A device and method for measuring the mixed medium of refrigerating machine oil and refrigerant

A technology for refrigerating machine oil and mixed medium, which is used in measuring devices, DC flow characteristics measurement, material weighing, etc., can solve the problems of large test pressure limitation, inability to measure the viscosity index of mixed solution, etc., and achieves simple structure and measurement application range. Wide, test reproducible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

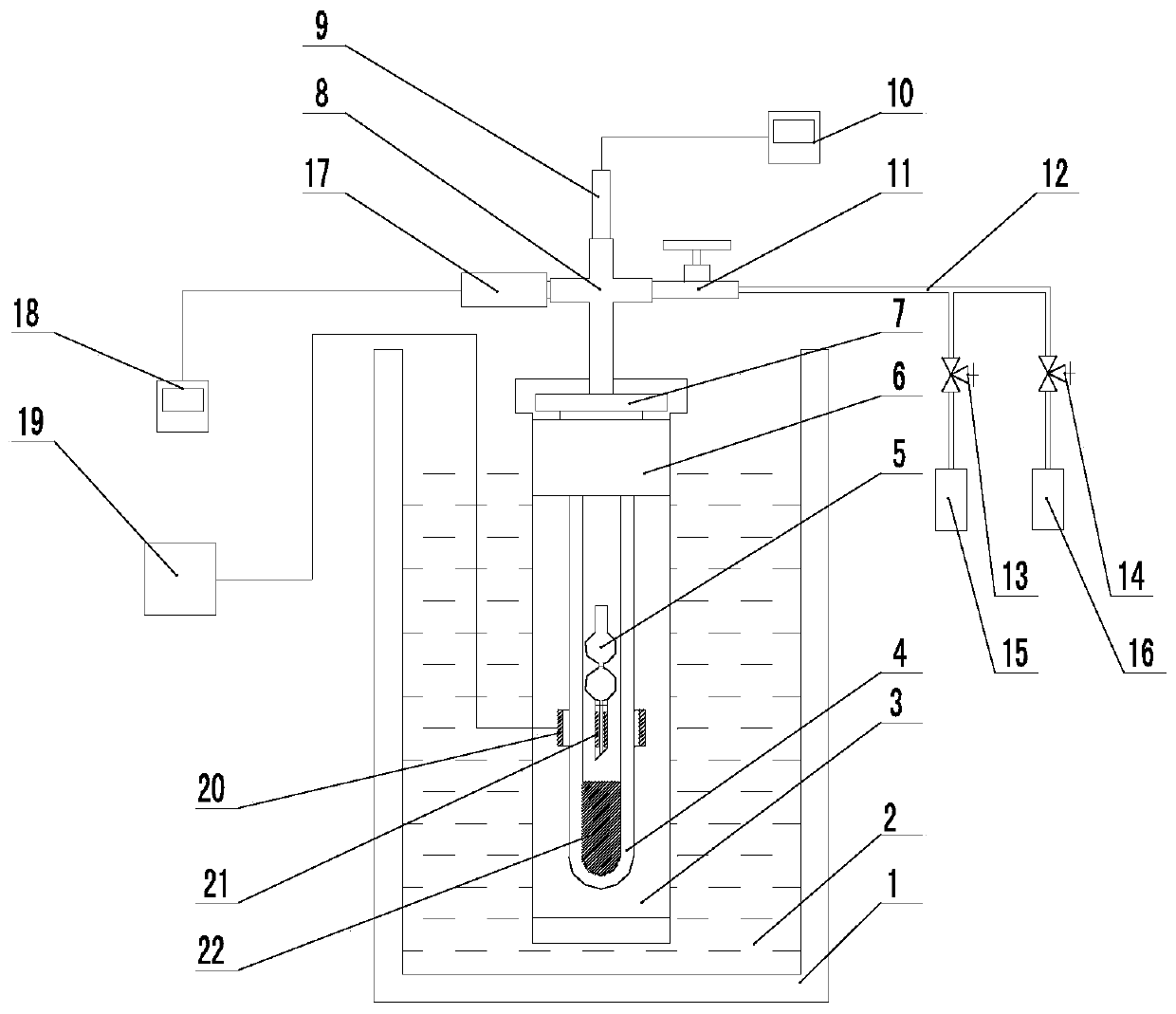

[0034] The invention provides a device for measuring the mixed medium of refrigerating machine oil and refrigerant, comprising a constant temperature system and a high-pressure sealed container arranged in the constant temperature system, the high-pressure sealed container includes a pressure-resistant glass tube 4, and the pressure-resistant glass tube 4 A viscosity testing device is provided inside, and the viscosity testing device includes a capillary viscometer 5 and a lifting device, the capillary viscometer 5 is located inside the pressure-resistant glass tube 4, and the lifting device includes a The magnet 20 moving up and down along the tube wall and the metal 21 arranged inside the pressure-resistant glass tube 4 and connected to the capillary viscometer 5 can drive the capillary viscometer 5 to move up and down under the adsorption of the magnet 20 . The metal 21 is wrapped in the lower part of the capillary viscometer 5 with the structure of a metal ring, the metal r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com