Combined heat insulation type steel-structured ceiling

A combined, profiled steel technology, applied in the direction of roof insulation, roof, roof ventilation, etc., can solve the problems of heat insulation, poor heat dissipation, and not easy to disperse.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

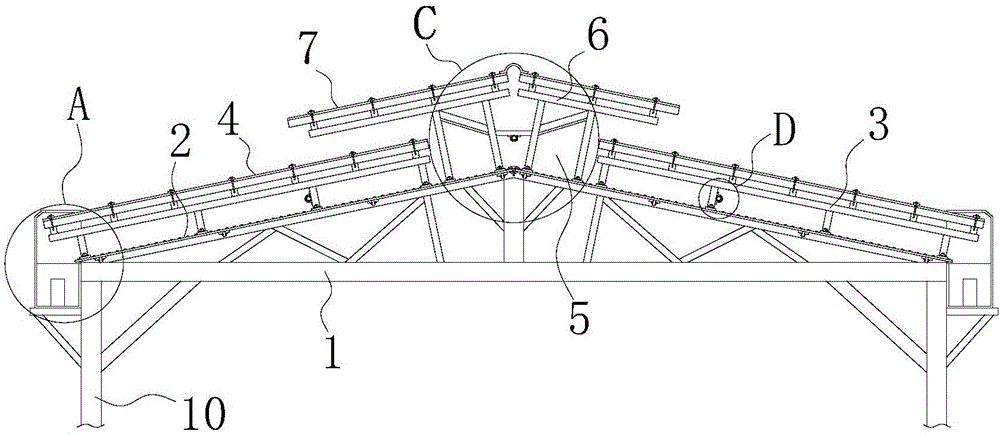

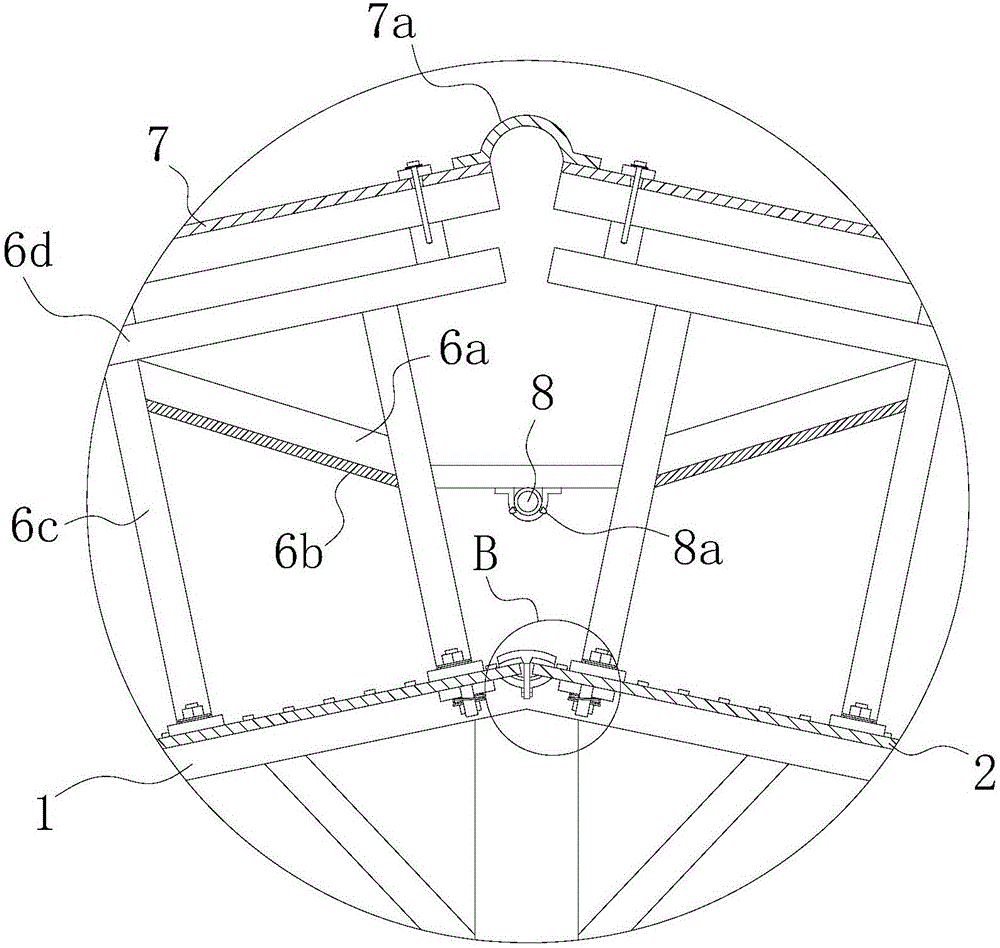

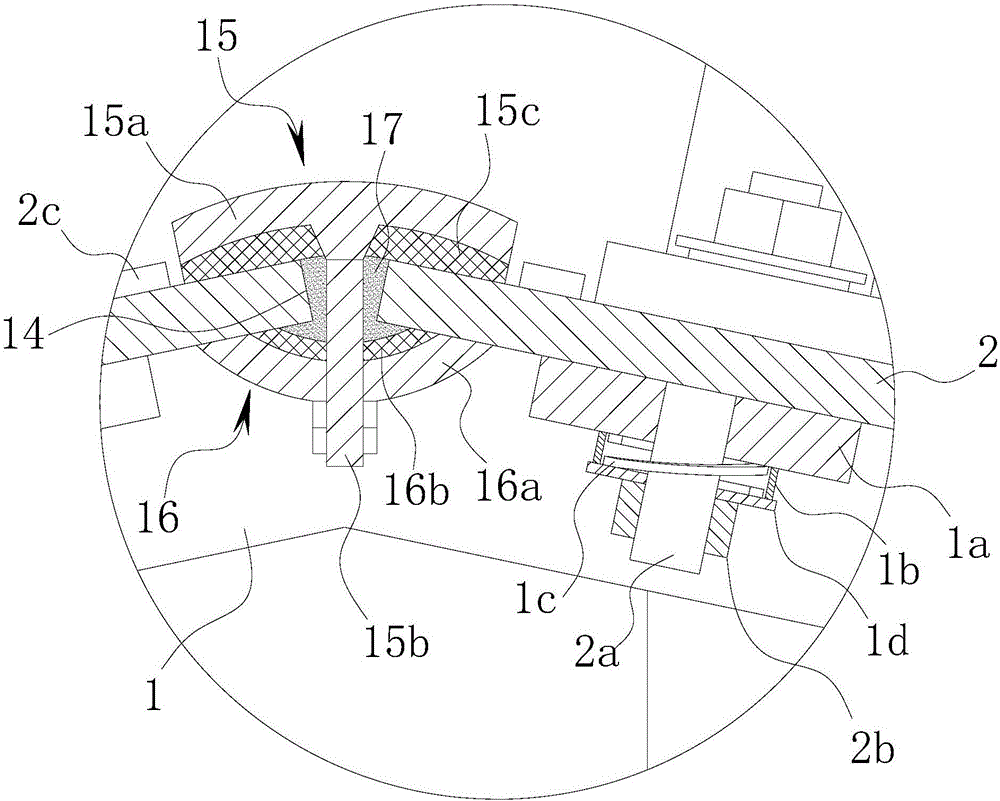

[0022] refer to Figure 1 to Figure 5 As shown, a combined heat-insulating steel structure ceiling of the present invention includes a bracket 1 with a triangular cross-section. Some heat dissipation columns 2c, the height of each heat dissipation column 2c is 5-10mm, the heat dissipation columns not only play the role of increasing the heat dissipation area, but also play the role of strengthening the strength of the rain-proof layer. In this embodiment, the rain-proof layer 2 is stainless steel Material, the thickness of the rain layer is 5-10mm. Specifically, a number of installation bosses 1a are distributed on the bracket 1, and the upper surface of the installation boss 1a is on the same plane as the upper end surface of the bracket 1; The positioning stud 2a is provided with a through hole compatible with the positioning stud 2a on the mounting boss 1a, and the lower end surface of the mounting boss 1a on the periphery of the positioning stud 2a is provided with an acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com