PC (Precast Concrete) component maintaining system used for building

A maintenance system and construction technology, applied in the direction of ceramic molding machines, manufacturing tools, etc., can solve the problems that maintenance equipment cannot supply steam in time, speed up template turnover and production efficiency, speed up cement and auxiliary cementitious materials, etc., and achieve steam supply Fast and comprehensive, good maintenance effect, uniform distribution of fog points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further explained below in conjunction with specific embodiments.

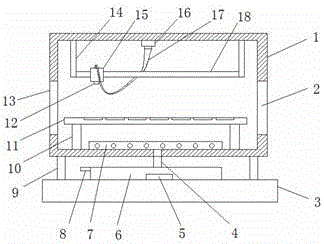

[0015] refer to figure 1 , a maintenance system for building PC components proposed by the present invention, comprising a box body 1 for PC component maintenance, the lower end of the box body 1 is connected with a base 3 through a support frame 9, and the upper end of the base 3 is provided with a storage tank for water storage. Water tank 6, one side upper end of water storage tank 6 is provided with water inlet pipe 8, is used for water intake, and the bottom in water storage tank 6 is equipped with heating device 5, and the upper end of water storage tank 6 is provided with connecting pipe 4, and casing 1 is fixed with a steam pipe 7 and two fixed frames 10, the steam pipe 7 is located between the two fixed frames 10, a plurality of steam holes are arranged at equal intervals on the steam pipe 7, and the connecting pipe 4 is far away from the water storage tank 6. One...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com