Micro-amplitude angular vibration exciter

An angular vibration and exciter technology, which is applied in the direction of the fluid using vibration, can solve the problem of unable to meet the needs of the angular vibration simulation test of the moving parts on the satellite, and meet the requirements of micro-angle vibration amplitude and accuracy, and the manufacturability Good, stiffness-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

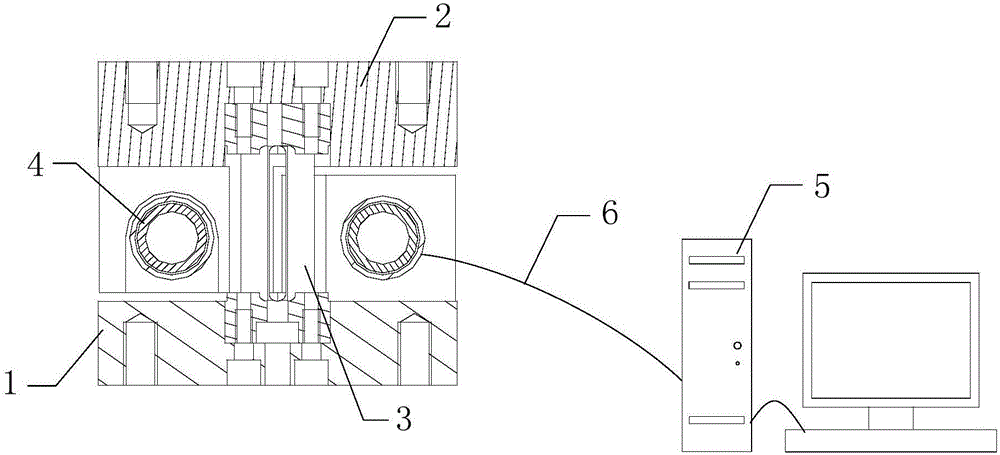

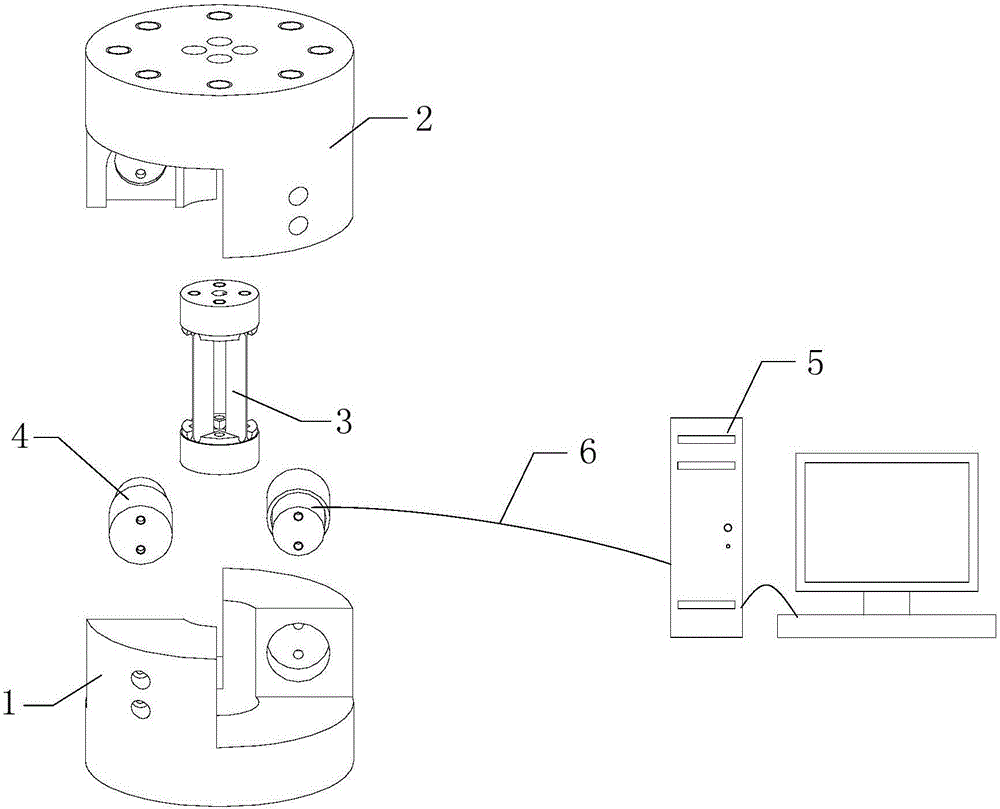

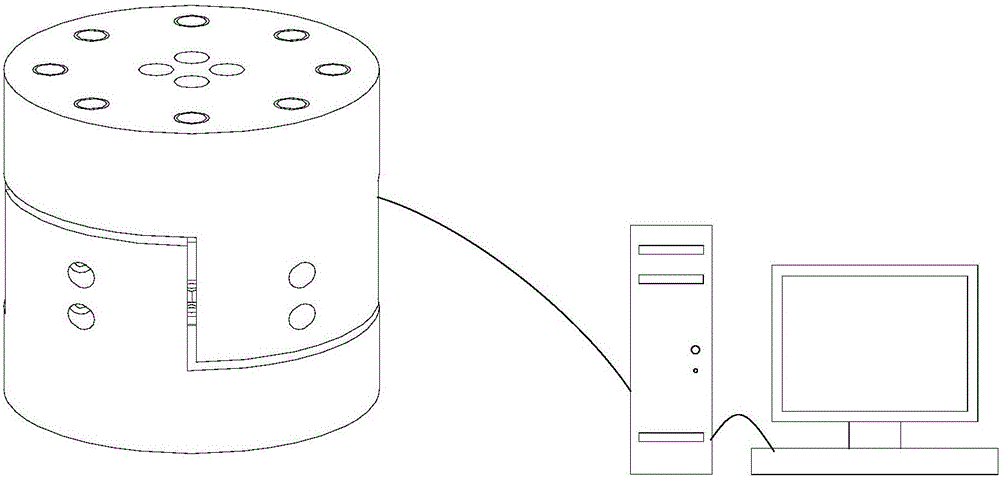

[0045] In the embodiment of the present invention, there are 2 voice coil motors 4, the base 1 is cylindrical, and there are fan-shaped bosses in two opposite quadrant areas, and the mover 2 is also cylindrical, with fan-shaped bosses in the other two opposite quadrant areas. There is a circular hole on both sides of the fan-shaped boss of the base 1 and the mover 2, which is used to place two voice coil motors 4 horizontally. The fixed end 41 of the voice coil motor 4 is fixed to the two sides of the boss of the base 1 by screws. In the hole, the movable end 42 is fixed in the two holes on the side of the boss of the mover 2 by screws, and the central cylindrical area formed by the combination of the base 1 and the fan-shaped boss of the mover 2 is installed with the flexible hinge 3; Both 31 and the lower mounting platform 32 are cylindrical, and are respectively fixed on the base 1 and the mover 2 through four mounting holes. Considering the convenience of processing, the n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com