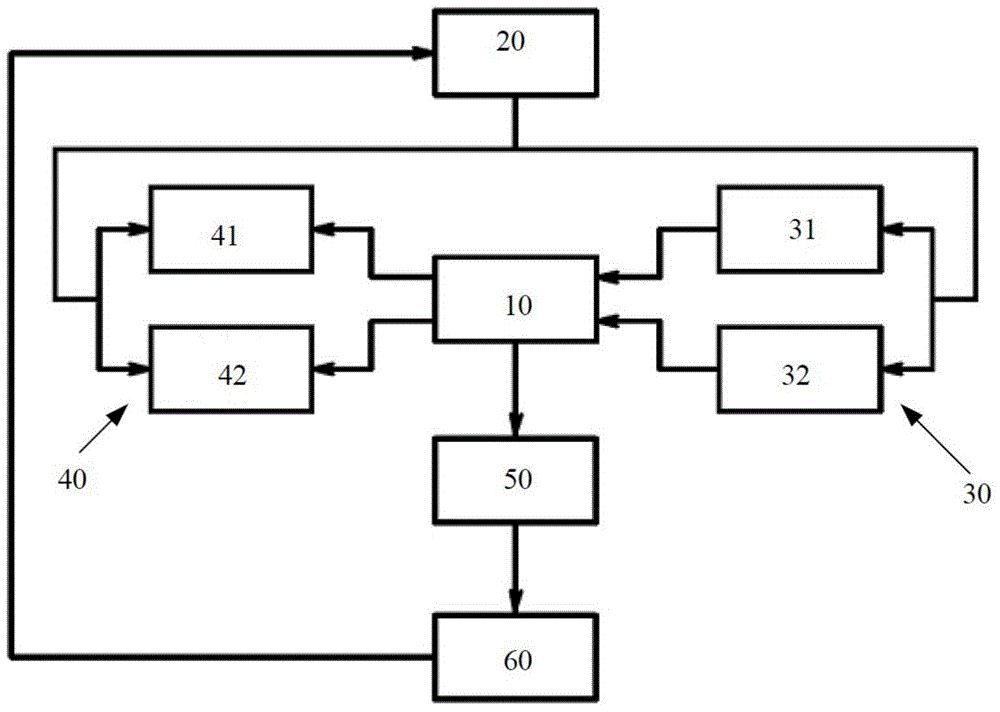

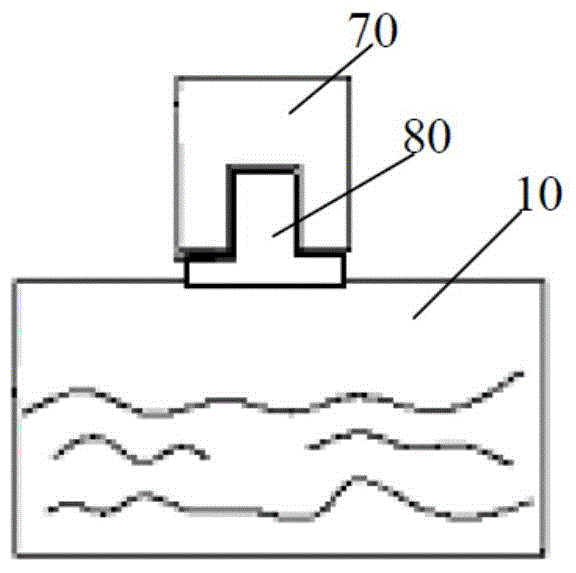

[0037] figure 1 It is a block diagram of the descaling system of the invention for steam generators in ironing and cleaning appliances. like figure 1 As shown, the present invention discloses a descaling system for a steam generator in ironing and cleaning equipment, and the descaling system is connected with the steam generator 10 to form a circulation loop. Wherein, the descaling system includes a control unit 20 , a descaling device 30 , a detection device 40 and a sewage discharge unit 50 . Preferably, the descaling system further includes a water collection box 60 . The control unit 20, the detection device 40, the steam generator 10 and the descaling device 30 are connected in series in sequence to form a circulation loop.

[0038] The control unit 20 is used to control the automatic or manual operation of the descaling system, such as starting descaling, controlling the water level and temperature in the steam generator 10, controlling the startup and running time of...

Embodiment 2

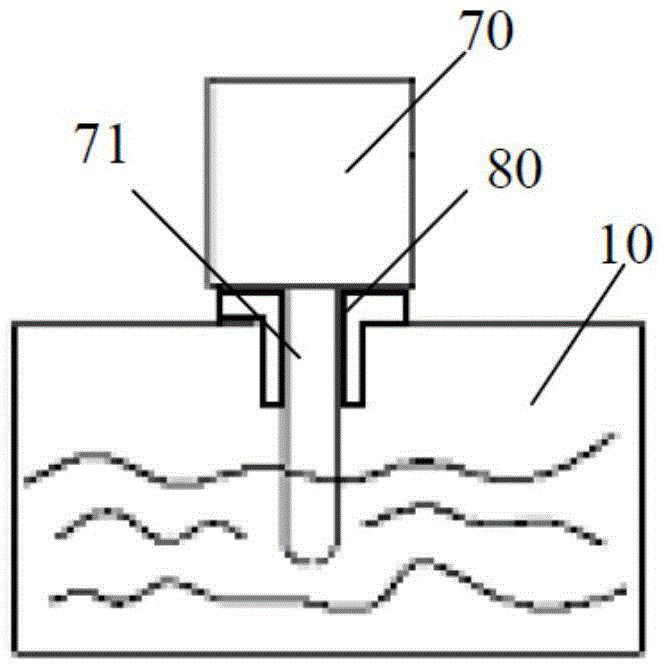

[0046] image 3 Schematic diagram of the installation of the ultrasonic vibrator in the descaling system of the steam generator in ironing and cleaning equipment according to the present invention Figure II . Such as image 3 As shown, the structure of this embodiment is basically the same as that of Embodiment 1, the difference is that: the ultrasonic vibrator 70 is fixed on the steam generator 10 through the fixer 80, and the vibrating end 71 of the ultrasonic vibrator 70 extends to the steam generator. device 10. This further effectively breaks up the dirt. Finally, after the ultrasonic vibration unit tooling is completed, the sewage in the steam generator 10 is discharged by starting the electromagnetic valve in the sewage discharge unit 50, and then the water supply unit 31 supplies water to the steam generator 10 again, thereby completing a coherent dewatering process. Sewage cycle.

[0047] According to the above description of the structure of the descaling syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com