A wheel hub heat treatment device and a treating method

A heat treatment device and wheel hub technology, applied in the field of heat treatment, can solve the problems of low heating efficiency, high structural cost, complex structure, etc., and achieve the effects of reasonable structural design, high heat treatment and air cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

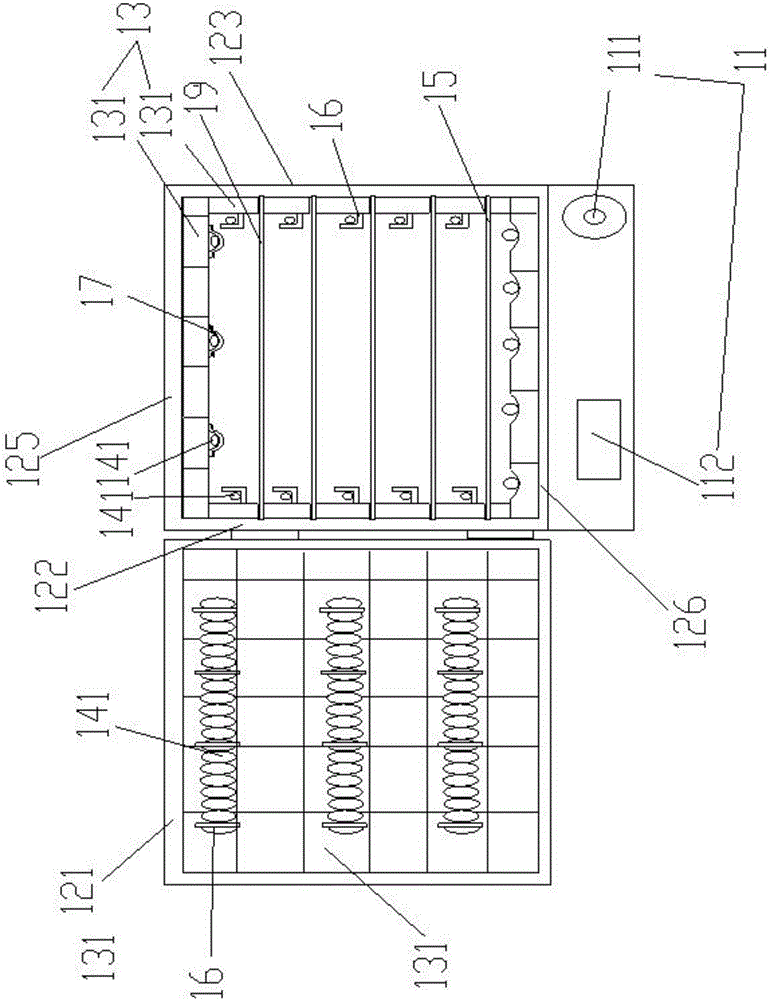

[0033] The embodiment of the present invention discloses a hub heat treatment device, including a first box-type resistance furnace 1, a quenching pool 2, a second box-type resistance furnace 3 and an air cooling device 4, the first box-type resistance furnace 1 and the second box-type resistance furnace The resistance furnace 3 is used to heat the workpiece, the quenching pool 2 rapidly cools the workpiece, and the air cooling device 4 air cools the workpiece.

[0034] The quenching pool 2 is existing equipment.

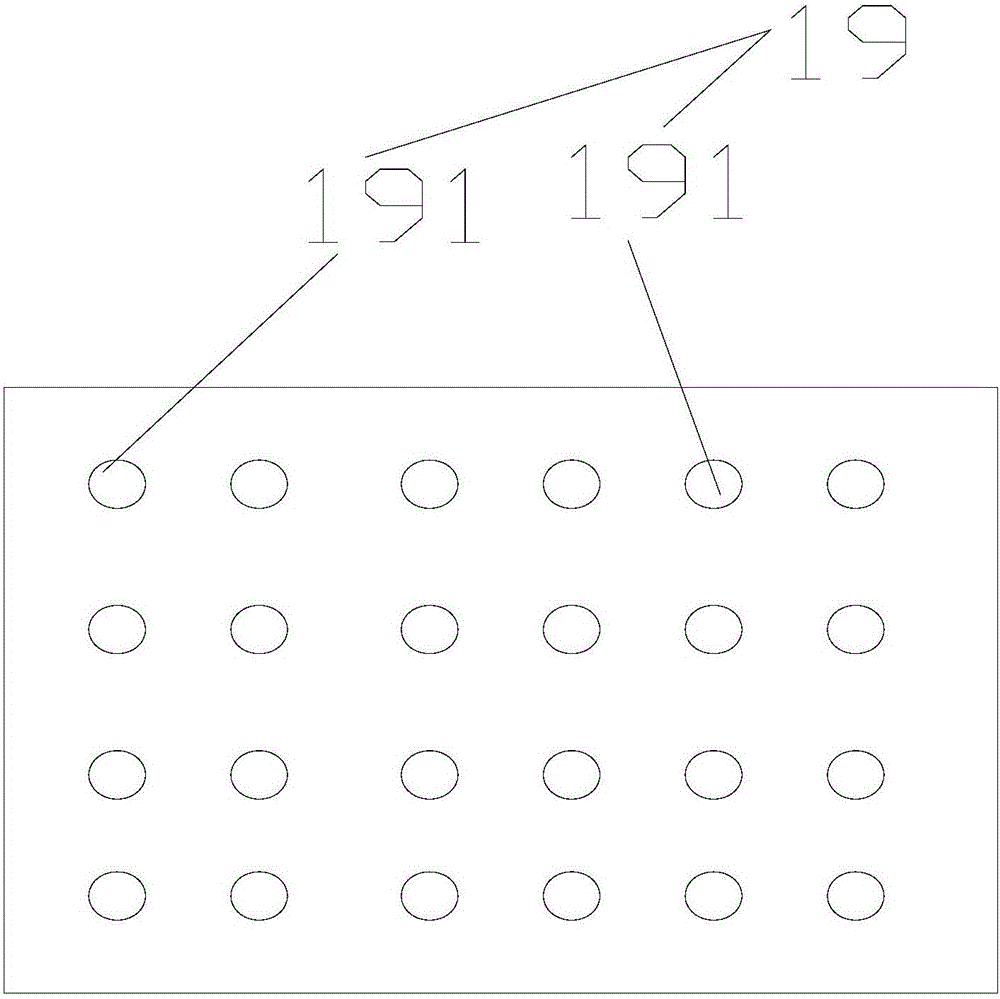

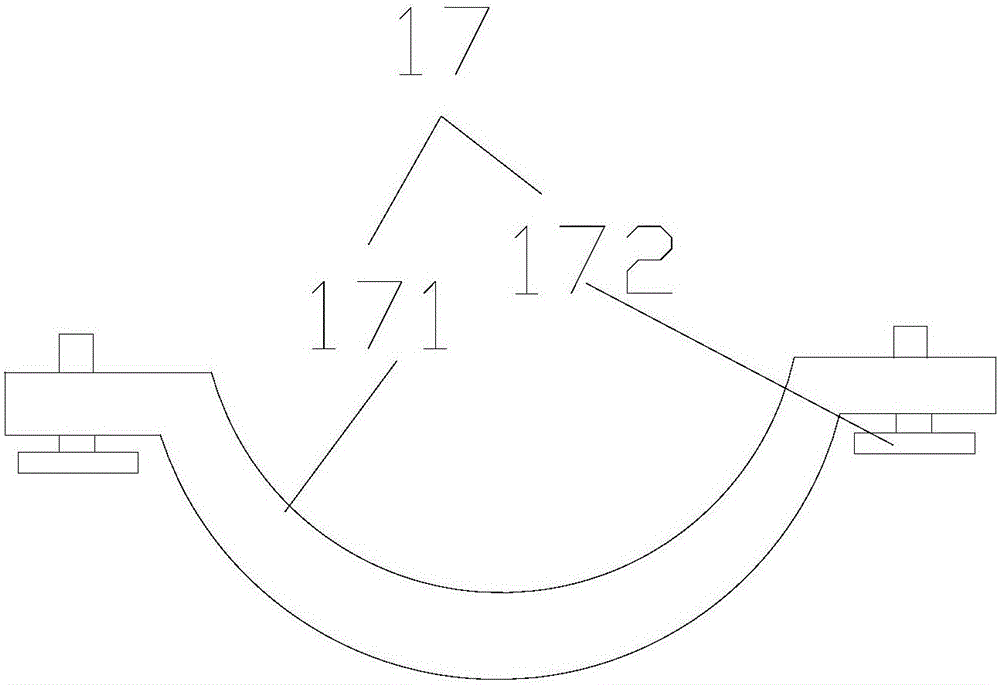

[0035] The first box-type resistance furnace 1 and the second box-type resistance furnace 2 have the same structure, and this embodiment describes the first box-type resistance furnace 1 in detail. The first box-type resistance furnace 1 includes a furnace body 11 and a furnace 12. The furnace 12 is composed of a front furnace wall 121, a left furnace wall 122, a right furnace wall 123, a rear furnace wall 124, and a top furnace wall provided with a furnace door. 1...

Embodiment 2

[0043] The embodiment of the present invention discloses a hub heat treatment device, including a first box-type resistance furnace 1, a quenching pool 2, a second box-type resistance furnace 3 and an air cooling device 4, the first box-type resistance furnace 1 and the second box-type resistance furnace The resistance furnace 3 is used to heat the workpiece, the quenching pool 2 rapidly cools the workpiece, and the air cooling device 4 air cools the workpiece.

[0044] The quenching pool 2 is existing equipment.

[0045] The first box-type resistance furnace 1 and the second box-type resistance furnace 2 have the same structure, and this embodiment describes the first box-type resistance furnace 1 in detail. The first box-type resistance furnace 1 includes a furnace body 11 and a furnace 12. The furnace 12 is composed of a front furnace wall 121, a left furnace wall 122, a right furnace wall 123, a rear furnace wall 124, and a top furnace wall provided with a furnace door. 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com