Spring damper strut bearing with cover of two-component parts

A technology of shock absorbing struts and bearings, applied in the direction of ball bearings, shafts and bearings, vehicle components, etc., which can solve problems such as damage and profile intrusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

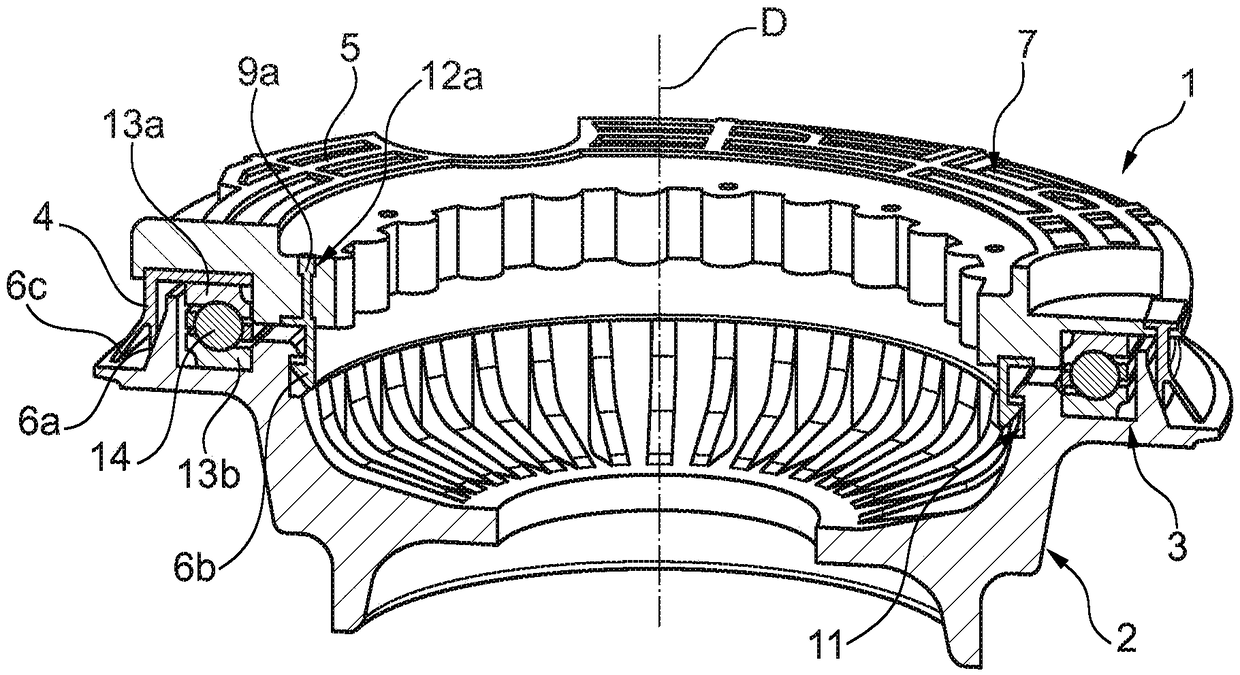

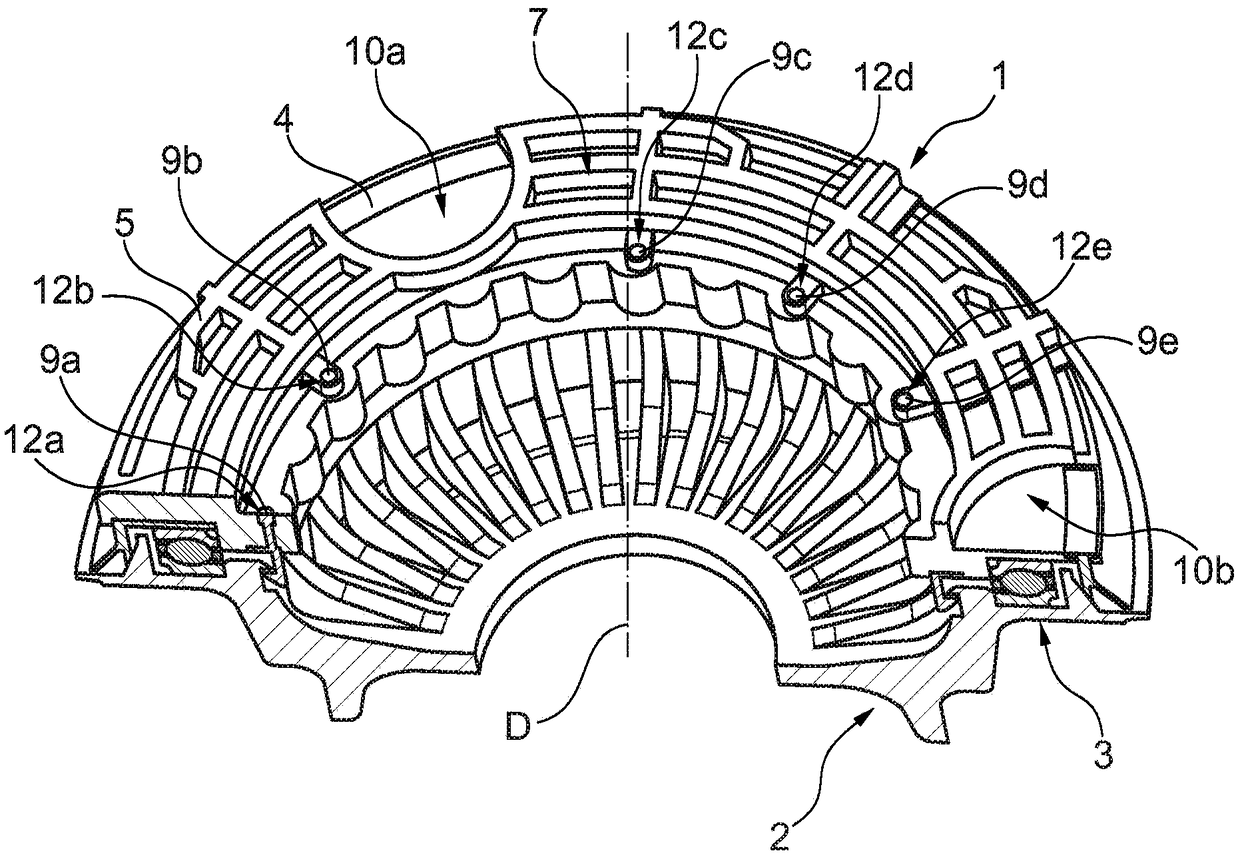

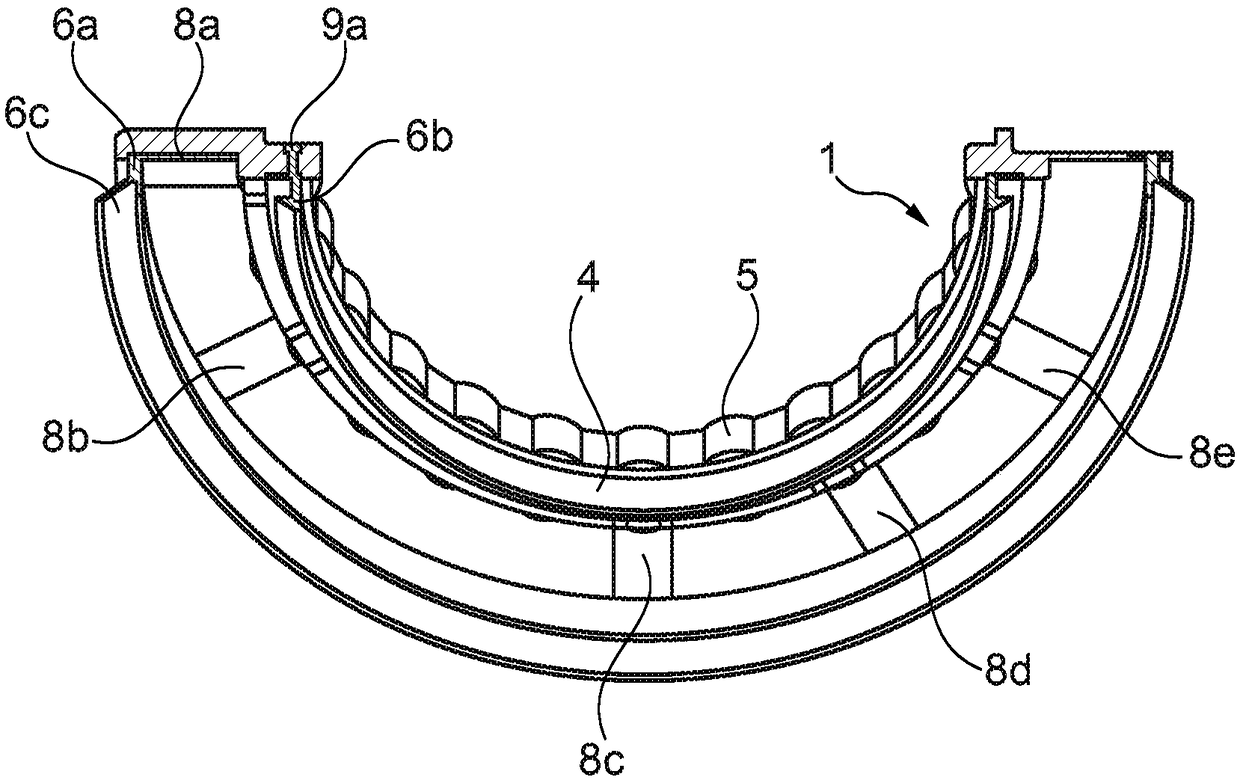

[0019] according to figure 1 and 2 The illustration in FIG. 1 shows a spring strut bearing according to the invention. It has a cover 1 and a guide ring 2 made of glass-fiber-reinforced plastic. The guide ring is mounted rotatably about an axis of rotation D relative to the cover 1 . The cover 1 is arranged on an arch bearing (not shown here) of the motor vehicle chassis. In this case, the end faces bear against the arch bearing. The guide ring 2 accommodates the axial ends of the shock absorber springs (not shown here). The spring force of the shock absorber spring is transmitted via the guide ring 2 into the cover 1 and from there into the arch bearing.

[0020] The guide ring 2 is supported axially in the direction of the axis of rotation D on the cover 1 via a thrust bearing 3 . The thrust bearing 3 is used to transmit the forces acting along the axis of rotation D from the guide ring 2 to the cover 1 . Thrust bearing 3 here has a plurality of rolling bodies 14 moun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com