Judgment method for crucial moments in full process of cutting working procedure of numerical control machine tool

A critical moment and whole-process technology, applied in the field of CNC machine tools, can solve problems affecting the normal operation of machine tools, low judgment accuracy, inconvenient installation, etc., achieve accurate statistics of machine tool effective running time and effective utilization rate of machine tools, and facilitate online acquisition, Simple and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

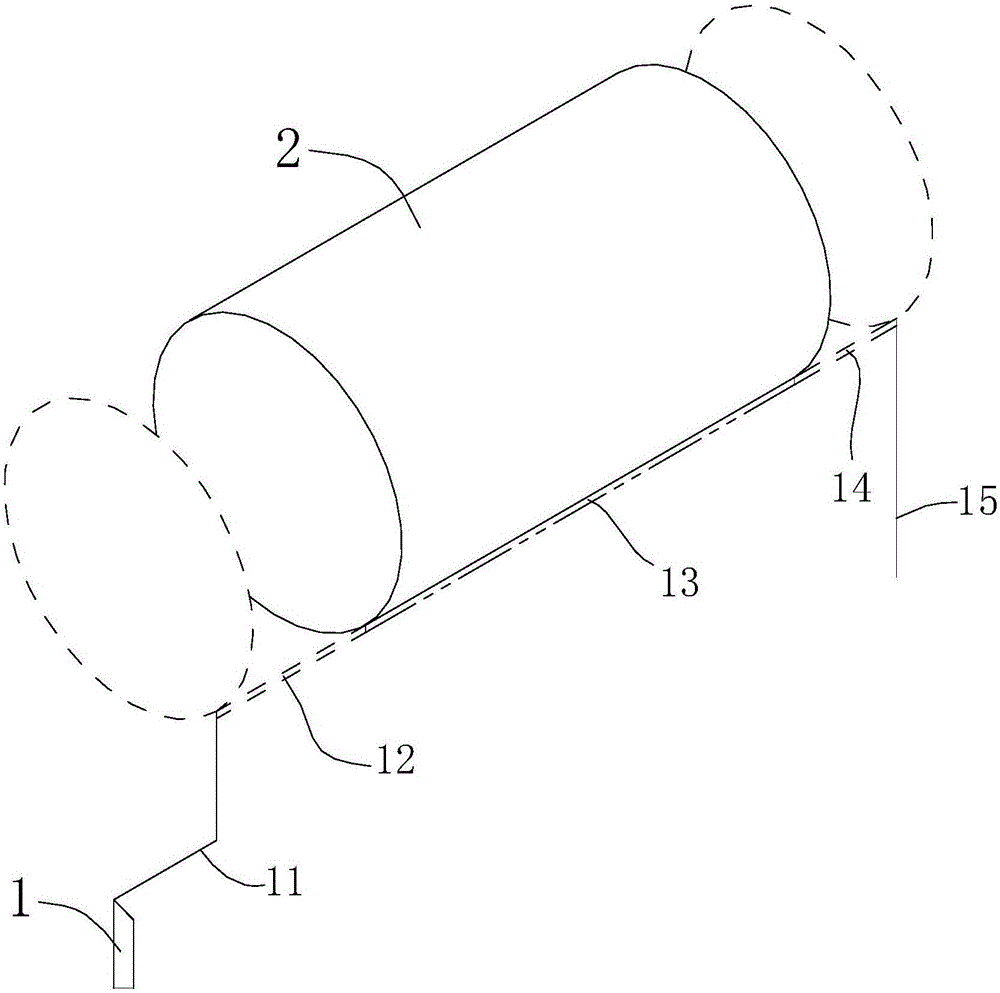

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings.

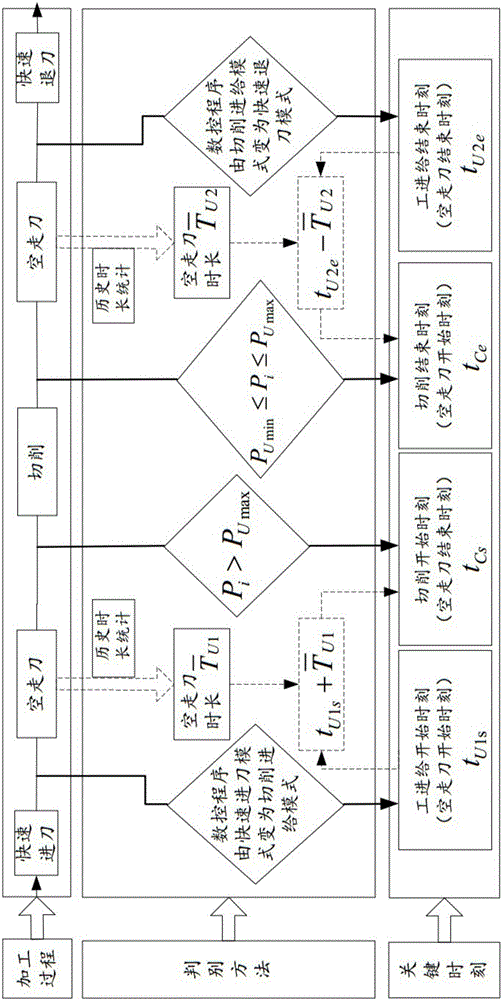

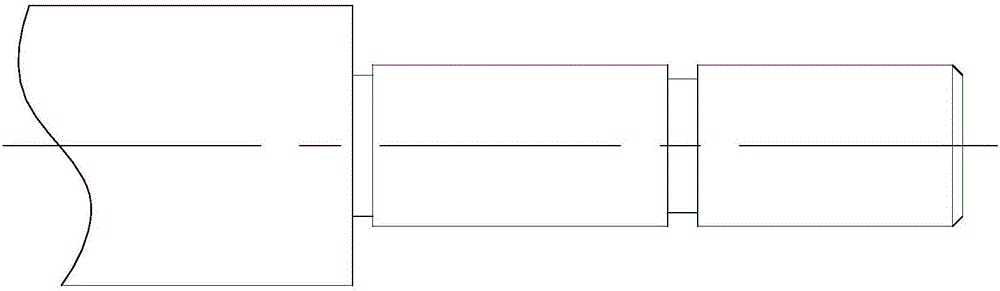

[0028]Specific implementation: during machine tool processing, the tool path of a complete working step is: machine tool reference point->safety plane->workpiece cutting->safety plane->machine tool reference point, where the safety plane refers to the machine tool to prevent rapid movement The plane established in the space close to the surface of the workpiece when the tool collides with the surface of the workpiece, and between the plane and the surface of the workpiece, the speed of the tool is the cutting feed rate. In this cutting process, the process of the tool approaching the workpiece surface from the safety plane at the feed speed (or returning to the safety plane from the workpiece surface after cutting) is called empty cutting. Usually, a complete cutting step includes two idling tool passes: the first idling cutter is the process that the tool le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com