Matte water-based transfer coating and preparation method thereof

A transfer coating, water-based technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of inability to meet long-term stable storage requirements, large consumption of aluminum foil, non-compliance, etc., and achieve excellent storage stability and coating flow flat effect effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

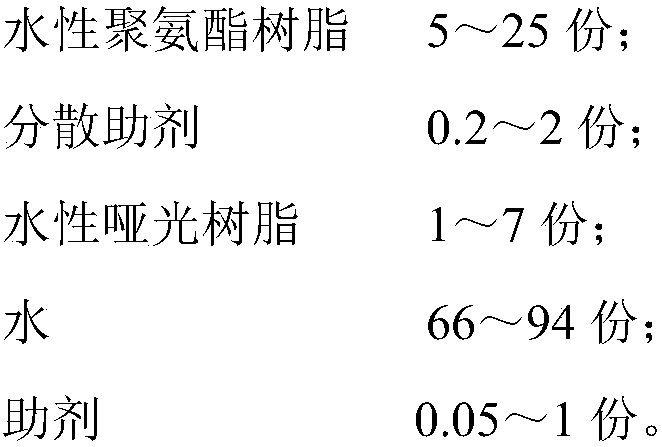

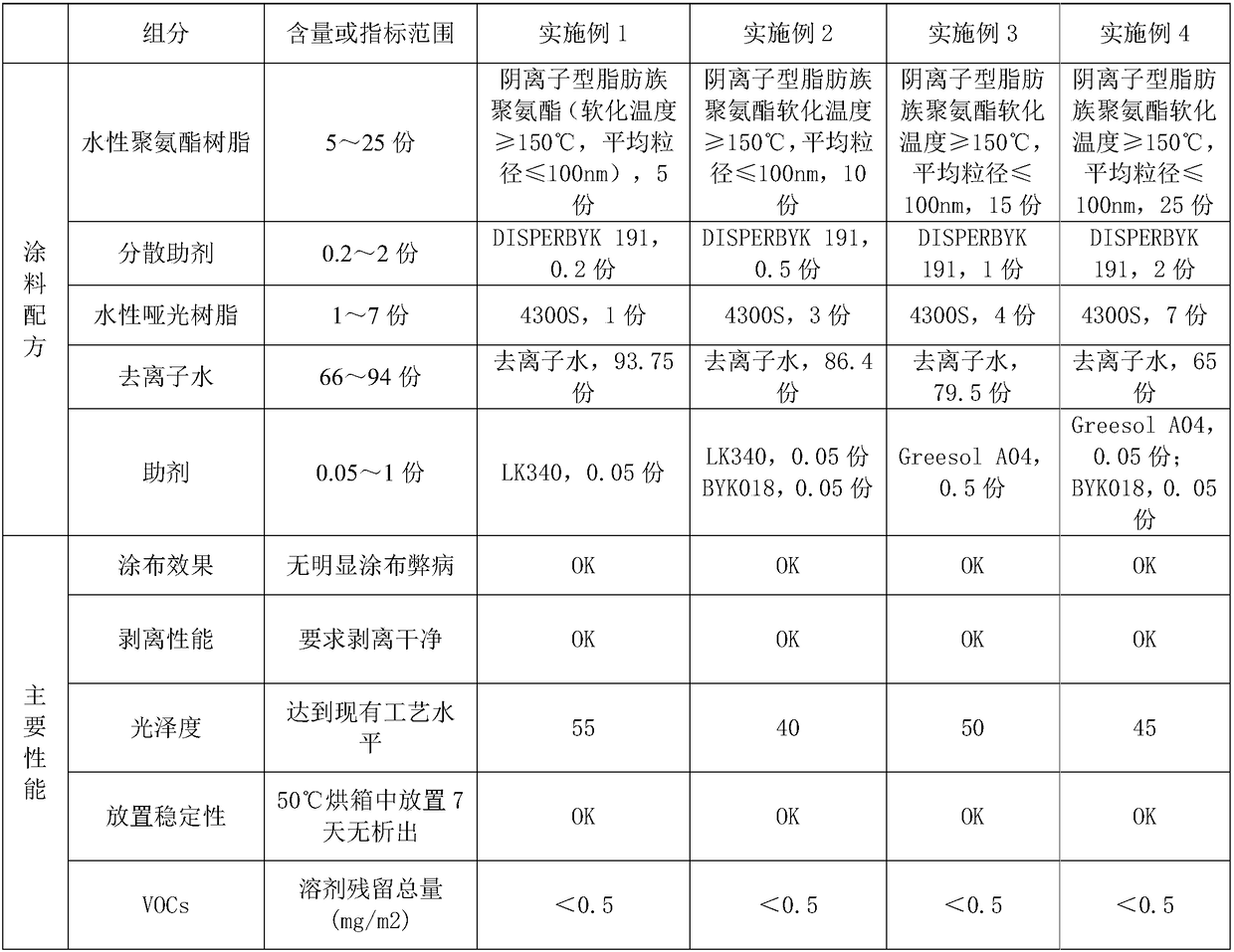

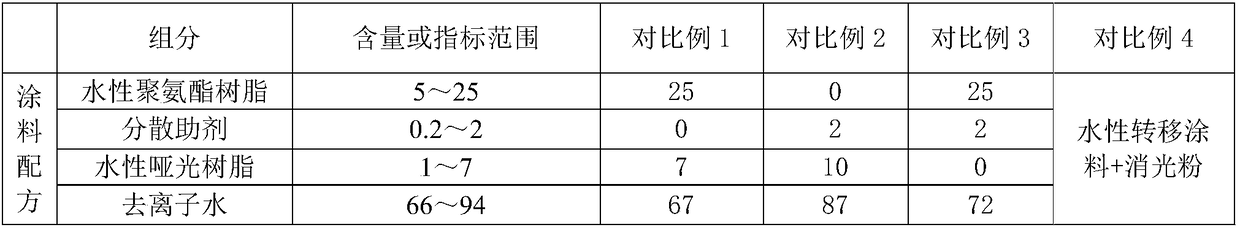

[0036] Embodiment 1-4 provides a kind of matte water-based transfer coating and preparation method thereof respectively;

[0037] The specific components and contents are shown in Table 1;

[0038] The preparation method is as follows: mix the water-based polyurethane resin and the dispersing aid uniformly to obtain the mixture A; add the water-based matte resin and water to the mixture A and mix uniformly to obtain the mixture B; then add the auxiliary agent to the mixture B and mix uniformly After filtering, the matte water-based transfer coating is obtained;

[0039] Wherein, the uniform mixing method is stirring, and the stirring time is 20 minutes; the water-based matte resin and water are added under stirring conditions, and the stirring speed is 500 rpm; the filter adopts a filter screen with a size of 100 mesh; The preparation method is completed in a reaction kettle; the preparation method also includes the step of packaging the obtained matte water-based transfer co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com