A device for inverting molds for paper raw pulp

A paper and mold technology, which is applied in the field of recycle paper to prepare original pulp inversion molding, can solve the problems of limited non-renewable resources, poor paper quality, and high maintenance costs, and achieve the effects of saving device construction costs, powerful functions, and time saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

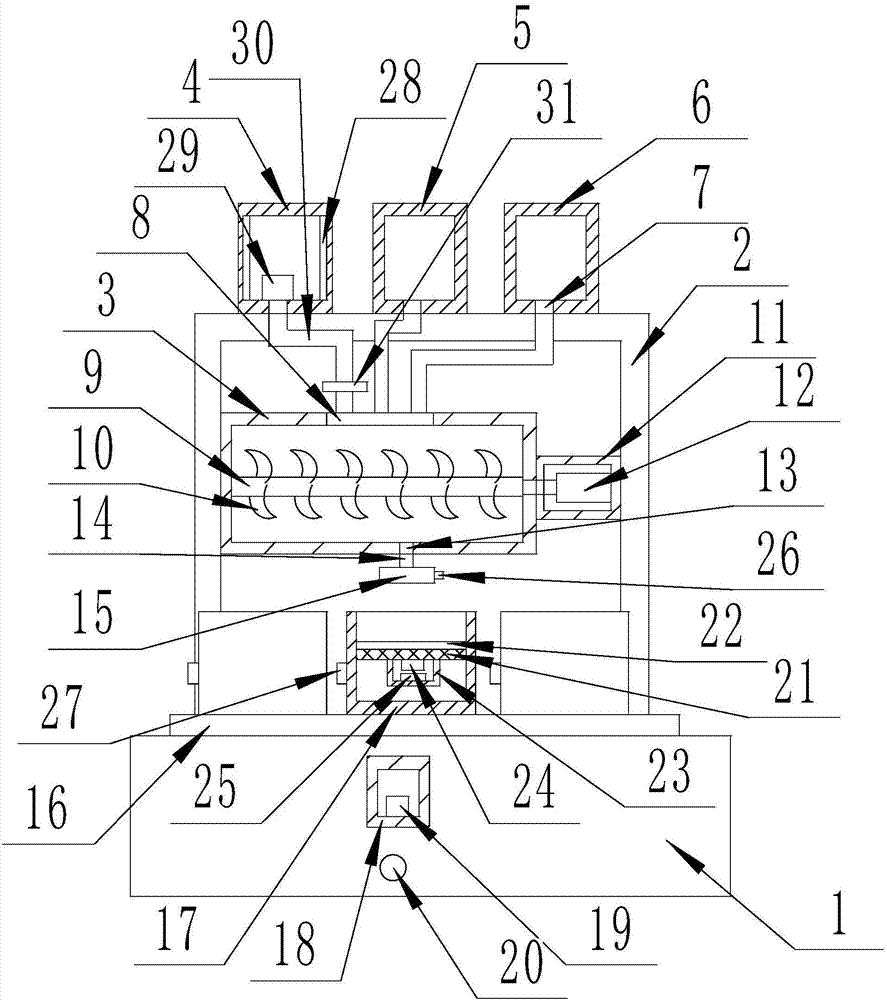

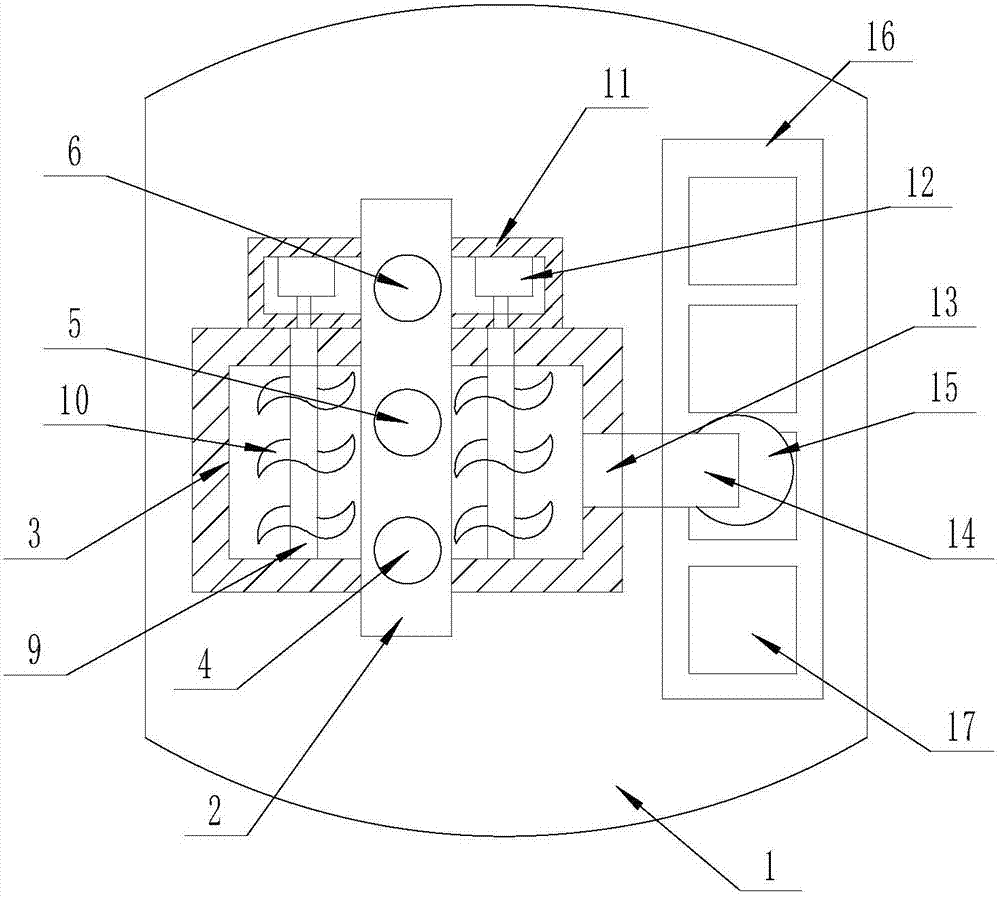

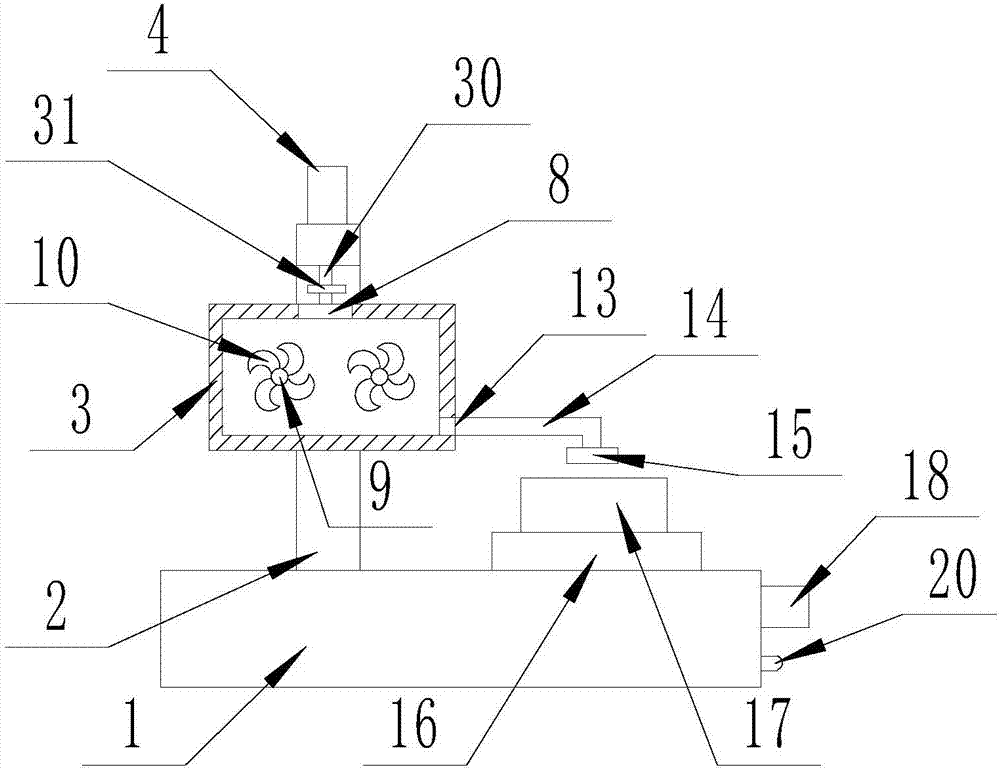

[0015] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-3 As shown, a device for inverting and shaping paper raw pulp, including an operating table (1), the upper surface of the operating table (1) is provided with a pulverizing and stirring raw pulp preparation mechanism, and the pulverizing and stirring raw pulp preparation mechanism is arranged on a set The gantry (2) on the upper surface of the console (1), the blending box (3) arranged on the gantry (2), the water storage bucket (4) arranged on the upper surface of the gantry (2), The material storage tank (5) and the bleaching tank (6), the outlet (7) processed on the lower surface of the water storage tank (4), the material storage tank (5) and the bleaching tank (6), the processing in the blending box (3 ) at the center of the upper surface, a set of rotating rods (9) arranged in the blending box (3), rotating blades (10) arranged on a group of rotating rods (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com