Bidirectional bearing, drive train, planetary gear and wind generator

A planetary gear and bearing technology, applied in the field of wind power generators, to achieve the effect of compact design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] figure 1 is a simplified wind generator 2 according to an embodiment of the invention. The wind turbine 2 comprises a support structure 4 resting on a suitable foundation in the sea 6 . Merely by way of example, the wind generator 2 is an offshore wind generator. A nacelle (not visible) is arranged at the top of a support structure 4 which may be eg a tower. A rotor hub 8 carrying a plurality of rotor blades 10 is coupled to a main shaft 72 of a drive train 70 .

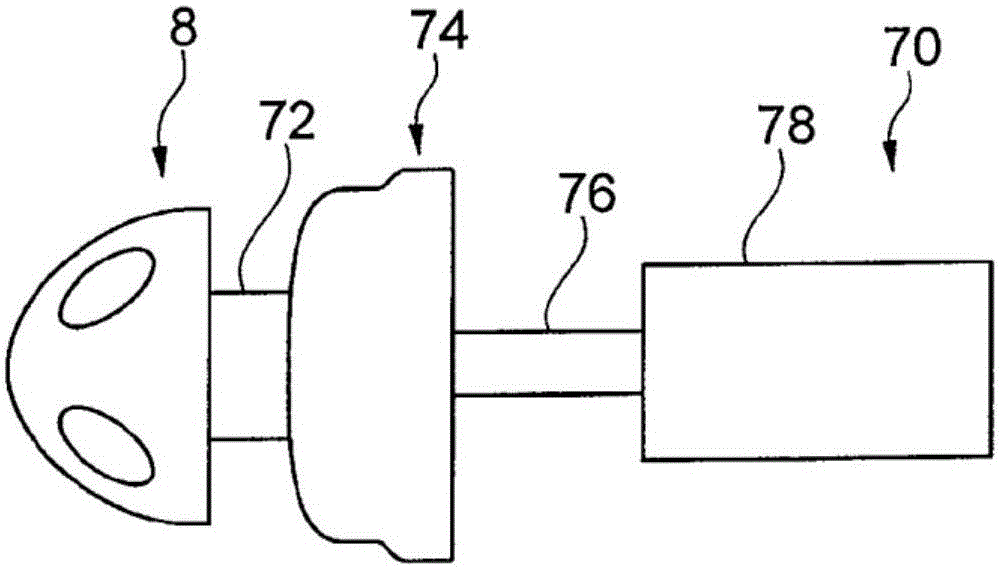

[0025] figure 2 A simplified drive train 70 is shown according to an embodiment of the invention. The drive train 70 may be arranged in the nacelle of the wind turbine 2 . The rotor hub 8 is coupled to a main shaft 72 which is the drive shaft for planetary gears 74 . The driven shaft of planetary gear 74 drives an input shaft 76 of generator 78 . Drive train 70 may include rotor hub 8 , main shaft 72 , planetary gears 74 and its output shaft, which is an input shaft 76 of generator 78 .

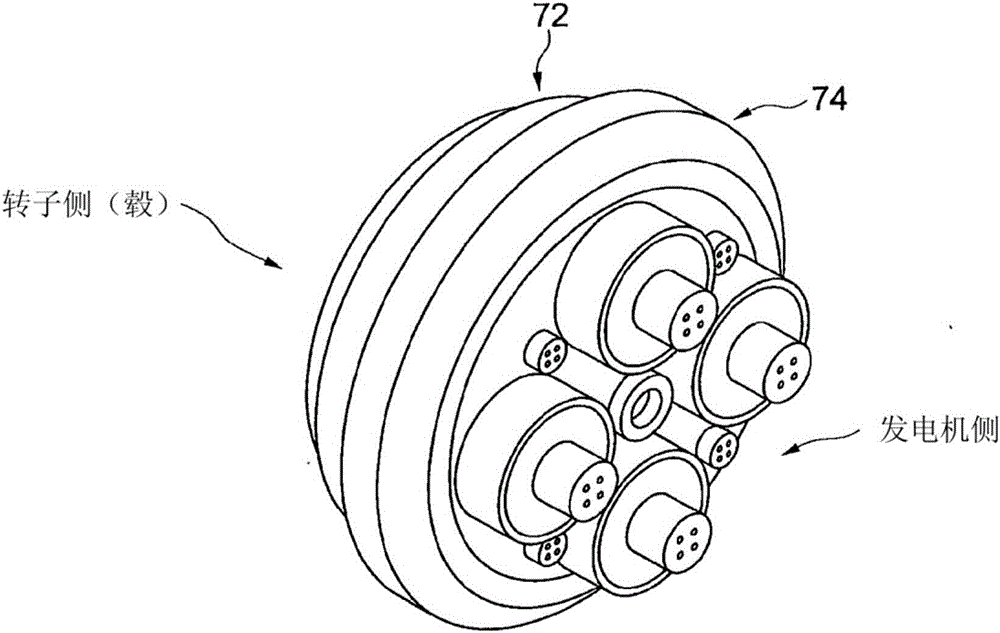

[0026] ima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com