Touch substrate shadow elimination detection method and manufacturing method, touch substrate and touch device

A detection method and substrate technology, applied in circuit inspection/recognition, instruments, printed circuit components, etc., can solve the problems of large grade judgment errors, production losses, and inability to eliminate shadows in visual inspection, and achieve accurate shadow elimination. The effect of grade determination and production loss avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order for those skilled in the art to better understand the solution of the present invention, the touch substrate disappearing detection method, the touch substrate manufacturing method, the touch substrate and the touch The device is described in further detail. Apparently, the described and illustrated embodiments and various specific features therein are only illustrative illustrations of the present invention, rather than limiting the present invention. Based on the exemplary descriptions, all other embodiments and specific features obtained by persons of ordinary skill in the art without creative efforts fall within the protection scope of the present invention.

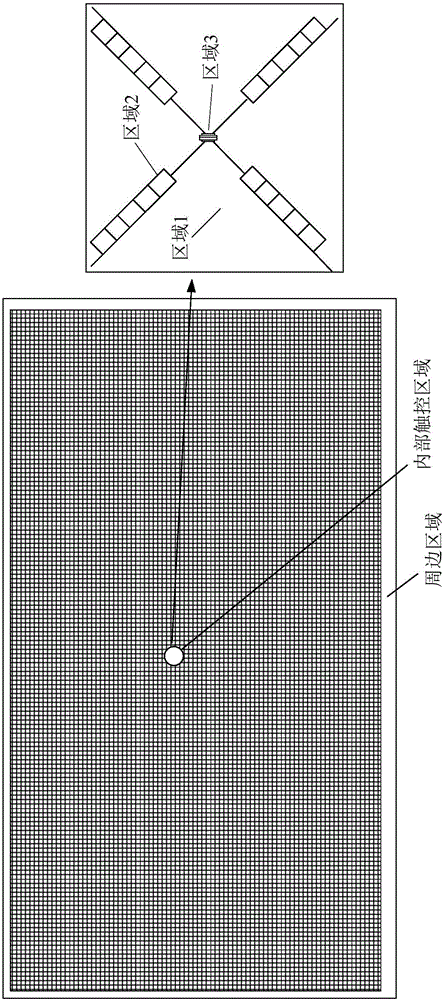

[0015] Now refer to figure 1 , which shows the internal touch viewable area of a single OGS touch substrate. Such as figure 1 As shown in , the internal touch visible area includes the following three different stacked structure areas: area 1, area 2, and area 3. Among them, area 1 may include a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com