A method for removing carbon from vanadium-containing iron water by injecting CO2 or limestone

A limestone and CO2 technology, applied in the field of metallurgy, can solve the problems of complex vanadium steel smelting process, long vanadium steel smelting process, complex iron vanadium smelting, etc., and achieve the effect of improving comprehensive utilization rate, improving utilization rate and shortening smelting cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

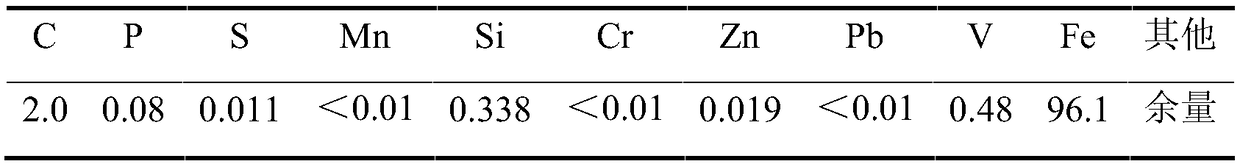

[0039] The specific composition of the blast furnace vanadium-containing molten iron in the embodiment of the present invention is shown in Table 1.

[0040] Table 1 Contents of elements in blast furnace vanadium-containing molten iron (mass fraction, %)

[0041]

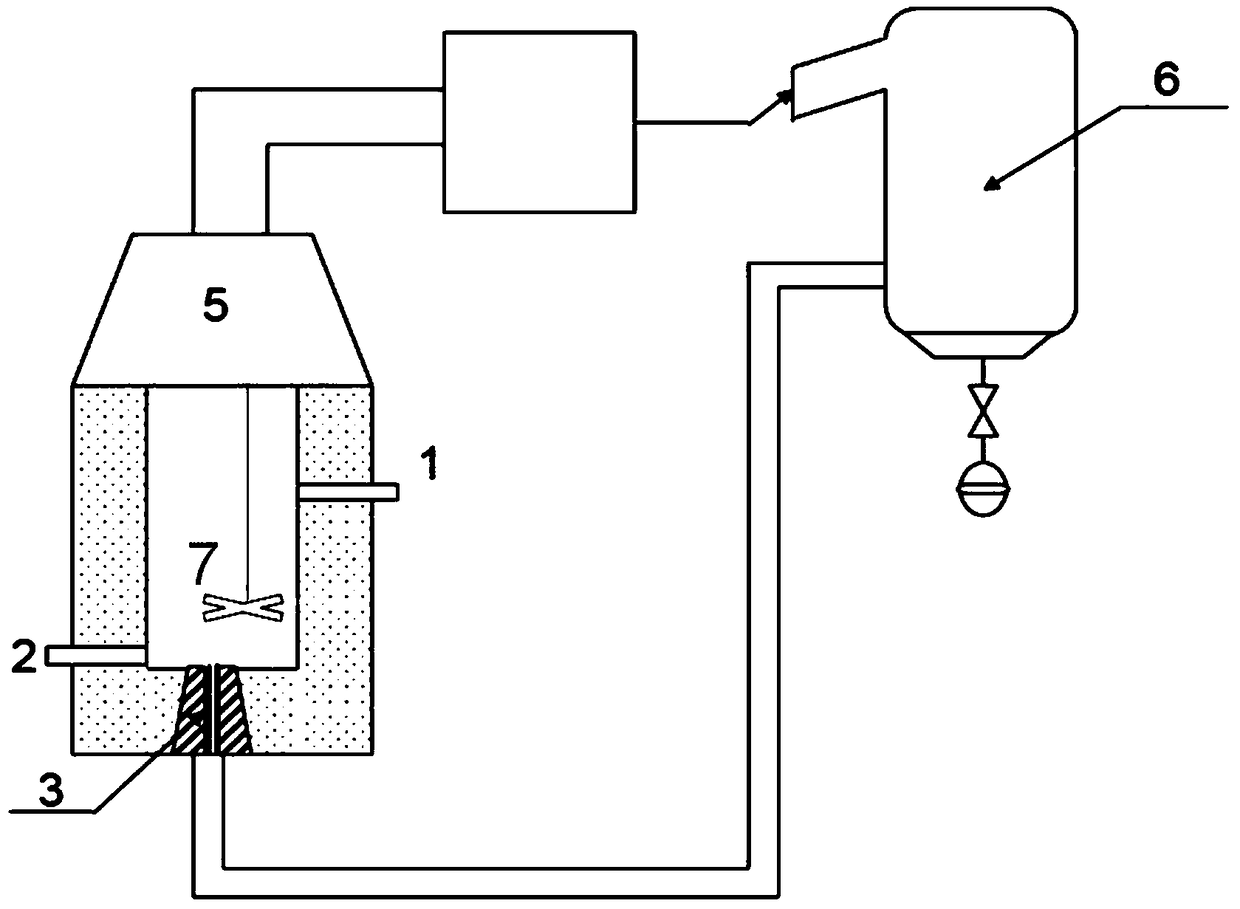

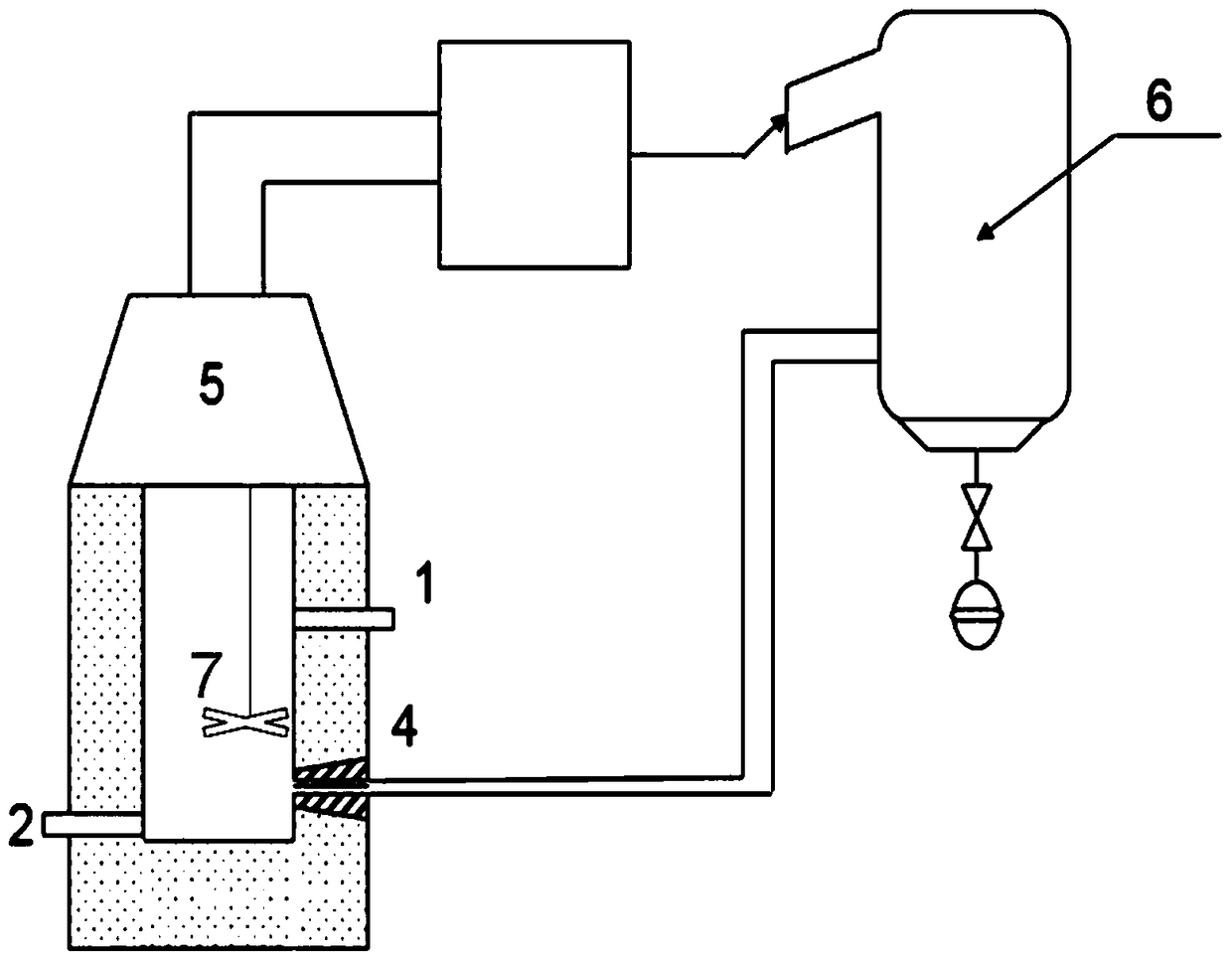

[0042] The structural schematic diagram of the induction furnace system adopted in this embodiment is shown in figure 1 .

[0043] A blown CO 2 Or the method for removing carbon from vanadium-containing iron water by limestone, comprising the following steps:

[0044] (1) The vanadium-containing molten iron obtained by reducing the slag obtained from blast furnace ironmaking at a temperature of 1450°C is introduced into the induction furnace to ensure that the temperature of the vanadium-containing molten iron is 1450°C, wherein the mass percentage of carbon in the vanadium-containing molten iron is 2.0%, the vanadium-containing mass fraction is 0.48%;

[0045] (2) Adjust the stirring paddle 7 to be inserted ...

Embodiment 2

[0050] The specific composition of the blast furnace vanadium-containing molten iron in the embodiment of the present invention is shown in Table 2.

[0051] Table 2 Contents of elements in blast furnace vanadium-containing molten iron (mass fraction, %)

[0052]

[0053] The structural schematic diagram of the induction furnace system adopted in this embodiment is shown in figure 1 .

[0054] A blown CO 2 Or the method for removing carbon from vanadium-containing iron water by limestone, comprising the following steps:

[0055] (1) The vanadium-containing molten iron obtained by reducing the slag obtained from blast furnace ironmaking at a temperature of 1500°C is introduced into the induction furnace to ensure that the temperature of the vanadium-containing molten iron is 1550°C, wherein the mass percentage of carbon in the vanadium-containing molten iron is 3.4%, the vanadium-containing mass fraction is 0.51%;

[0056] (2) Adjust the stirring paddle 7 to be inserted ...

Embodiment 3

[0061] The specific composition of the blast furnace vanadium-containing molten iron in the embodiment of the present invention is shown in Table 1.

[0062] Table 3 Contents of elements in blast furnace vanadium-containing molten iron (mass fraction, %)

[0063]

[0064] The structural schematic diagram of the induction furnace system adopted in this embodiment is shown in figure 1 .

[0065] A blown CO 2 Or the method for removing carbon from vanadium-containing iron water by limestone, comprising the following steps:

[0066] (1) The vanadium-containing molten iron obtained by reducing the slag obtained from blast furnace ironmaking at a temperature of 1650°C is introduced into the induction furnace to ensure that the temperature of the vanadium-containing molten iron is 1700°C, wherein the mass percentage of carbon in the vanadium-containing molten iron is 4.8%, the vanadium-containing mass fraction is 0.49%;

[0067] (2) Adjust the stirring paddle 7 to be inserted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com