A kind of preparation method of conductive adsorption resin

A technology of adsorption resin and carbon nanotubes, which is applied in the direction of chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., to achieve the effect of simple preparation method, good effect, and improved hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

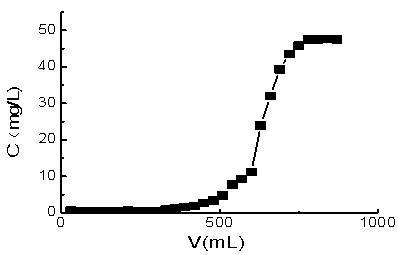

Image

Examples

example 1

[0027] a) Configuration of oil phase

[0028] Place 0.105 g of carbon nanotubes in 15 g of toluene for ultrasonic dispersion for 30 min, add 15 g of reactant composed of styrene and divinylbenzene after cooling, ultrasonically disperse for 10 min, add 0.17 g of dibenzoyl peroxide, stir and dissolve use;

[0029] b) Preparation of conductive adsorption resin

[0030] Add 90 g of an aqueous solution containing 1% polyvinyl alcohol and 5% sodium chloride to a three-necked flask, stir and insulate in an oil bath at 45 °C, add styrene, divinylbenzene, toluene, carbon nanotubes and diphenyl peroxide The oil phase composed of acyl, adjust the stirring speed until the size of the oil droplets is suitable, slowly raise the temperature to 80 °C for 4 h, and continue to slowly raise the temperature to 90 °C for 3.5 h. After the polymerization is completed, filter out the resin, rinse it with hot water for several times, replace it with ethanol and dry it, extract it with petroleum ethe...

example 2

[0033] a) Modification of carbon nanotubes

[0034] Add 60mL of water and 0.025g of sodium ethoxide into a beaker, stir to dissolve, add 0.20g of carbon nanotubes for ultrasonic dispersion for 10 min, then add 0.7 g of p-chloromethylstyrene and continue ultrasonication for 20 min, then stir in a water bath at 40 °C for 2 h , use a vacuum filter device to filter and wash off the residual reagent with ethanol, replace with distilled water to wash off the ethanol, take it out and dry it in an oven at 70 °C for later use;

[0035] b) Equipped with oil phase

[0036] Add 0.20 g of modified carbon nanotubes into the beaker, add 2.5 g of toluene for ultrasonic dispersion for 20 min, add 5 g of reactants composed of styrene and divinylbenzene after cooling, and add the initiator azo After diisobutyronitrile is stirred and dissolved, the oil phase is obtained;

[0037] c) Preparation of conductive adsorption resin

[0038] In a 250 mL three-neck flask, add an aqueous solution contai...

example 3

[0041] a) Modification of carbon nanotubes

[0042] Add 160 mL of water and 0.10 g of sodium ethoxide into the beaker, stir to dissolve, add 0.50 g of carbon nanotubes for ultrasonic dispersion for 10 min, then add 1.0 g of p-chloromethylstyrene and continue ultrasonication for 20 min, then stir in a water bath at 40 °C for 2 h , use a vacuum filter device to filter and wash off the residual reagent with ethanol, replace with distilled water to wash off the ethanol, take it out and dry it in an oven at 70 °C for later use;

[0043] b) Equipped with oil phase

[0044] Add 0.50 g of modified carbon nanotubes into the beaker, add 20 g of toluene for ultrasonic dispersion for 20 min, add 10 g of reactants composed of styrene and divinylbenzene after cooling, and add the initiator azo After diisobutyronitrile is stirred and dissolved, the oil phase is obtained;

[0045] c) Preparation of conductive adsorption resin

[0046]In a 250 mL three-neck flask, add an aqueous solution co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com