Cerium-containing electrode used for electrolysis and preparation method thereof

An electrode and electroplating solution technology, applied in the field of electrodes for electrolysis of water electrolysis and its preparation, can solve the problem of high electrode cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of the cerium-containing electrode for electrolysis of the present invention includes the following steps: (1) the pretreatment step of stainless steel substrate; (2) the formation step of titanium dioxide coating and (3) the formation step of cerium-containing platinum coating. Each will be explained below.

[0033]

[0034] The pretreatment steps of the stainless steel substrate of the present invention include: grinding the stainless steel substrate, degreasing, and then etching and activating in an acid solution to obtain the pretreated substrate. The stainless steel substrate can be polished with sandpaper or fine sand. When using sandpaper for sanding, 80-110 mesh sandpaper can be used, preferably 90-100 mesh sandpaper.

[0035] Soak the polished stainless steel substrate with an alkaline degreasing agent to remove oily substances on the surface. The soaking temperature can be controlled at 30 to 45°C, preferably 35 to 40°C. The immersion time...

specific Embodiment approach

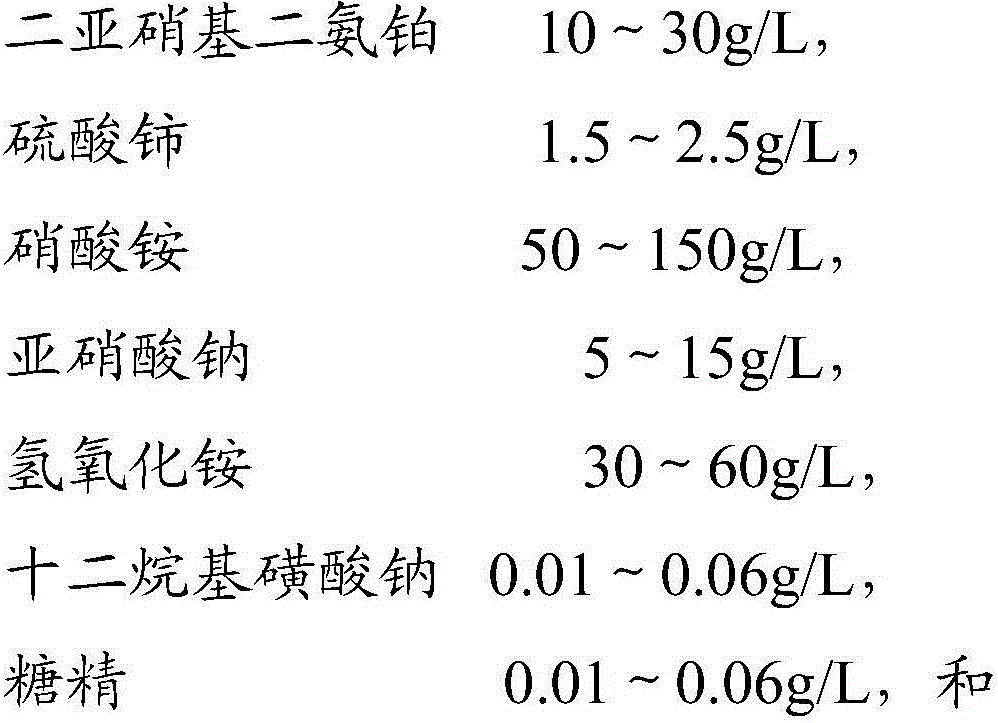

[0046] According to a specific embodiment of the present invention, the electroplating solution includes the following components:

[0047]

[0048]

Embodiment approach

[0049] According to another specific embodiment of the present invention, the electroplating solution is composed of the following components:

[0050]

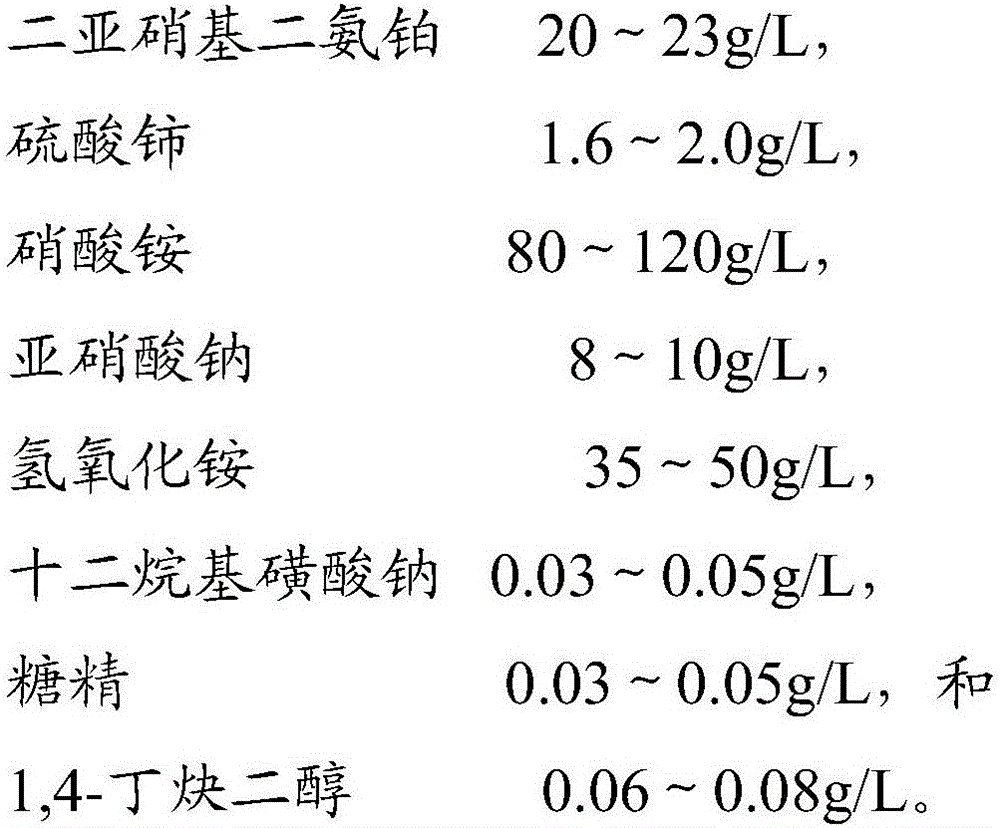

[0051] According to a preferred embodiment of the present invention, the electroplating solution includes the following components:

[0052]

[0053] According to another preferred embodiment of the present invention, the electroplating solution is composed of the above-mentioned components.

[0054] According to a further preferred embodiment of the present invention, the electroplating solution includes the following components:

[0055]

[0056]

[0057] According to another further preferred embodiment of the present invention, the electroplating solution is composed of the aforementioned components.

[0058] The steps of forming the cerium-containing platinum plating layer of the present invention can be performed in conventional electroplating equipment in the art, and will not be repeated here. In the step of forming the cerium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com