Electronic semi-active control engine suspension with variable air chamber

A semi-active control, air chamber technology, applied in mechanical equipment, power units, gas shock absorbers, etc., can solve problems such as increasing the loss factor, increasing the rate of change of the dynamic characteristics of the electronic SAC engine suspension, and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

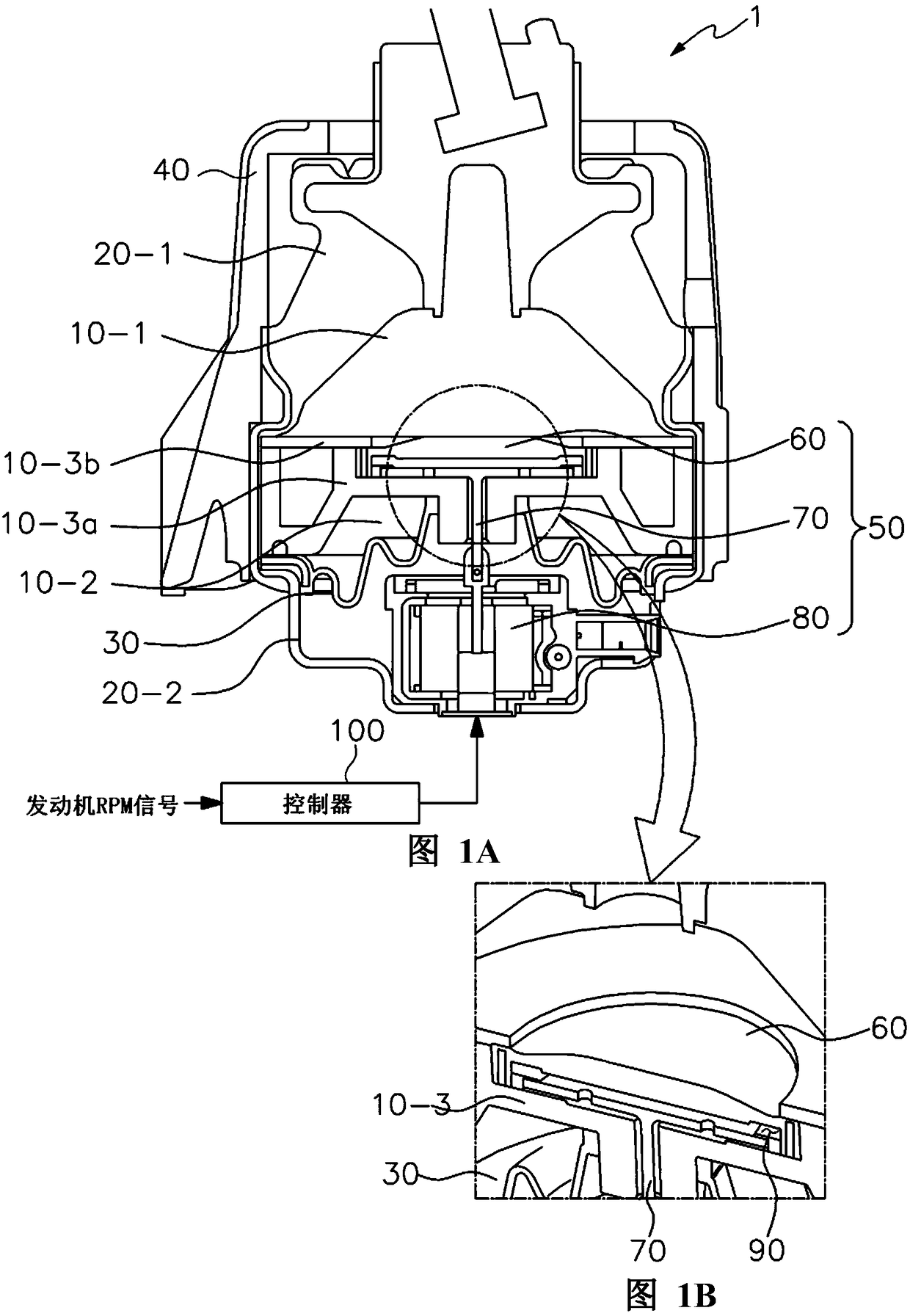

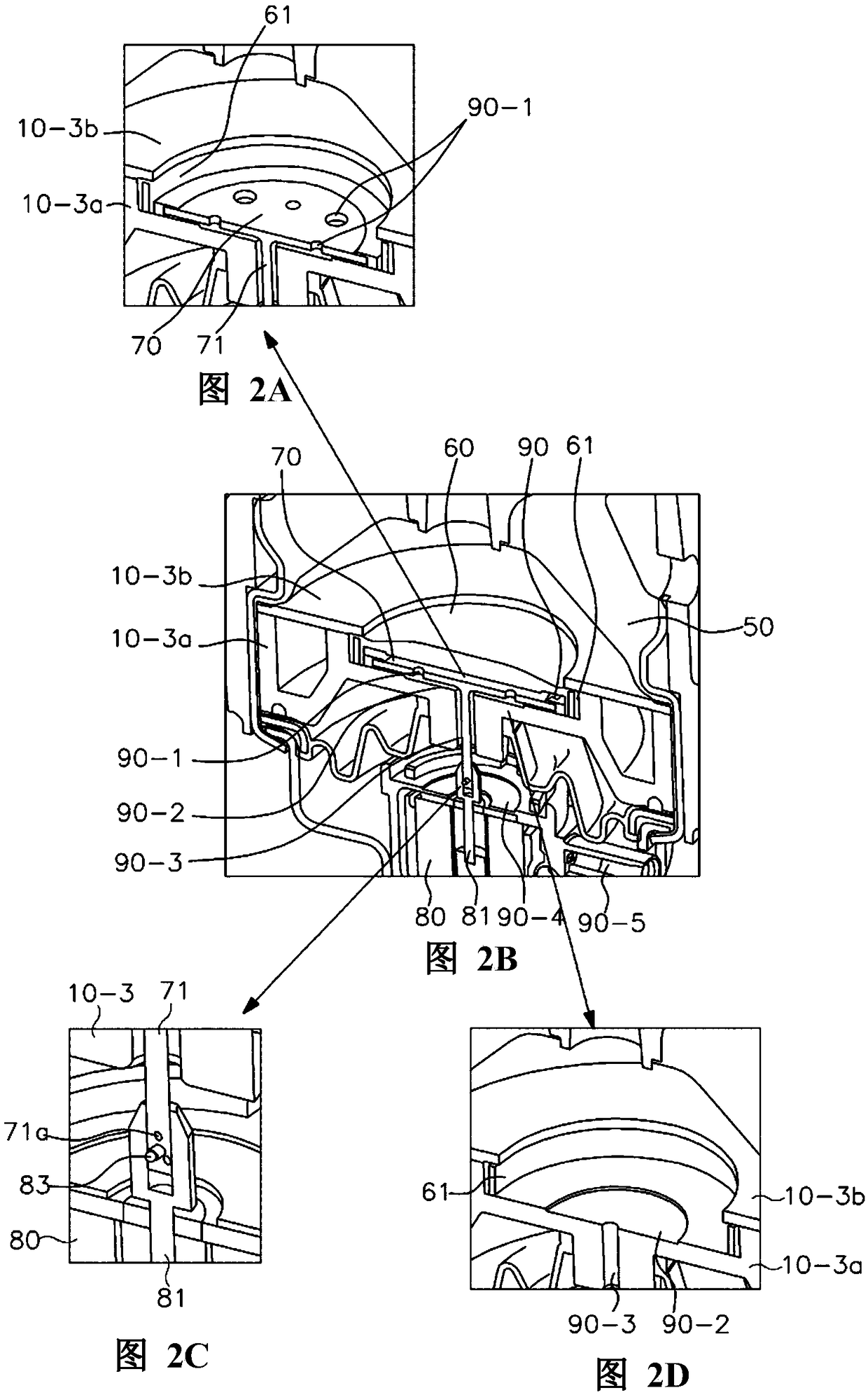

[0027] Figure 1A is a view showing the construction of an electronic SAC engine suspension with a variable air chamber according to the concept of the present invention, and Figure 1B for Figure 1A A partially enlarged view of the part marked with a circle in the middle.

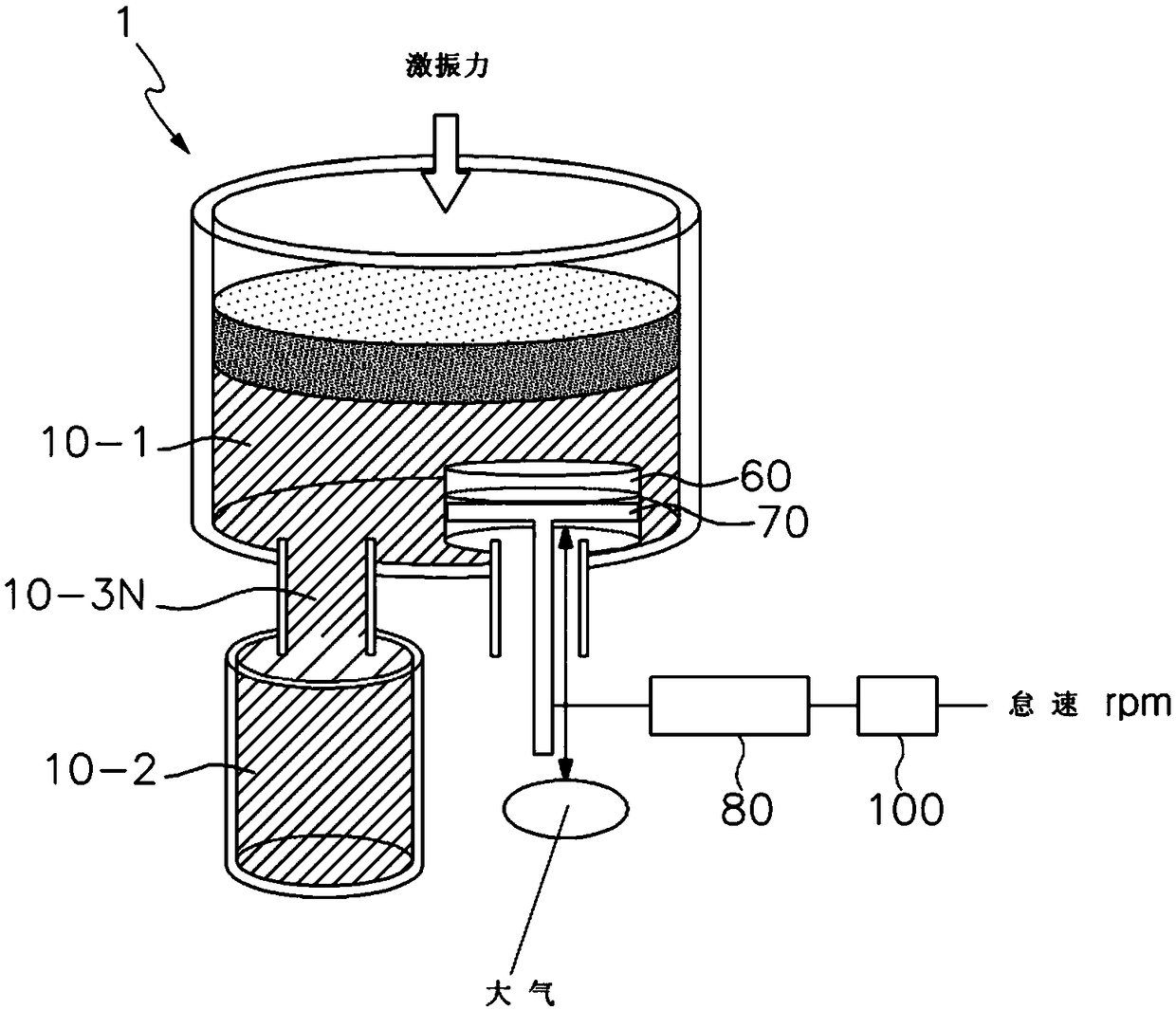

[0028] refer to Figure 1A with Figure 1B , electronic SAC engine suspension 1 includes upper and lower fluid chambers 10-1 and 10-2, channel connection plate 10-3a, channel connection cover 10-3b, upper and lower cores 20-1 and 20-2, main diaphragm 30. Mounting case 40, variable air chamber unit 50 having variable air chamber 90, and controller 100 controlling variable air chamber unit 50 according to engine revolutions per minute (RPM) to form Or remove the variable air chamber 90.

[0029] The upper and lower fluid chambers 10-1 and 10-2, the channel connection plate 10-3a and the channel connection cover 10-3b form a fluid storage part in the electronic SAC engine suspension 1, and form a fluid cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com