Moving contact structure of high-voltage direct current sealing contactor

A sealed contact, high-voltage DC technology, applied in relays, electromagnetic relays, electromagnetic relay details, etc., can solve the problems of long arcing time of the main contact, large contact wear, and difficulty in disconnection, achieving small size and reducing combustion. Arc time, loss reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

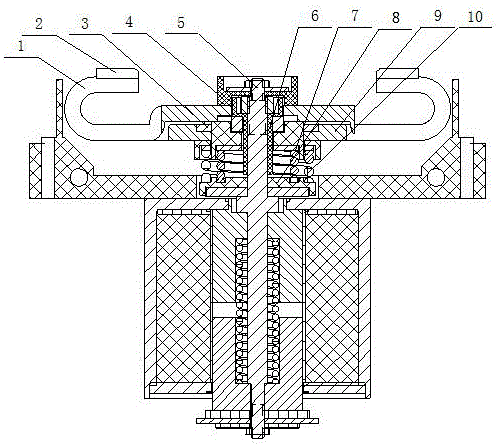

[0015] Below in conjunction with accompanying drawing, the present invention is described in further detail:

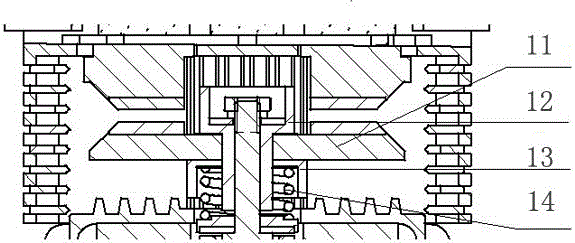

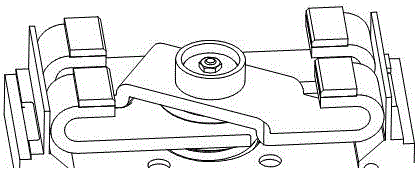

[0016] Such as image 3 As shown, the structure of the moving contact of the high-voltage DC sealed contactor mainly includes the first moving contact piece 1, the moving contact 2, the first upper bushing 4, the electromagnetic drive system 5, the second upper bushing 6, the first contact The spring 7 and the supporting washer 8 are sequentially connected by riveting, fasteners and corresponding fixing holes; The moving contact piece 9, a support adjustment washer 3 arranged on the second moving contact piece 9 and a second contact spring 1 arranged outside the first contact spring 7; the first moving contact piece 1 and the second The moving contact piece 9 is in the shape of a "J".

[0017] The first moving contact piece 1 and the second moving contact piece 9 form an assembly by supporting the adjusting washer 3 and have the same movement state and respective ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com