Falling preventing device of door rolling machine

A door rolling machine and anti-drop technology, which is applied to door/window protection devices, windows/doors, building components, etc., can solve the problems of weak impact resistance, high hardness of gears, and fragile steel balls, so as to reduce the impact strength , enhance the strength, avoid the effect of breaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

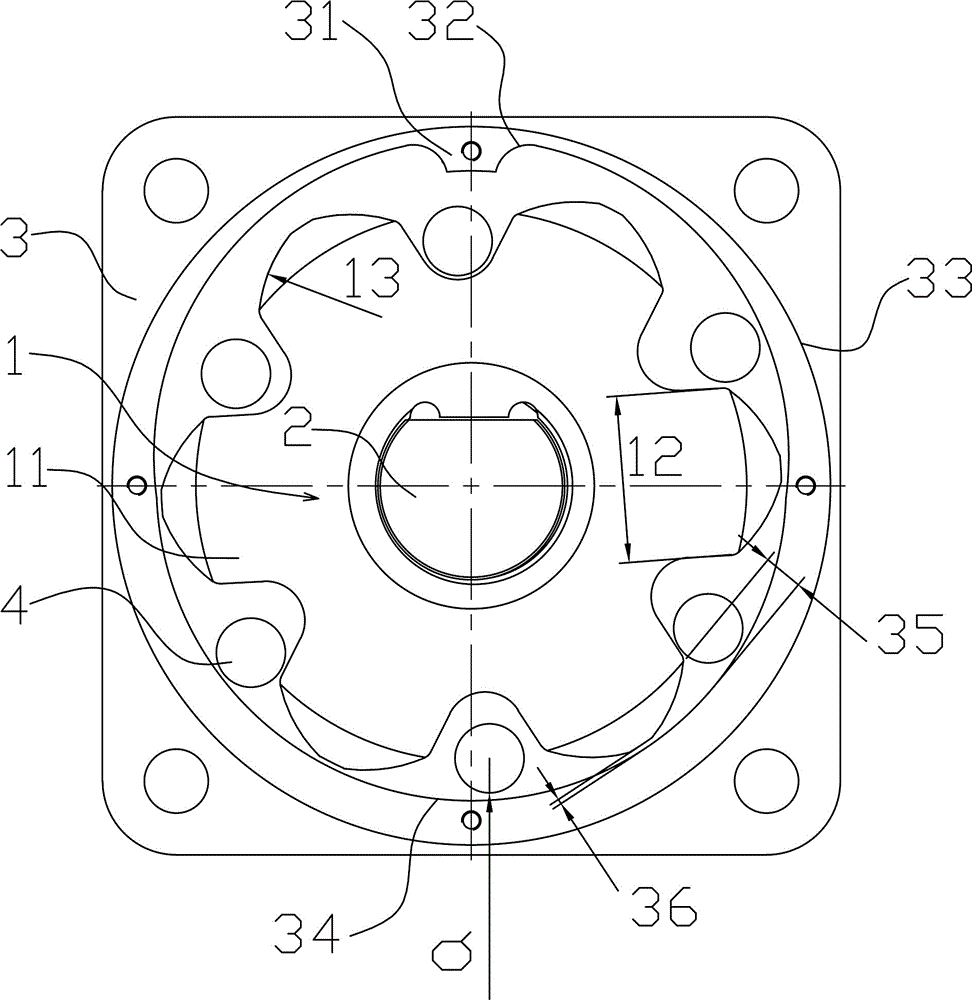

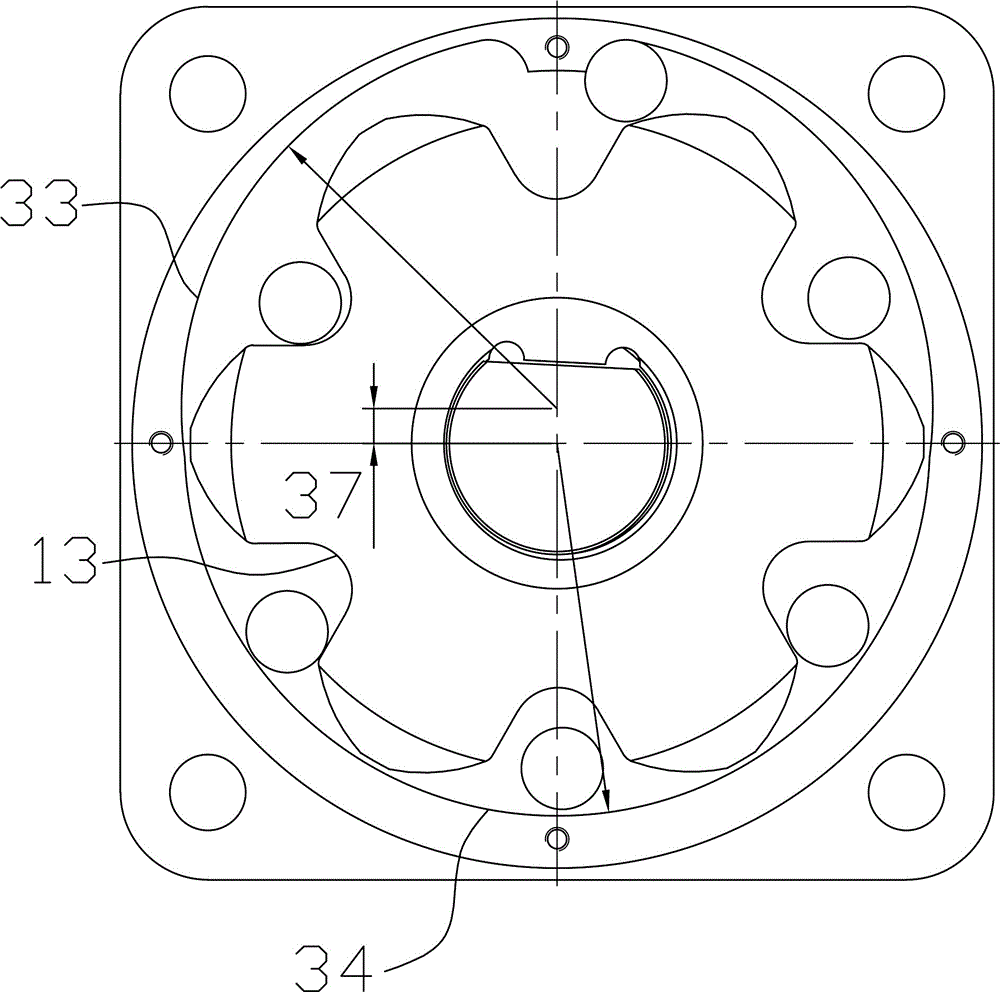

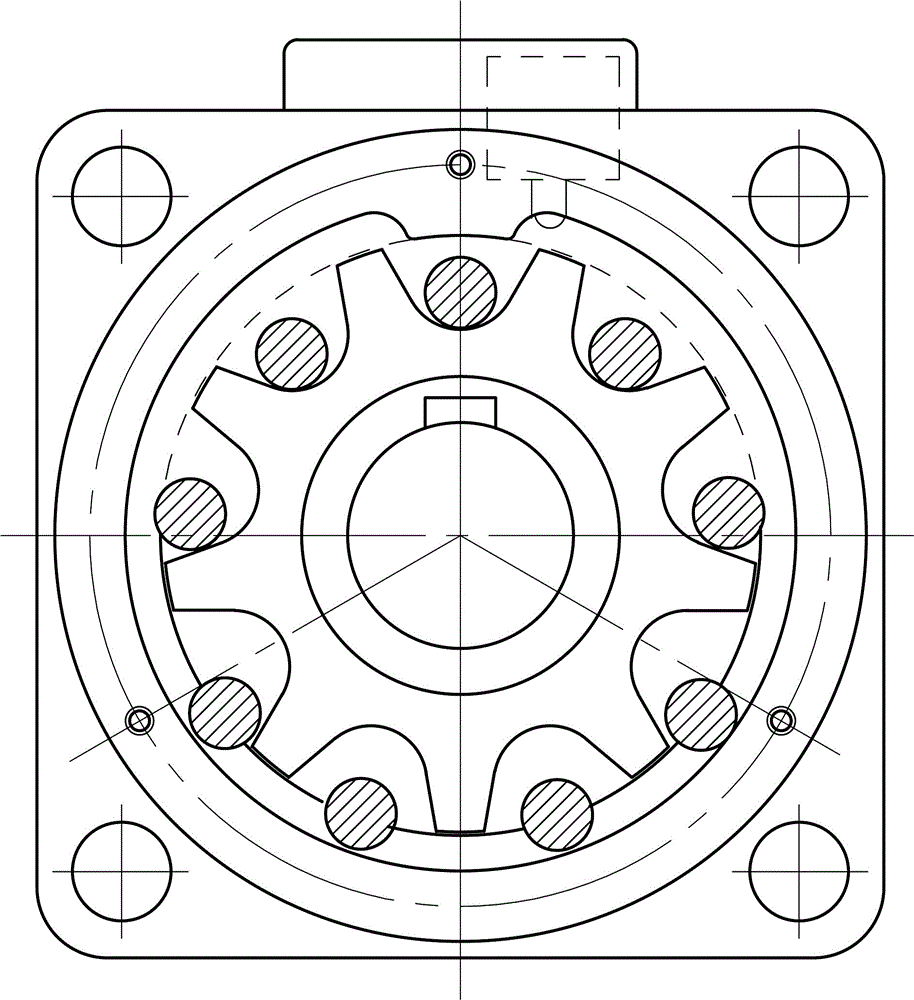

[0024] Such as Figure 1~2 Among them, an anti-falling device for a rolling door machine, including a base 3, a concave cavity is provided on the base 3, a self-locking gear 1 is installed in the cavity, and the self-locking gear 1 is fixedly connected to a transmission shaft 2;

[0025] The teeth 11 of the self-locking gear 1 are provided with movable steel balls 4 or steel columns. The inner wall of the cavity is a fairway, and the top of the fairway is provided with a self-locking boss 31, and both sides of the self-locking boss 31 are provided with bosses. The bottom arc 32, the radius of the boss bottom arc 32 is the same as the radius of the steel ball 4 or the steel column, the top of the tooth 11 is arc-shaped, and the fairway is composed of the fairway side arcs 33 on both sides and the fairway bottom arc 34 at the bottom. The radius of the bottom arc 34 of the fairway is smaller than the radius of the side arc 33 of the fairway, so that when the tooth 11 approaches t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com