Garment dimension automatic measurement system based on machine vision and measurement method thereof

A technology of machine vision and automatic measurement, which is applied to instruments, tools for sewing clothes, image enhancement, etc., and can solve problems such as high error rate, high cost, and slow detection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The present invention will be described in detail below with reference to the drawings and specific embodiments.

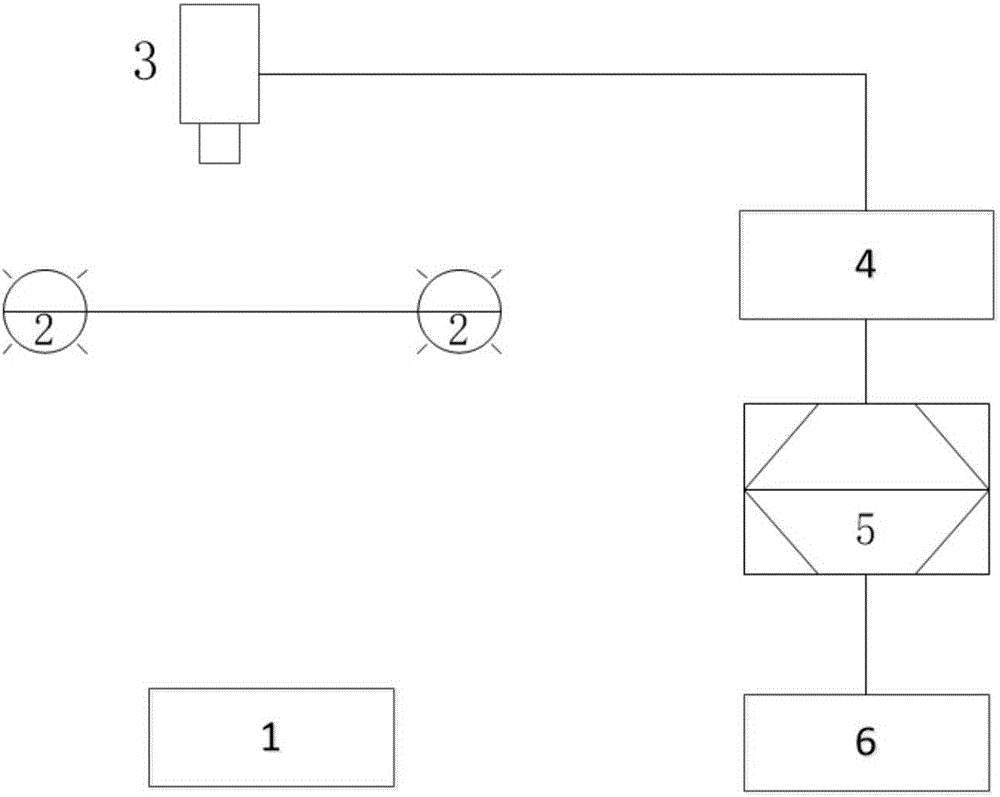

[0064] A clothing size automatic measurement system based on machine vision, such as figure 1 As shown, it includes an inspection station 1, a light source 2 and a CCD camera 3. A light source 2 is arranged above the inspection station 1, a CCD camera 3 is arranged above the light source 2, and the CCD camera 3 is connected to the image acquisition card 4, and the image acquisition card 4 is connected to the The computer 5 is connected, and an output device 6 is also connected to the computer 5.

[0065] Among them, the output device may be a printer.

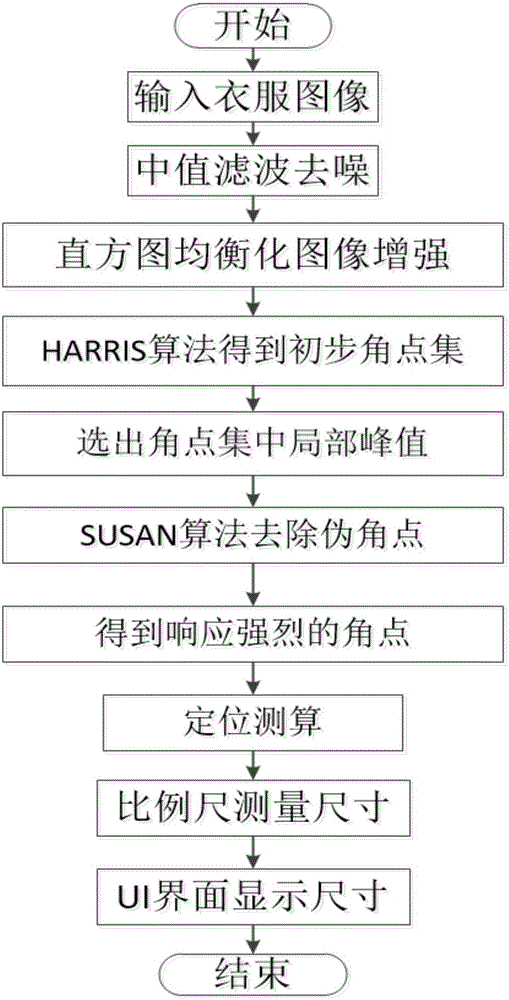

[0066] An automatic measurement method of clothing size based on machine vision using the above measurement system, such as figure 2 As shown, follow the steps below:

[0067] Step 1. Perform image collection on clothes that need size measurement;

[0068] Put the clothes to be measured on the background plate of ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap