Movable waste warehouse with classification function

A mobile, waste technology, applied in small buildings, buildings, building structures, etc., can solve the problems of inability to move at any time, low space utilization, burning of waste warehouses, etc., to increase space utilization, simple and reasonable structure , good fire protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

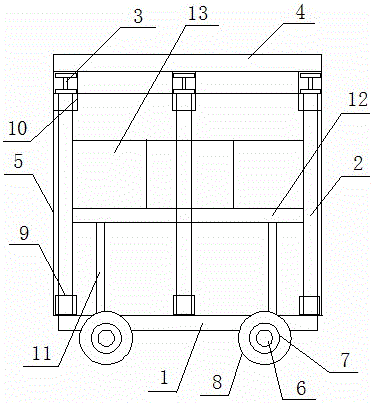

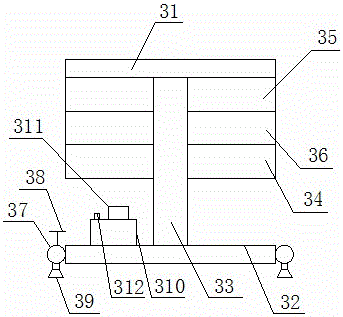

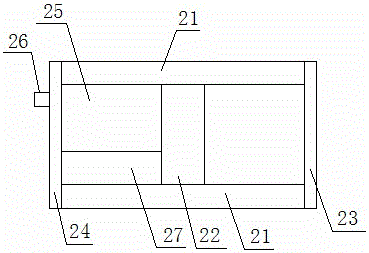

[0018] Such as figure 1 and figure 2 The shown mobile waste sorting warehouse includes a base plate 1, upright columns 2, beams 3, roof panels 4 and side wall panels 5, the lower surface of the base plate 1 is connected to a set of parallel supporting horizontal shafts 6, and each supporting horizontal shaft The two ends of 6 are respectively connected with bearings 7, and the bearings 7 are covered with traveling wheels 8; the upper surface of the base plate 1 is provided with a plurality of column seats 9, and the bottom ends of the columns 2 are installed on the column seats 9 and fixed with bolts; The joint 10 is vertically connected and fixed with bolts, and the beam 3 is horizontally connected with the double-way joint 10 and fixed with bolts; the roof plate 4 is installed on the beam 3, and the side wall plate 5 is installed on the column 2; the bottom plate 1 is provided with a lifting device 11, The lifting device 11 is provided with a lifting plate 12, and the lift...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com