Intelligent production fixture for injection moulding

A technology for production tooling and injection molding, applied in the field of intelligent production tooling for injection molding, can solve problems such as easy clogging of the feeding hopper, affecting the normal operation of the equipment, etc., to improve the utilization rate of thermal effects, ensure the molding effect, and facilitate disassembly and installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

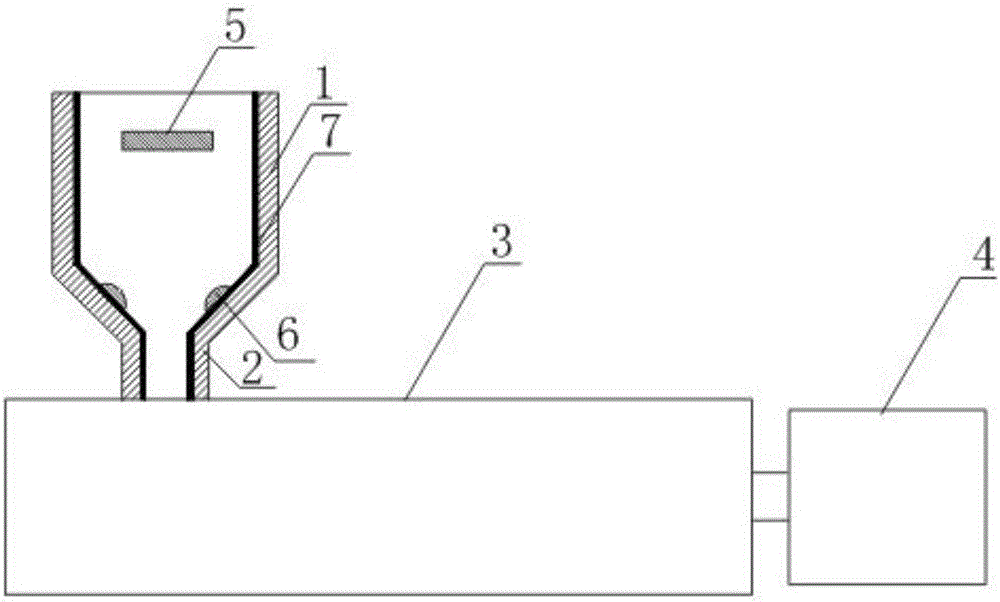

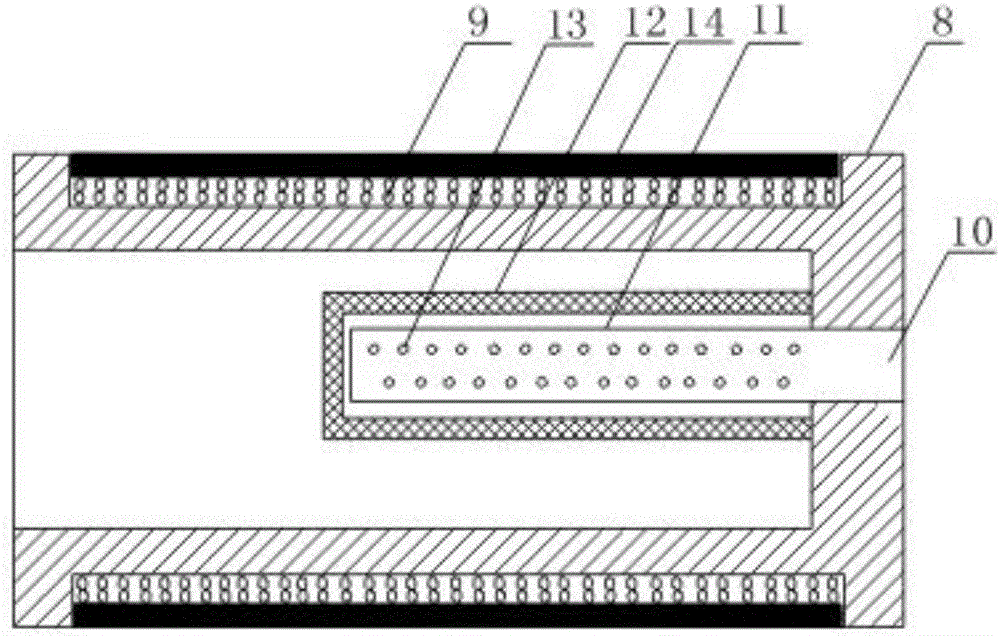

[0028] Intelligent production tooling for injection molding, including a feed hopper 1 and a buffer section 2 arranged at the lower end of the feed hopper 1, the buffer section 2 is connected with an extruder 3, and the discharge end of the extruder 3 is provided with a die head 4; The upper side wall of the feed hopper 1 is provided with a baffle plate 5, and the inner walls of both sides of the lower end of the feed hopper 1 are respectively provided with blocking strips 6; the inner walls of the feed hopper 1 and the buffer section 2 are provided with Smooth layer 7; the die head 4 includes a shell 8, an electromagnetic heating coil 9 wound on the shell 8, the front end of the shell 8 is provided with an extrusion hole 10, and the shell 8 is provided with a fixing hole communicated with the extrusion hole 10 The pipe 11 is provided with a filtering device 12 outside the fixed pipe 11, and one end of the filtering device 12 is fixed in the inner cavity of the casing 8, and se...

Embodiment 2

[0030] In this embodiment, on the basis of Embodiment 1, the filter device 12 is a filter net.

Embodiment 3

[0032] On the basis of Embodiment 1 or Embodiment 2, this embodiment further includes an insulating layer 14 arranged outside the electromagnetic heating coil 9 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com