Method and device for tempering preforms

一种预制坯件、设备的技术,应用在用于对预制坯件进行调温和设备领域,能够解决降低加热器件效率、热量损失加热功率大等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

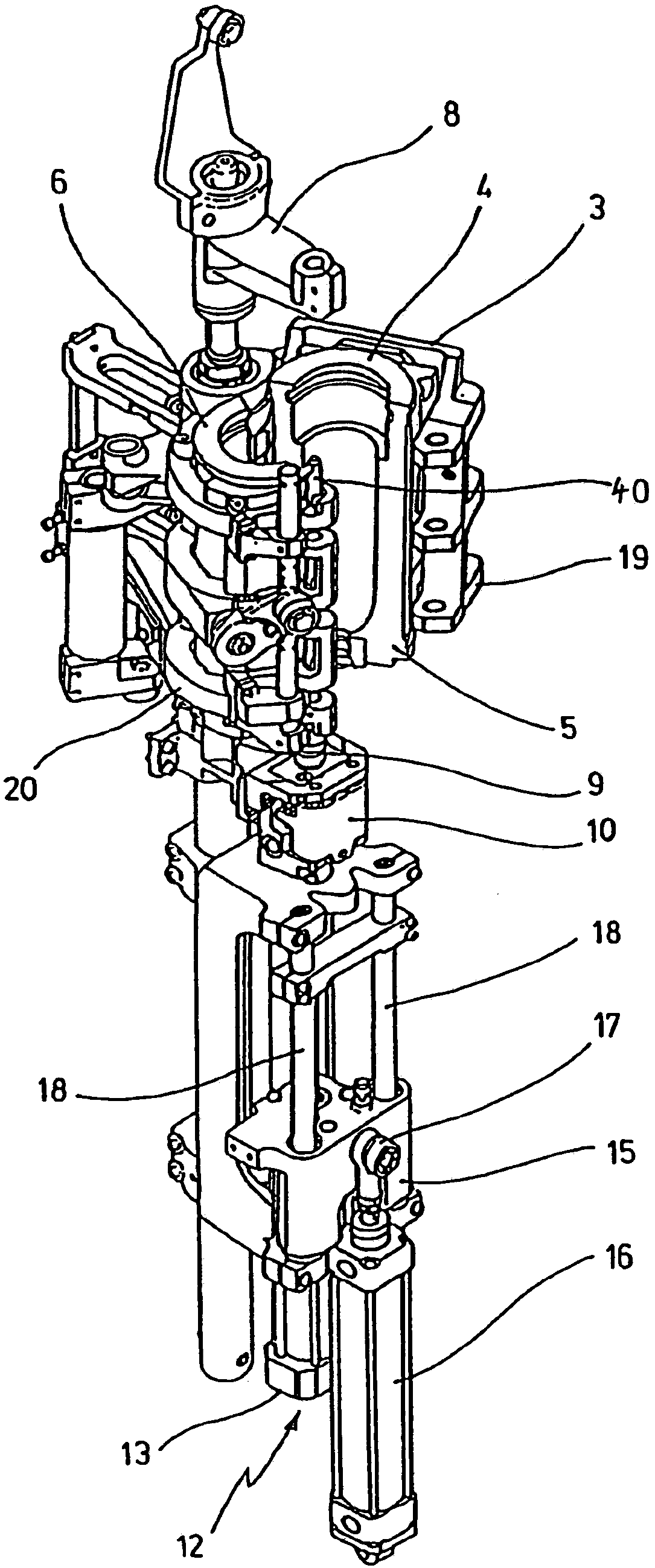

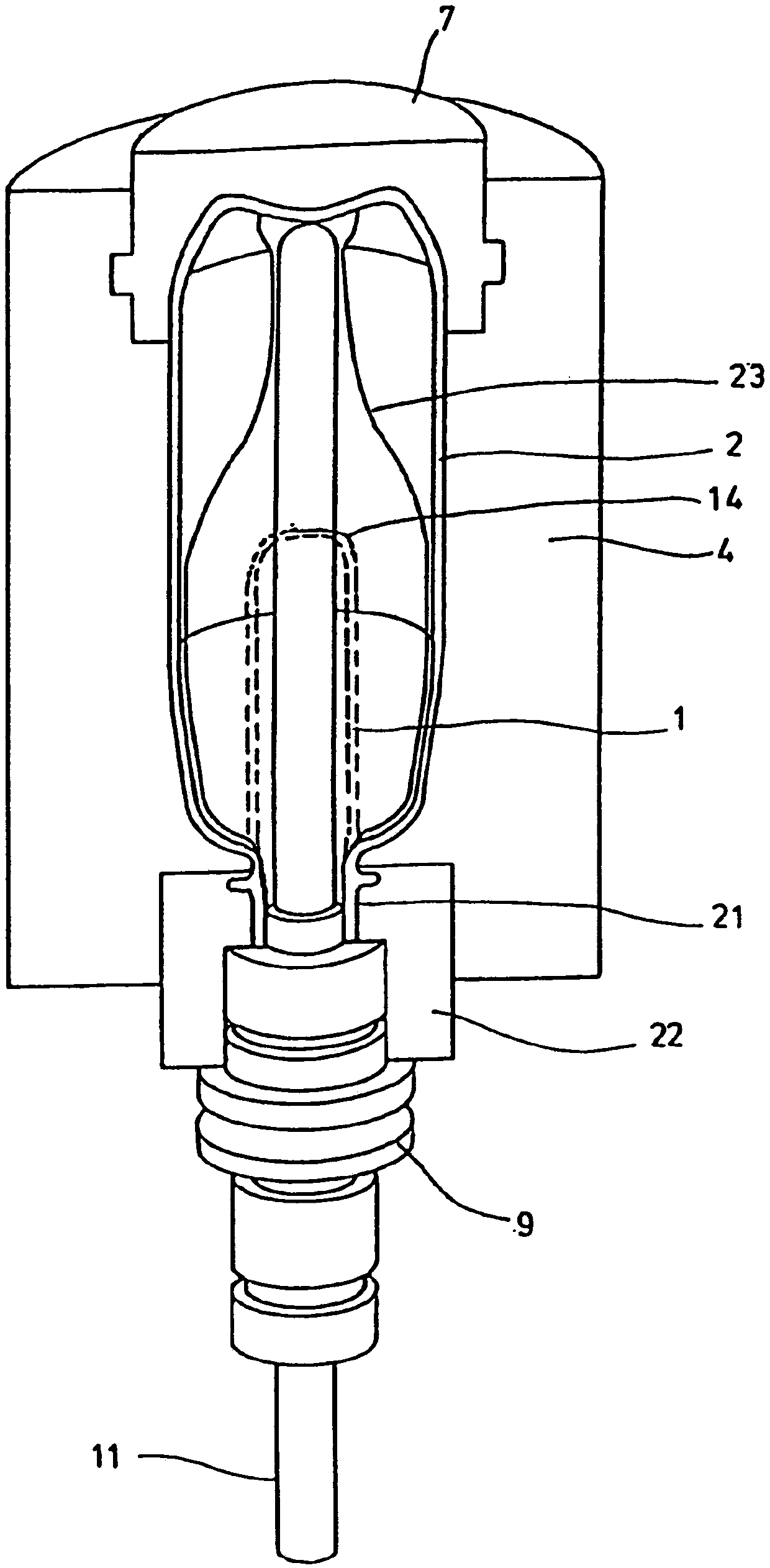

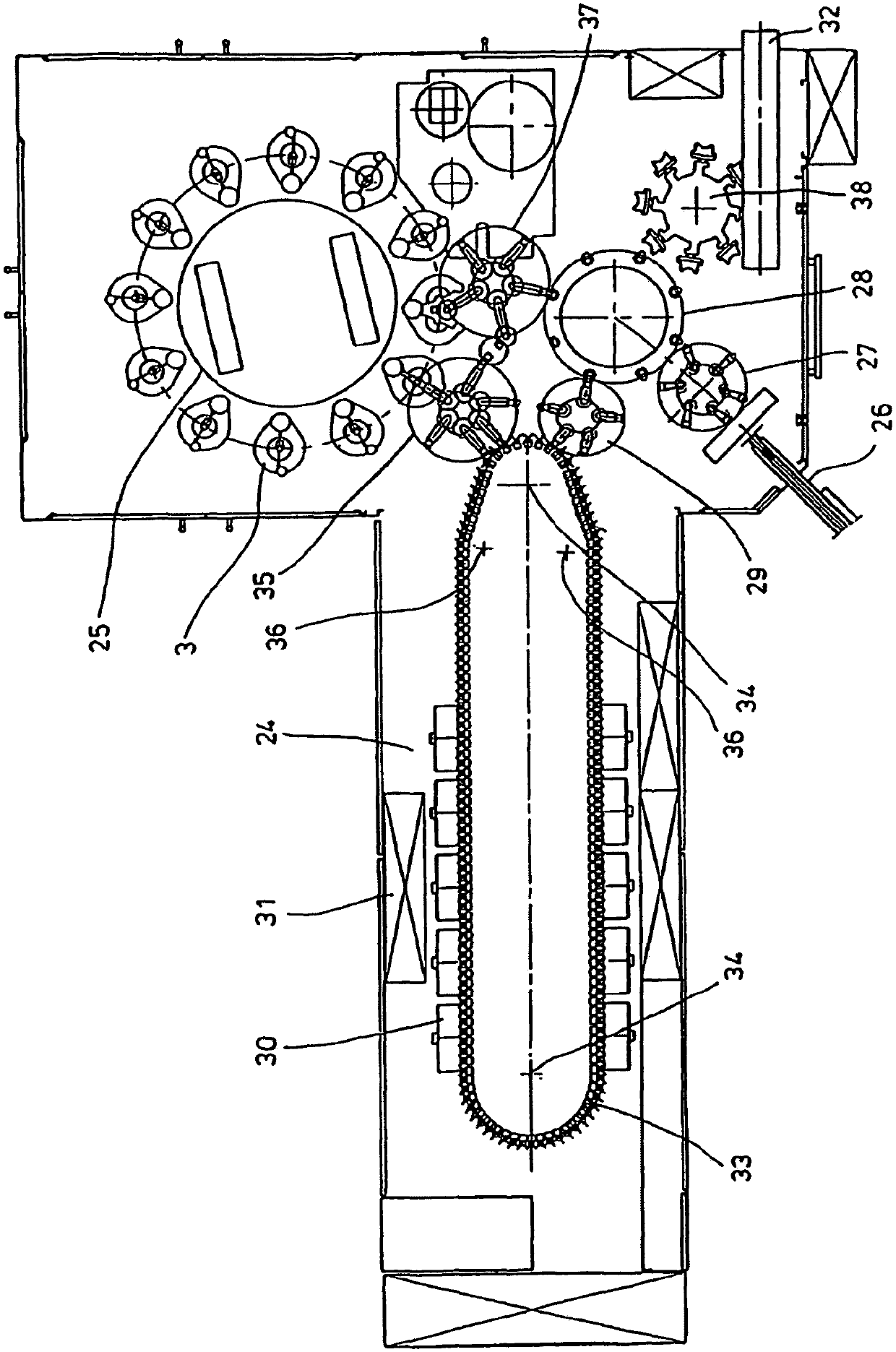

[0033] exist figure 1 in and in figure 2 The basic structure of a device for forming preforms 1 into containers 2 is shown in .

[0034] The plant for shaping the containers 2 essentially consists of a blow molding station 3 which is provided with blow molds 4 into which the preforms 1 can be inserted. The preform 1 can, without limiting the versatility, be an injection molded part made of polyethylene terephthalate (PET). However, other suitable thermoplastic materials are also known, from which the preforms can be formed. In order to allow the preform 1 to be inserted into the blow mold 4 and to enable the finished container 2 to be removed, the blow mold 4 consists of mold halves 5, 6 and a bottom part 7 which can be lifted by means of a lifting device. 8 positioning. The preforms 1 can be held in the region of the blow molding station 3 by a transport mandrel 9 which, together with the preforms 1 , passes through several processing stations within the installation. H...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com