A method for preparing single-layer tungsten diselenide nanobelts based on spatial confinement strategy

A tungsten diselenide and nanobelt technology, applied in chemical instruments and methods, nanotechnology, selenium/tellurium compounds, etc., can solve the problems of inability to realize industrial application, reduce sample quality, affect performance, etc., and achieve high-quality batch preparation , good reproducibility, low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

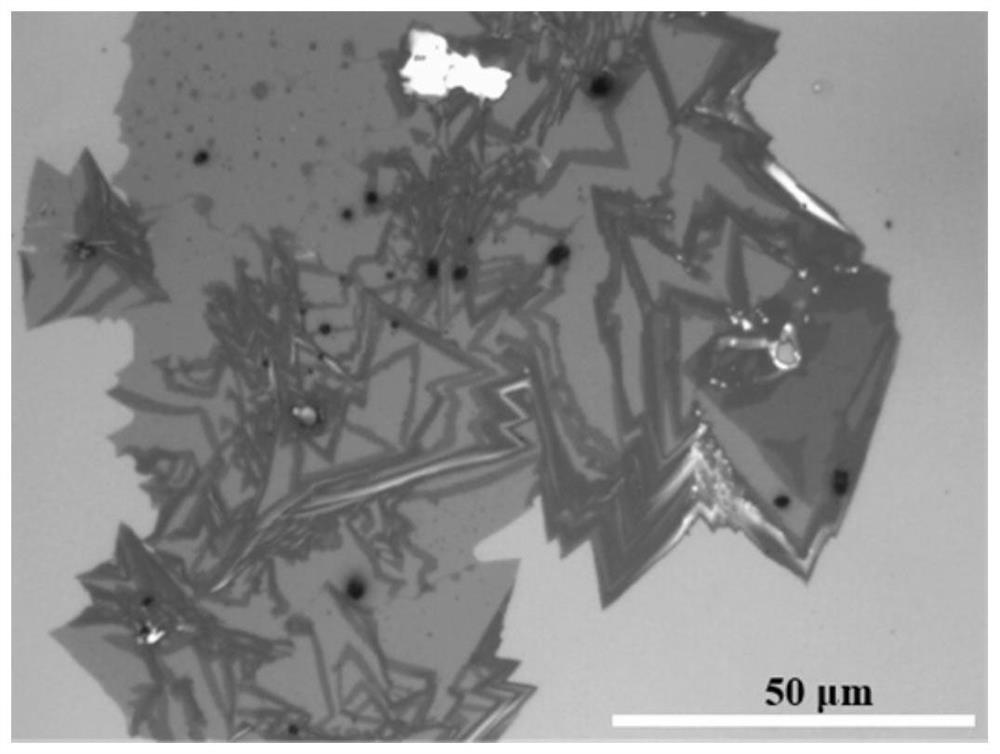

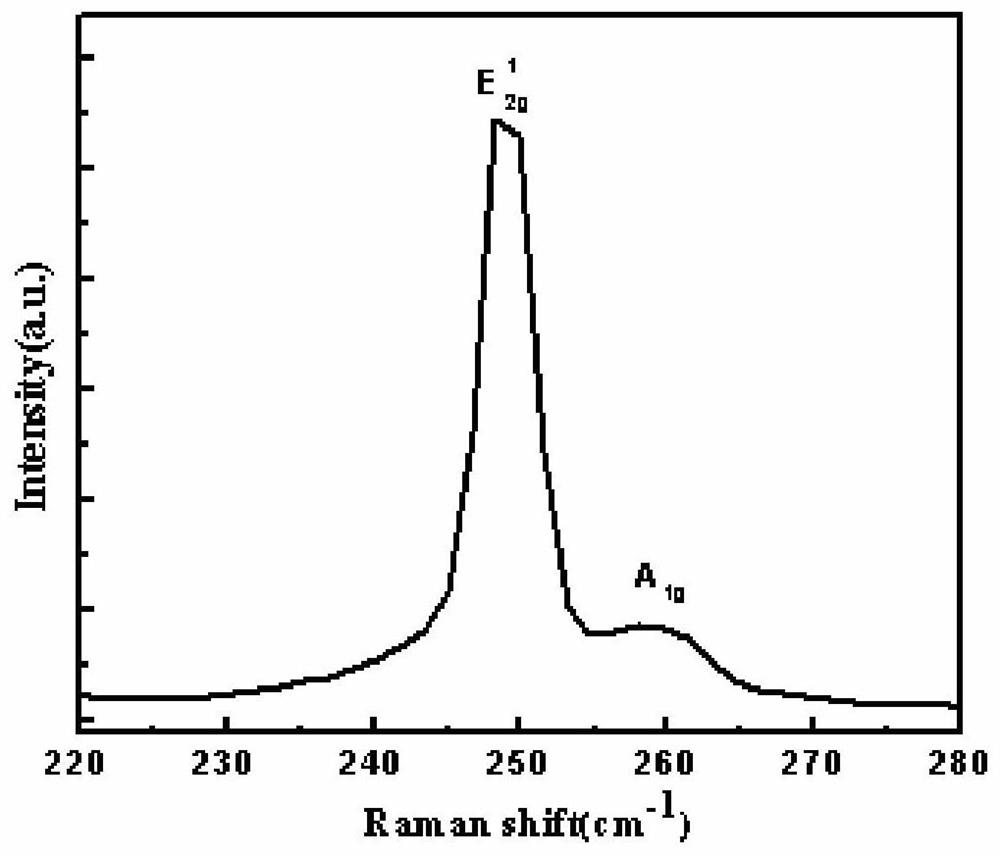

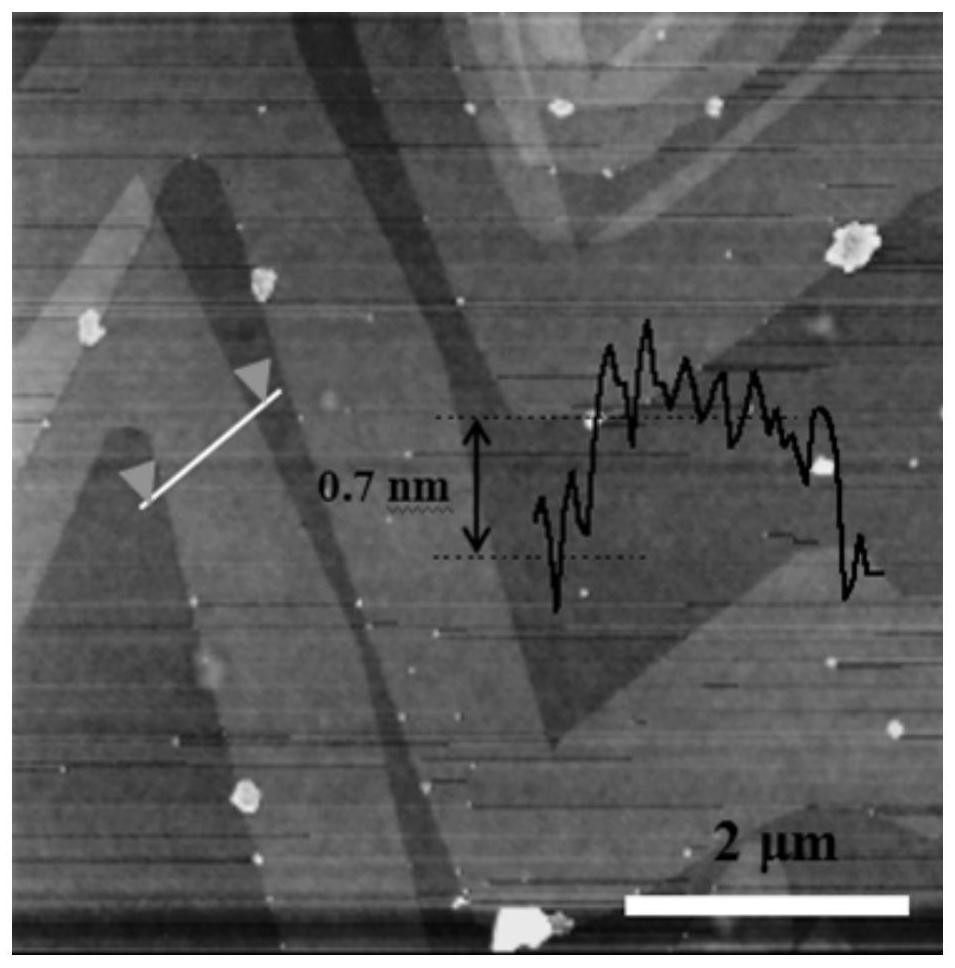

Embodiment 1

[0035] The purchased silicon dioxide wafers were washed in ethanol and deionized water in turn, and then dried with nitrogen gas. Place the cleaned silicon dioxide sheet in the heating center of the high-temperature tube furnace, and put selenium powder (near the upstream of the nozzle), tungsten trioxide and silicon dioxide sheet ( downstream heating center), (tungsten trioxide powder is sprinkled between two silicon wafers). The masses of the selenium powder and the tungsten trioxide are 430-500 mg and 15-30 mg respectively, and the distance between the selenium powder and the tungsten trioxide is 24 cm. Then, argon gas (500 sccm) was introduced into the reaction chamber to clean the reaction chamber, and the residual air in the chamber was discharged, and the cleaning time was 30 minutes. Subsequently, the temperature program is raised to control the temperature of the tube furnace to be 800-850° C., so that the temperatures of selenium powder and tungsten trioxide powder ...

Embodiment 2~36

[0038]The silicon dioxide-silicon dioxide substrate in embodiment 1 is used sapphire-sapphire substrate, graphene-graphene substrate, mica-mica substrate, glass-glass substrate, single crystal silicon-single crystal silicon silicon substrate, and these substrates Any two combinations can be replaced, and other preparation conditions remain unchanged, and tungsten diselenide nanobelts with better quality can also be obtained.

Embodiment 37~72

[0040] By vertically stacking the substrates of various two-piece combinations in Examples 2-36, and other preparation conditions remain unchanged, tungsten diselenide nanoribbons with good quality can also be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com