Hot melting film cutting device for film drawing packing machine

A film device and hot-melt technology, applied in the field of packaging, can solve the problems of failure, insufficient packaging amount, waste of materials, etc., and achieve the effect of reasonable design and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

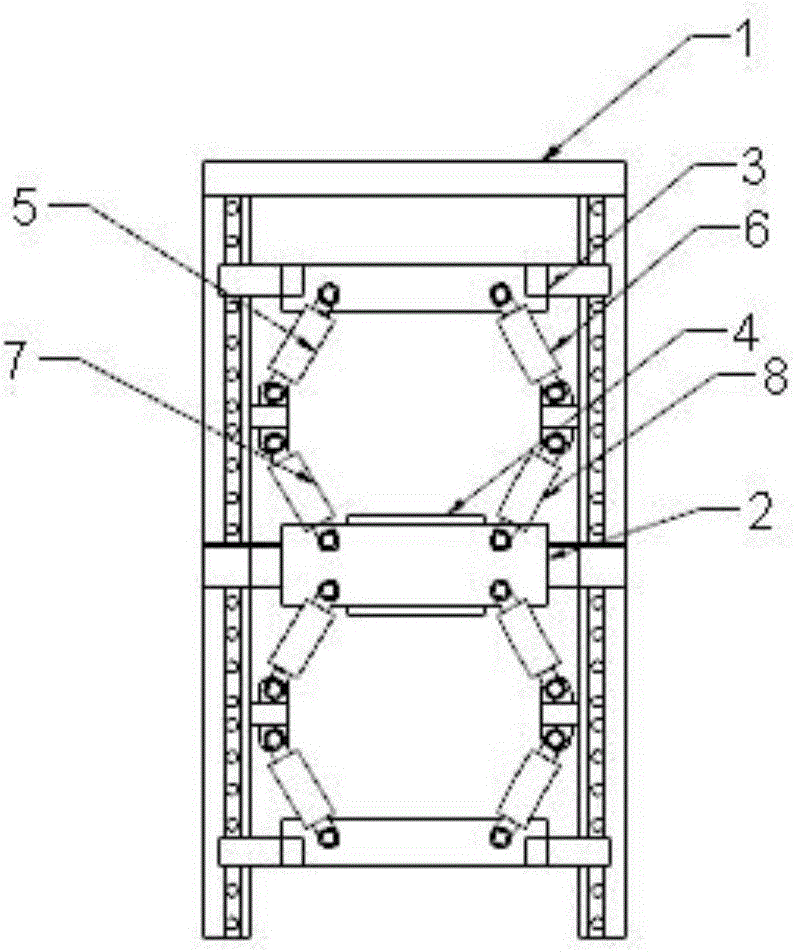

[0014] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

[0015] A hot-melt film cutting device for a stretch film packaging machine, comprising a film cutting support 1, on which a fuse seat 2 and a pressing seat 3 are provided, and two sets of pressing seats 3 are provided to fuse The seat 2 is arranged symmetrically up and down in the center, and the press-fit seat 3 is away from or close to the fuse seat 2 under the action of the press-fit drive device, and the upper and lower sides of the fuse seat 2 are respectively provided with fuses 4 communicating with the external power supply .

[0016] Pass the upper film between the fuse seat 2 of the fuse device and the pressing seat 3 above it, and apply it to the packaging production of the packaging machine, and the lower film pass between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com