Rotating cutter type overhead transmission line deicing and snow removal device

A technology of overhead transmission lines and rotary cutters, which is applied in the field of deicing and snowing on transmission lines, can solve the problems of high operating intensity, damage to deicing mechanism, and low operating efficiency, and achieve the effects of high degree of automation, convenient installation, and thorough deicing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to facilitate those of ordinary skill in the art to understand and implement the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, but the embodiments of the present invention are not limited thereto.

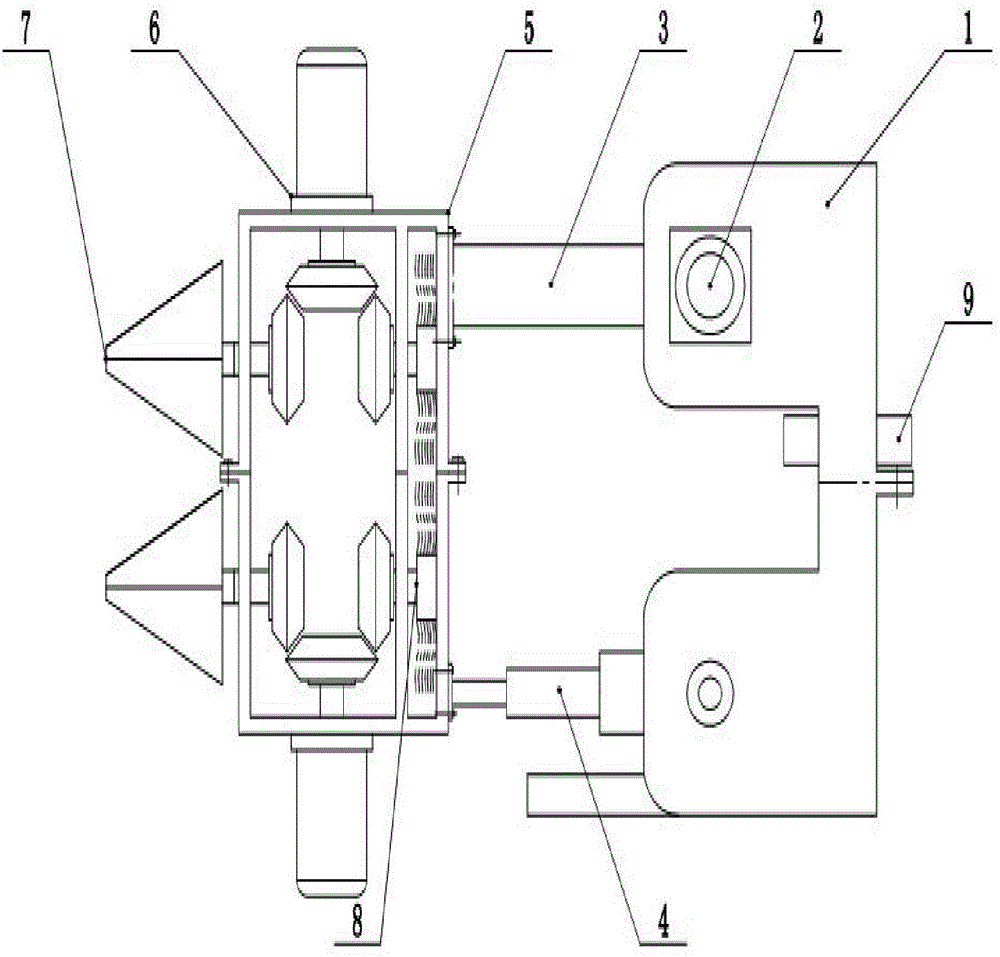

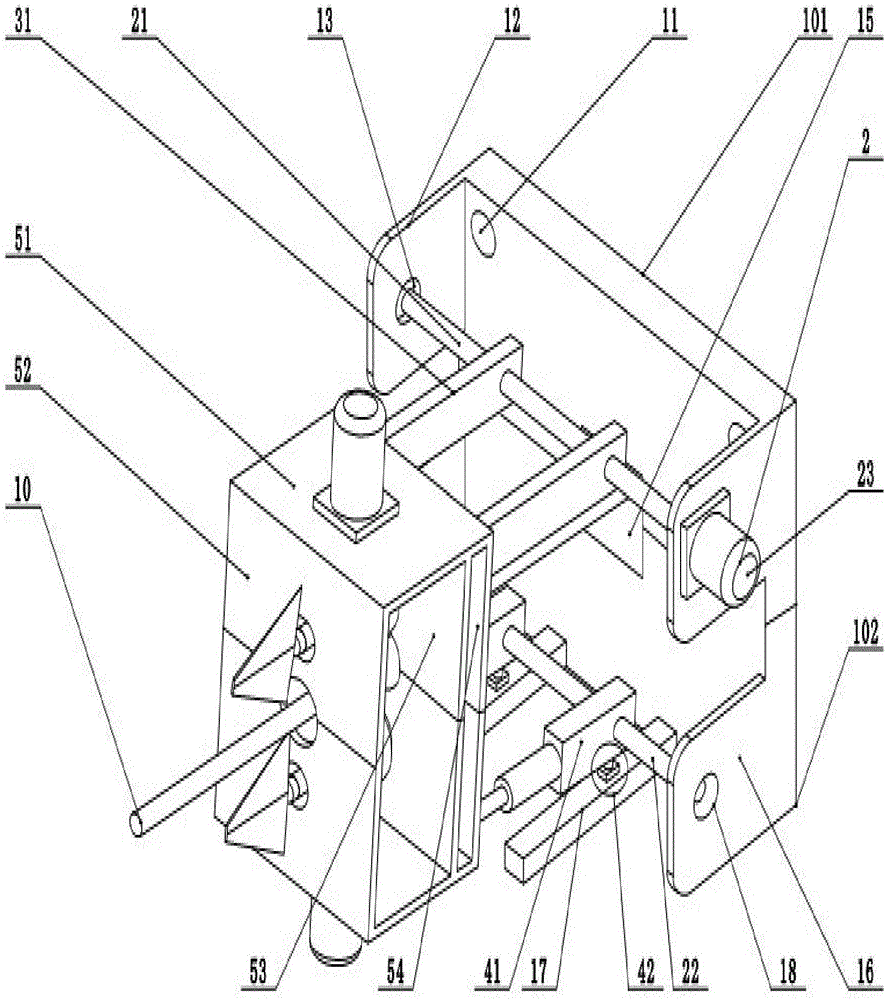

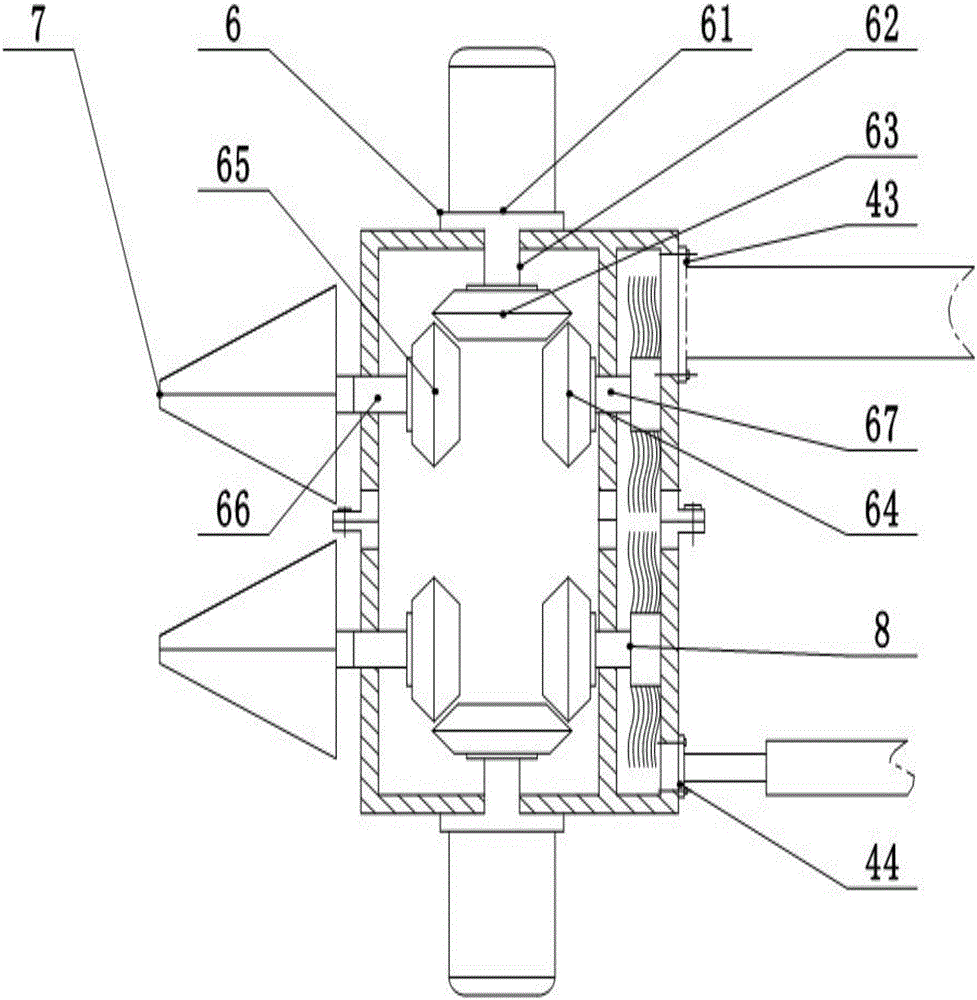

[0037] as attached figure 1 As shown in -8, a rotary cutter type overhead transmission line deicing device is characterized in that it includes a deicing mechanism mounting seat 1, a rotating drive device 2, a rotating support device 3, a rotating auxiliary device 4, and a deicing frame 5 , deicing driving device 6, deicing device and angle measuring device 9, the angle measuring device 9 measures the angle of the power line 10 and the horizontal direction deviation, the rotating driving device 2 drives the rotating supporting device 3 to make the deicing frame 5 and The deicing device is parallel to the power line, and the deicing driving device 6 drives the deicing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com