Bridge-cutoff aluminum alloy section heat insulation strip

A technology for aluminum alloy profiles and thermal insulation strips, applied in the field of aluminum alloy profiles, can solve the problems of high mold cost, unsightly C-shaped thermal insulation strips, mechanical properties, deformation, etc., and achieve the effect of reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

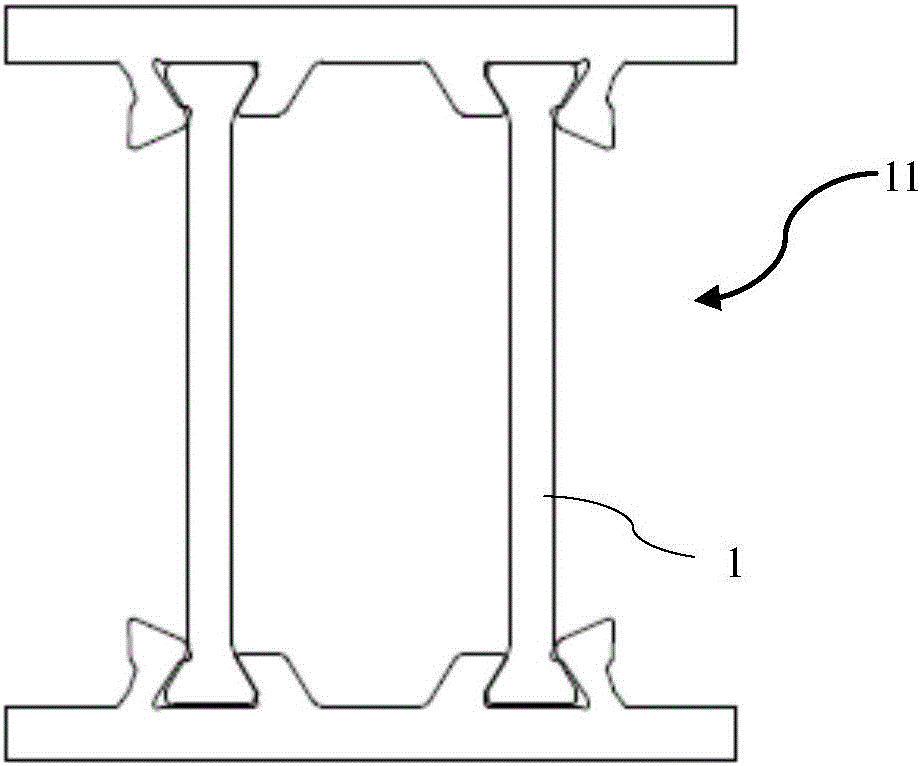

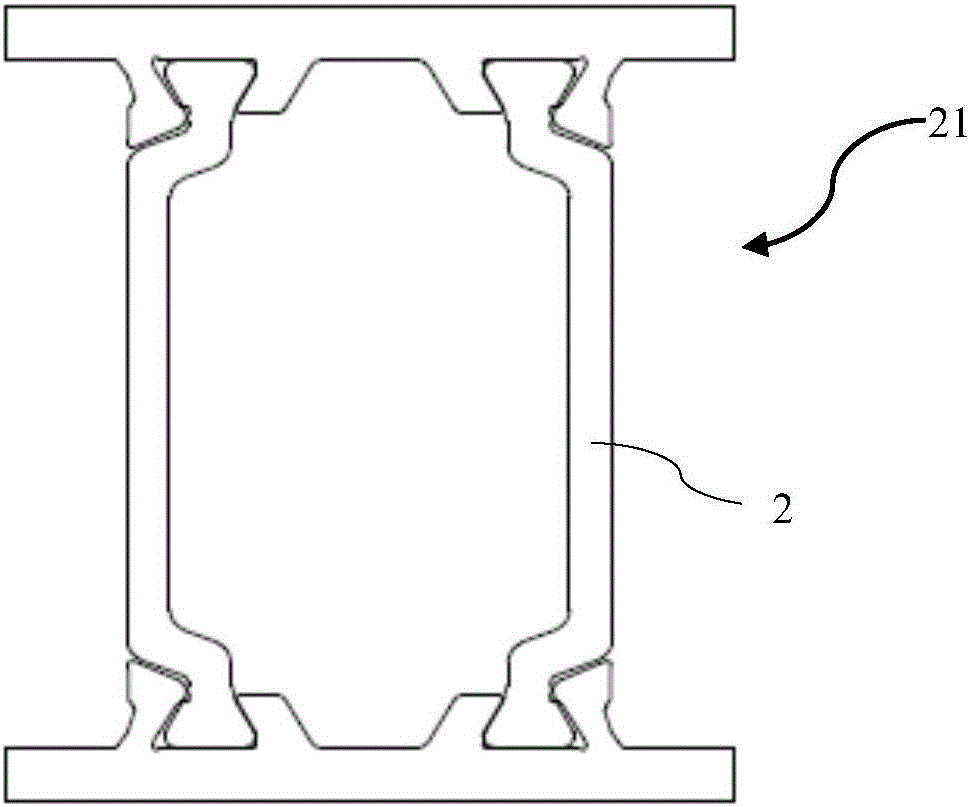

[0023] Please refer to Figure 4 Shown is the first specific implementation of the heat insulation strip for a broken bridge aluminum alloy profile of the present invention. A bridge-broken aluminum alloy profile heat insulation strip, comprising: a first heat insulation piece 4 with connecting edges 41 formed at both ends, and a second heat insulation piece 5 buckled longitudinally. Both the first heat insulator 4 and the second heat insulator 5 have a sheet structure and form a cavity 55 . The heat-insulating bar of aluminum alloy profiles for broken bridges is arranged between two parallel aluminum alloy profiles 7 . Ribs 72 and ribs 73 are formed inside the aluminum alloy profile to form a receiving groove 71 for accommodating the connecting edge 41 of the first heat insulating element 4 through the ribs 72 and the ribs 73 . The first heat insulator 4 can be made of polyamide 66, and plays the role of supporting and connecting two aluminum alloy profiles 7 to form a brok...

Embodiment 2

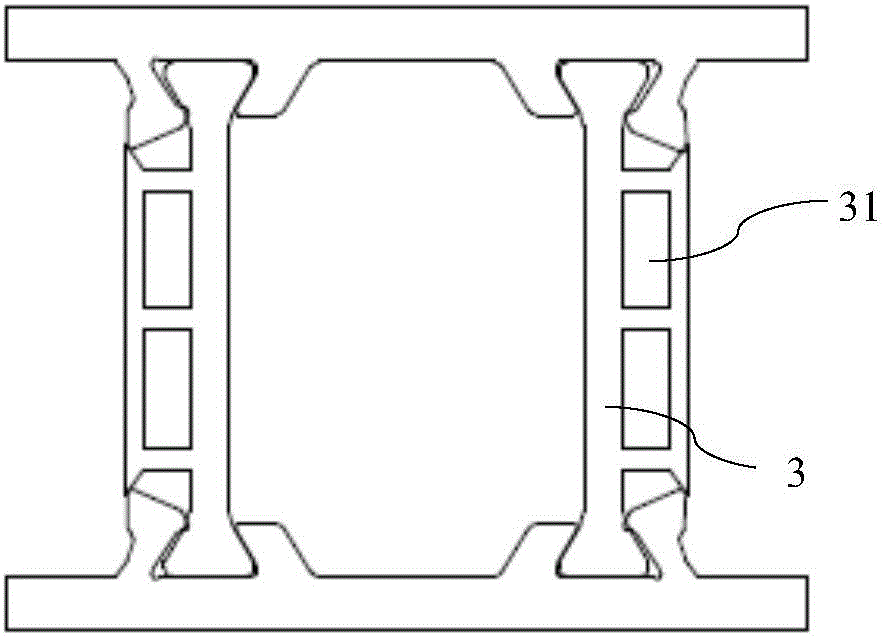

[0027] Please refer to Figure 5 and Image 6 Shown is the second specific embodiment of a heat insulation strip for a broken bridge aluminum alloy profile of the present invention. The main difference between this embodiment and Embodiment 1 is that, in this embodiment, the end of the constriction portion 53 is further provided with an abutment portion 533, and the abutment portion 533 is formed with an abutment surface 534 extending longitudinally. The included angle between the abutting surface 534 and the shielding surface is greater than or equal to 90 degrees, thereby realizing a better sealing effect on the outer lower edge of the raised rib 72 . A constricted part 53 is formed at the end of the shielding part 52, and the constricted part 53 is formed with a shielding surface 531 facing the side part of the broken bridge aluminum alloy profile. The shielding surface 531 defines a plurality of grooves 532 arranged longitudinally. Meanwhile, the rib 72 is formed with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com