Discharging cooling device of preforming machine

A preformer and cooling device technology, which is applied to other household appliances, household components, household appliances, etc., can solve the problems of surface deformation of rubber rings, accumulation of rubber rings, incomplete cooling, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

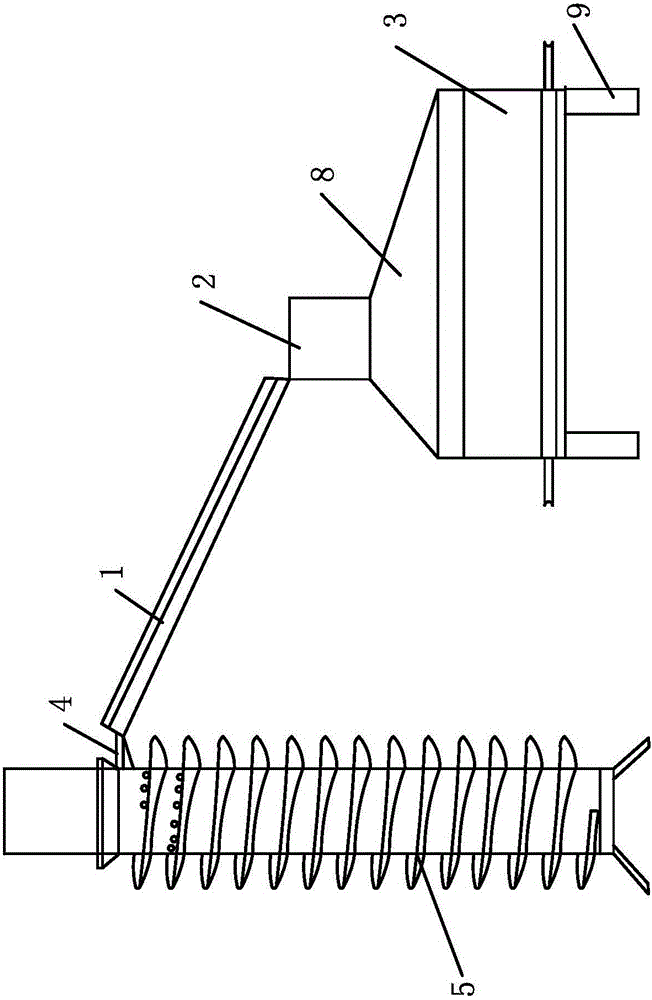

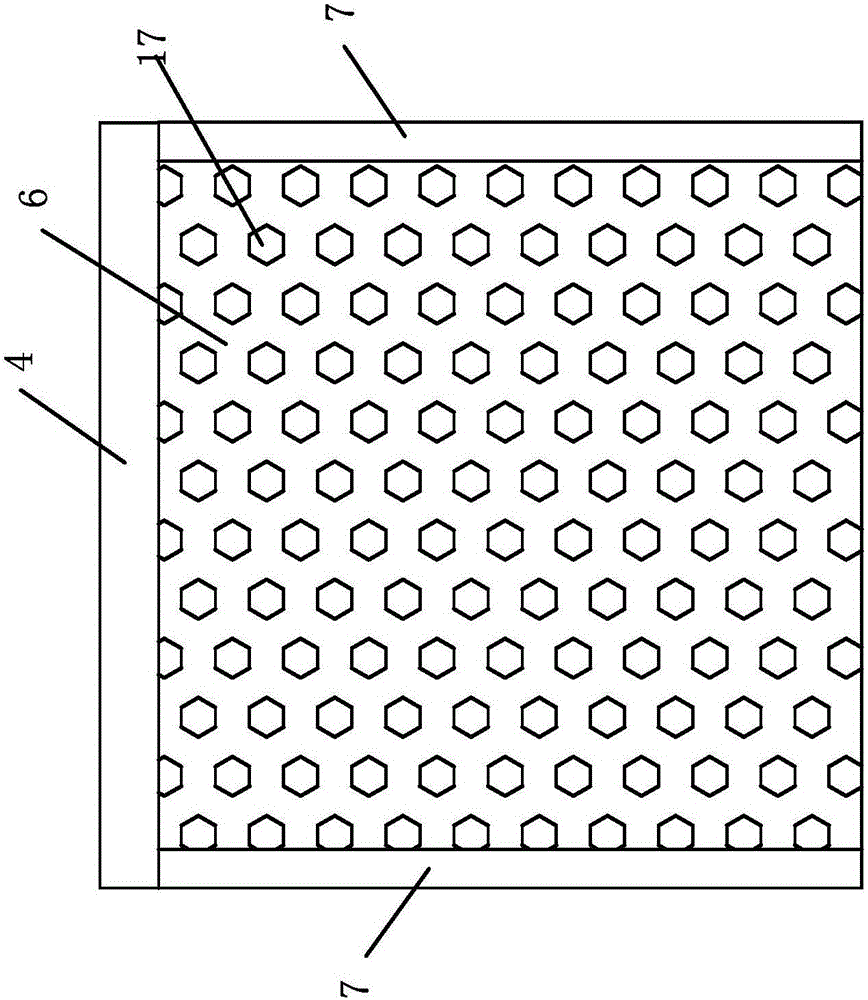

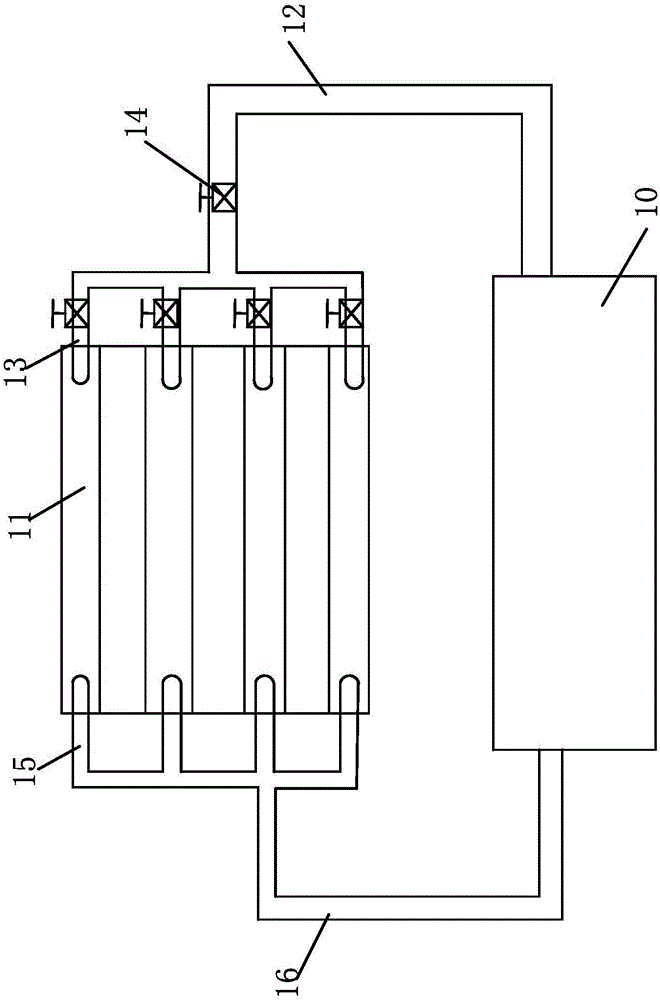

[0022] Such as Figure 1-3 As shown, the technical solution of the present invention is a discharge cooling device for a preforming machine, including a guide plate 1, a buffer tank 2 and a receiving tank 3, and one end of the guide plate 1 is connected to the connecting plate 4 and the molding machine 5. The outlet is connected, the other end of the guide plate 1 is connected to the upper end of the buffer tank 2, the guide plate 1 is inclined towards the buffer tank 2, the guide plate 1 includes a bottom plate 6, and the two sides of the bottom plate 6 Side plates 7 are respectively provided at the ends, and the bottom plate 6 is provided with ventilation holes 17. The upper and lower ends of the buffer tank 2 are openings, and the openings at the lower end are connected with the conical hollow cavity 8. The conical The upper and lower ends of the hollow cavity 8 are open, and the openings at the lower end are connected to the upper 3 ends of the material receiving trough, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com