A tool detection instrument for CNC punching press mold and a method for detecting and setting tools

A technology of CNC punching machine and tool setting instrument, which is applied in the direction of manufacturing tools, forming tools, metal processing, etc., can solve the problem of low installation accuracy, and achieve the effects of reducing labor intensity, easy production, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

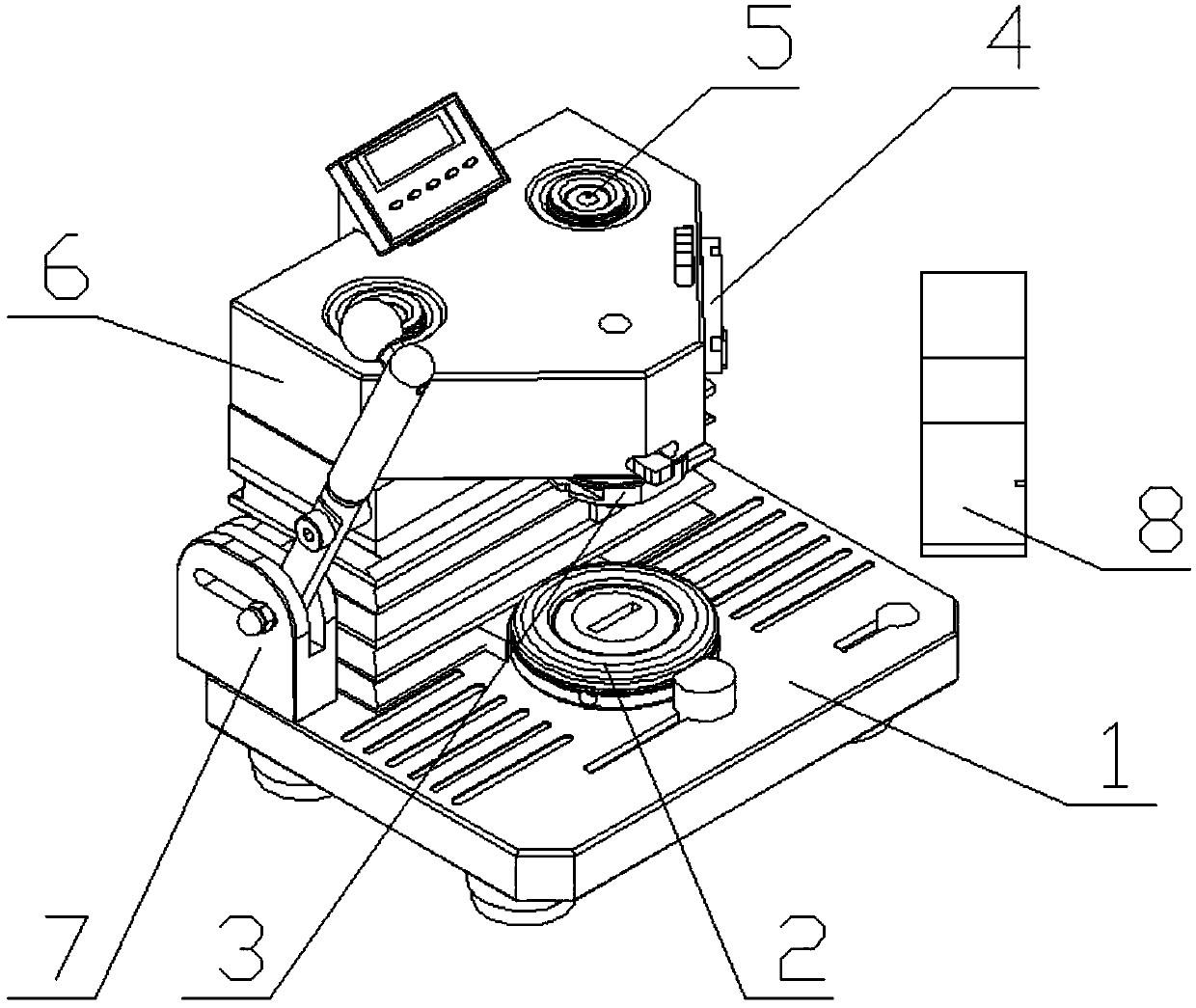

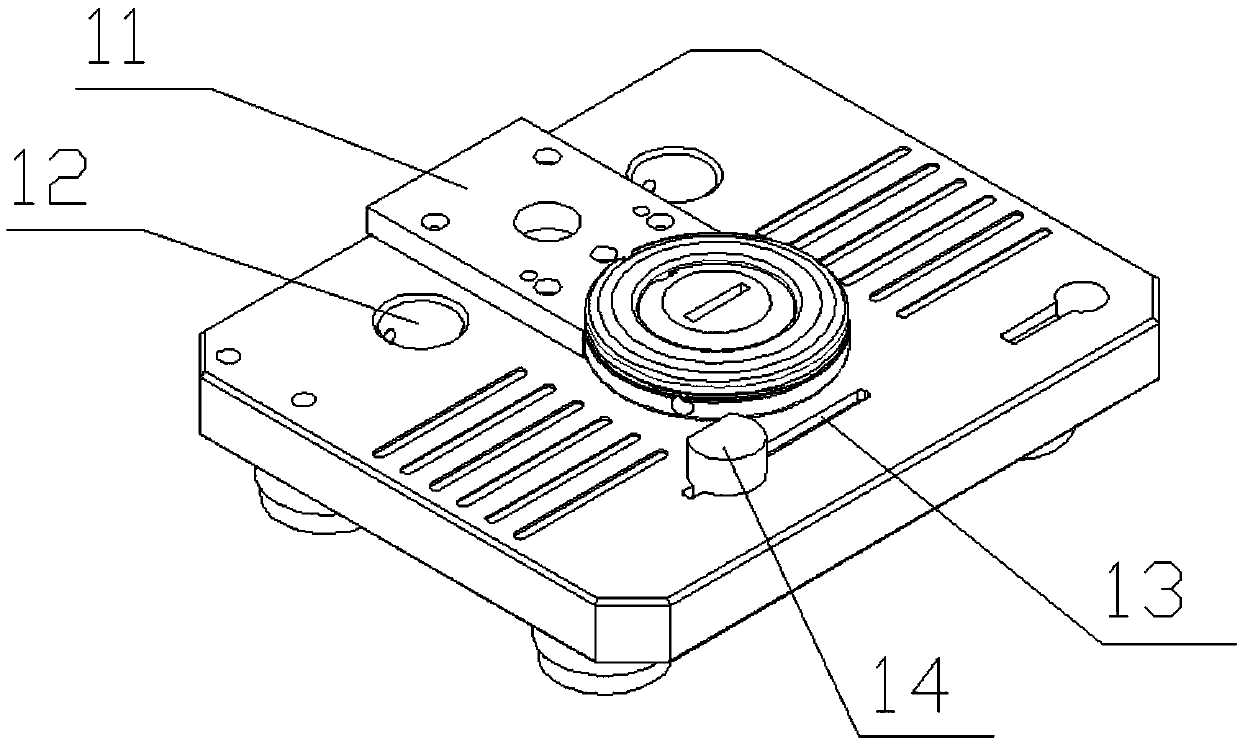

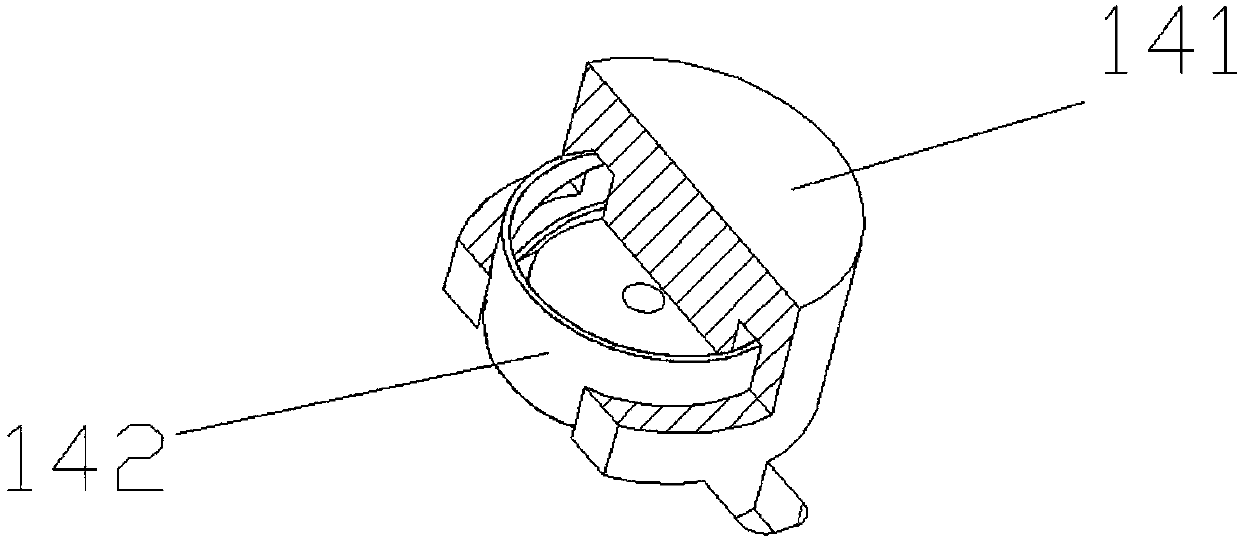

[0047] like figure 1 As shown in the figure, a tool setting instrument for CNC punching press mold includes a base 1, a lower mold base 2, a vertical upper mold base 3, a horizontal upper mold base 4, a guide post 5, a lifting table 6, a lifting traction device 7 and a tool setting block 8; if figure 2 As shown, one end of the base 1 is fixed with a limiting block 11 by bolts, and the other end is provided with a tightening groove 13; the lower mold base 2 is arranged between the limiting block 11 and the tightening groove 13; the shape of the lower mold base 2 is It is circular, and the end of the limit block 11 in contact with the lower mold base 2 is also set as a circular groove, which can accurately locate the lower mold base 2, so that the axis position of the lower mold base 2 has a higher accuracy; A tight block 14 for fixing the lower mold base 2 is arranged on the fixed groove 13; image 3As shown, the tightening block 14 includes a housing 141; the lower end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com