Environment-friendly crushing device

A pulverizing device, an environmentally friendly technology, applied in mixers with rotary stirring devices, transportation and packaging, dissolving and other directions, can solve the problems of reduced production efficiency, affecting pulverization accuracy, etc., to extend service life, improve production efficiency, maintain internal effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

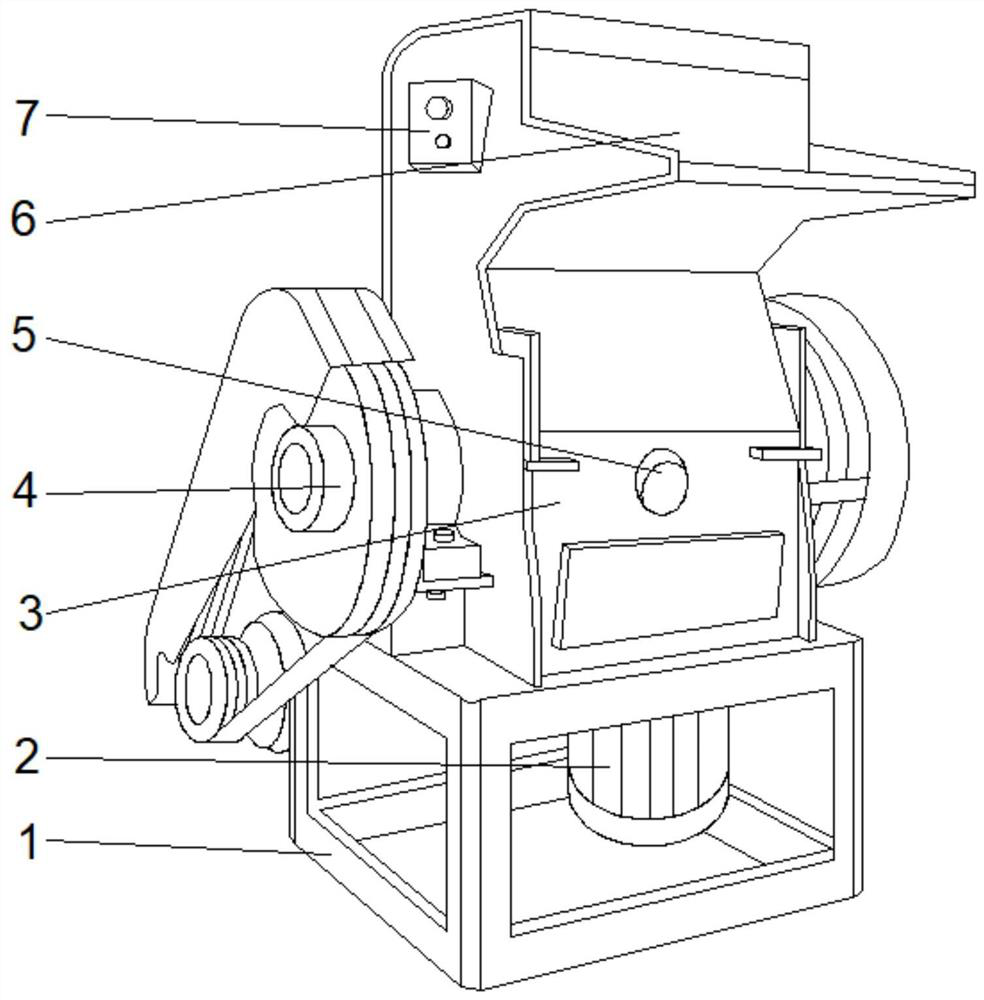

[0033] see Figure 1-2 , the present invention provides a technical solution: an environmentally friendly crushing device, including a base 1, a stirring motor 2 is provided in the middle of the top of the inner cavity of the base 1, a crushing device 3 is fixedly connected to the top of the base 1, and the front bottom of the crushing device 3 A water inlet 5 is provided in the middle position, a power mechanism 4 is provided at the bottom of both sides of the outer wall of the crushing device 3, a controller 7 is fixedly connected to the middle position of the top of the left outer wall of the crushing device 3, and a feed inlet is provided at the top of the front of the crushing device 3 6.

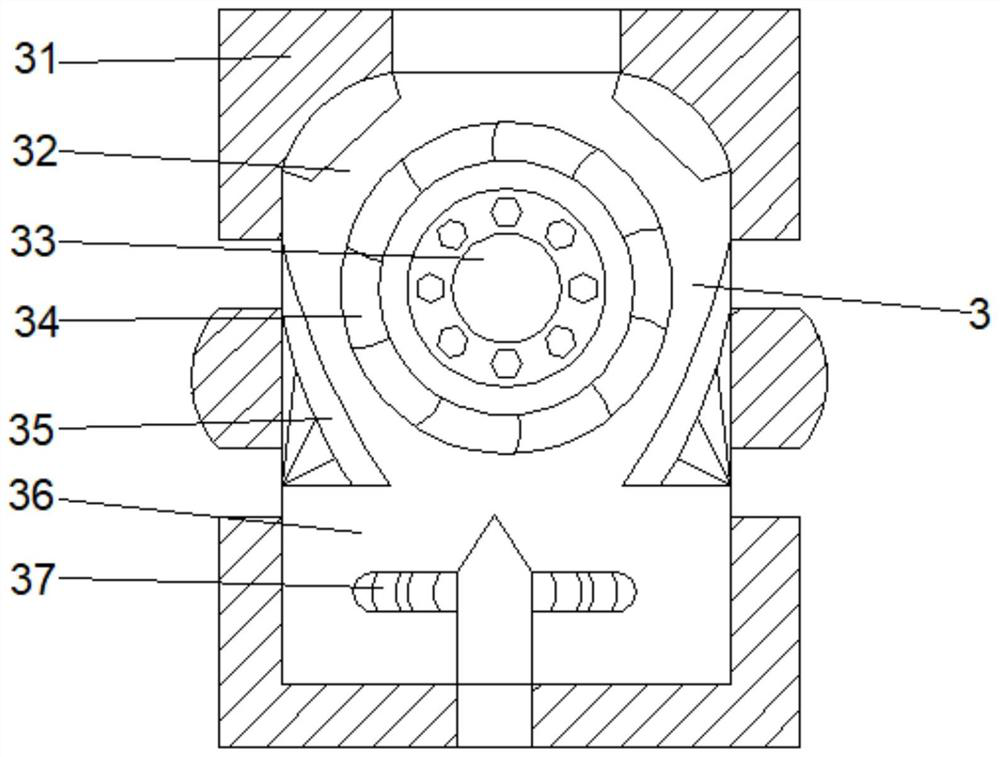

[0034] Wherein, the pulverizing device 3 comprises a casing 31, a stirring rod 37 is arranged at the bottom middle of the inner cavity bottom of the casing 31, and a collecting chamber 36 is arranged at the bottom of the inner cavity of the casing 31 at both sides of the stirring rod 3...

Embodiment 2

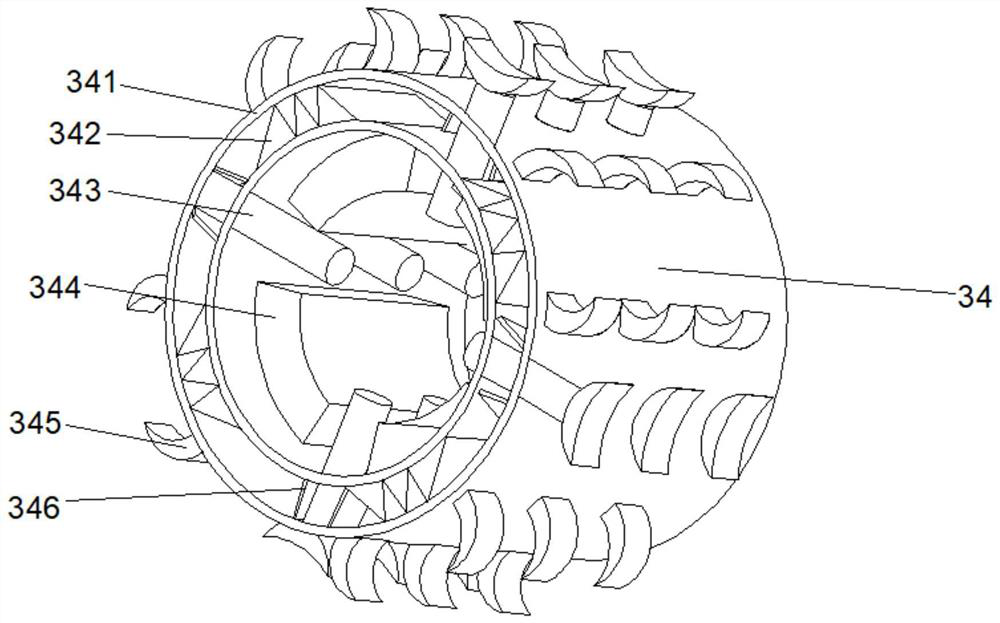

[0037] see Figure 1-4On the basis of Embodiment 1, the present invention provides a technical solution: the crushing mechanism 34 includes a crushing frame 341, the inner surface of the crushing frame 341 is provided with an auxiliary mechanism 343, and the top of the auxiliary mechanism 343 penetrates the crushing frame 341 and extends to the crushing frame 341. The outside of frame 341, the outer surface of crushing frame 341 is positioned at the both sides of auxiliary mechanism 343 and is fixedly connected with cutter 345, and the inner cavity of crushing frame 341 is positioned at the both sides of auxiliary mechanism 343 and is fixedly connected with protective plate 346, and the inner chamber of crushing frame 341 The bottom is located on both sides of the protective plate 346 and is fixedly connected with a pressure block 342 , and the inner surface of the crushing frame 341 is located on both sides of the auxiliary mechanism 343 and is fixedly connected with a linkage...

Embodiment 3

[0041] see Figure 1-6 , on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the connection mechanism d4 includes a blocking plate d45, the bottom of the inner wall on both sides of the blocking plate d45 is fixedly connected with a clamping rod d44, and the left side of the blocking plate d45 The inner wall is fixedly connected with connecting teeth d43, the inner wall on the right side of the blocking plate d45 is fixedly connected with the linkage frame d41, and the blocking plate d45 is located on both sides of the linkage frame d41 and fixedly connected with the limit block d42.

[0042] Wherein, the linkage frame d41 includes a movable rod t1, a rubber block t4 is fixedly connected to the middle of the movable rod t1, a top plate t3 is fixedly connected to the top of the rubber block t4, and a contact block t2 is arranged on the top of the top plate t3.

[0043] When in use, the inside of the device shrinks and clamps when ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com