Actuating device

A technology for actuating equipment and equipment, which is applied in the direction of mechanical equipment, engine components, combustion engines, etc., can solve expensive and technically complex problems, and achieve the effect of eliminating complicated and expensive welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

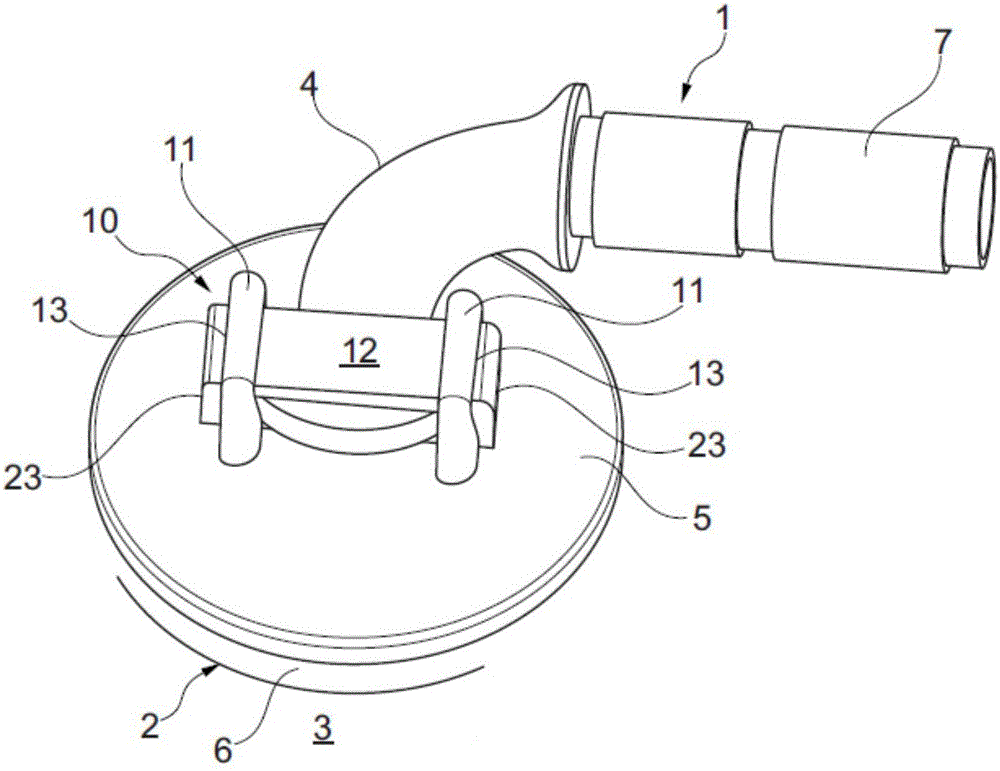

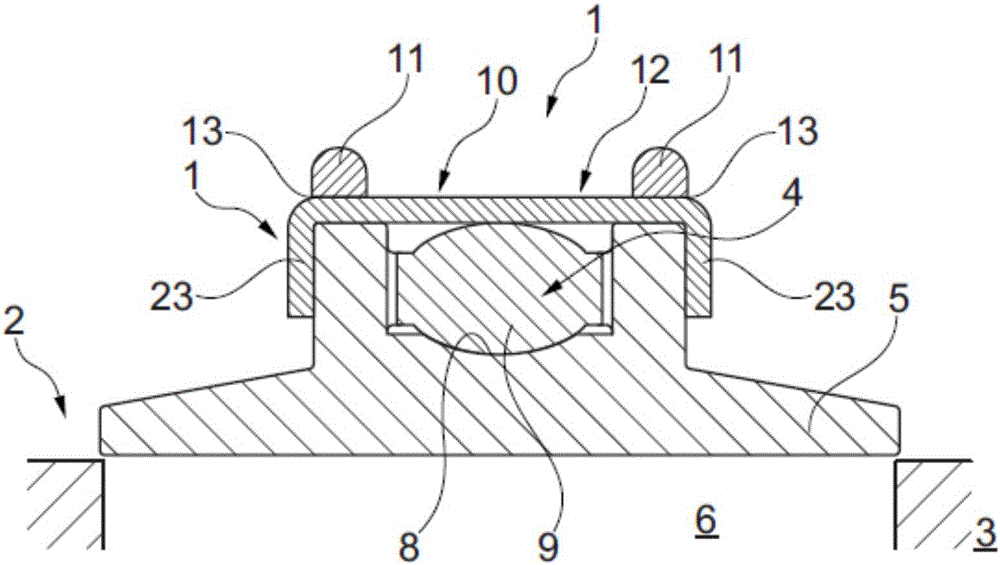

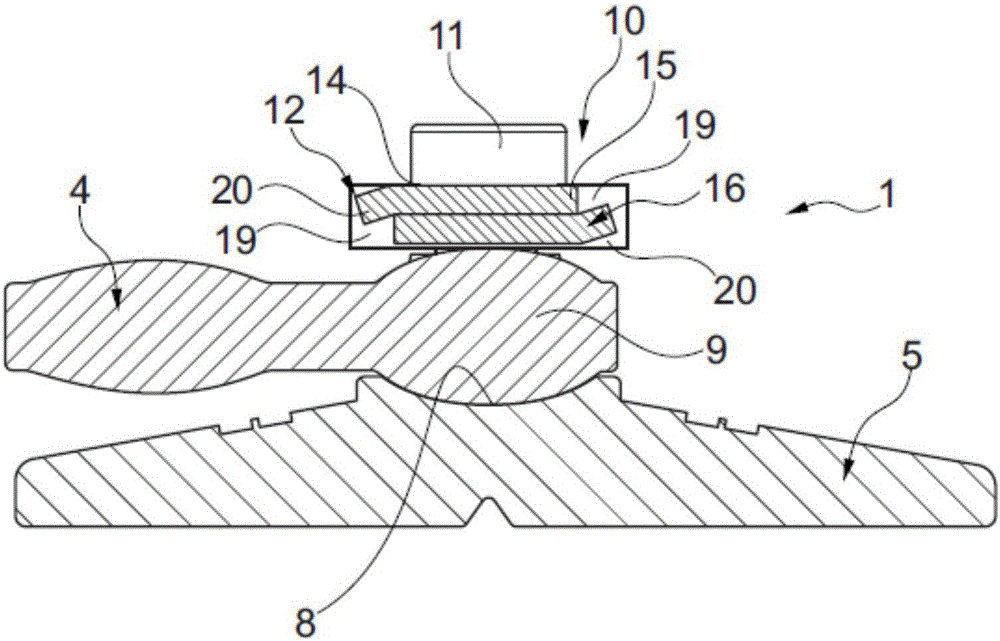

[0025] according to Figure 1 to Figure 3 as well as Image 6 with Figure 7 , according to the invention for an actuating device 1 for a valve 2 , in particular for a wastegate valve for an exhaust gas turbocharger 3 , having a lever arm 4 and a plate connected thereto for closing the opening 6 of the valve 2 5. Here the lever arm 4 is attached to the spindle 7 of the actuating device 1 . The plate 5 has a concave groove 8, while the lever arm 4 has a spherical area 9 formed in a complementary manner with respect to the concave groove 8 of the plate 5, and with which the lever arm engages in the concave shape of the plate 5. in groove 8. Furthermore, a holding device 10 with two holding elements 11 and a connecting element 12 connecting the holding elements 11 is provided on the plate 5, said holding device engaging around the spherical area 9 of the lever arm 4, as a result, fixing the plate 5 on the bar on arm 4.

[0026] In order to be able to configure the component...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap