Pipeline compensator used for catalytic cracking equipment

A pipeline compensator and catalytic cracking technology, which is applied in the expansion compensation device for pipelines, pipeline protection, mechanical equipment, etc., can solve the problems that cannot completely solve the adverse effects of metal bellows, affect the working performance and service life of compensators, etc. , to achieve the effect of solving adverse effects, prolonging the service life and ensuring reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings and embodiments.

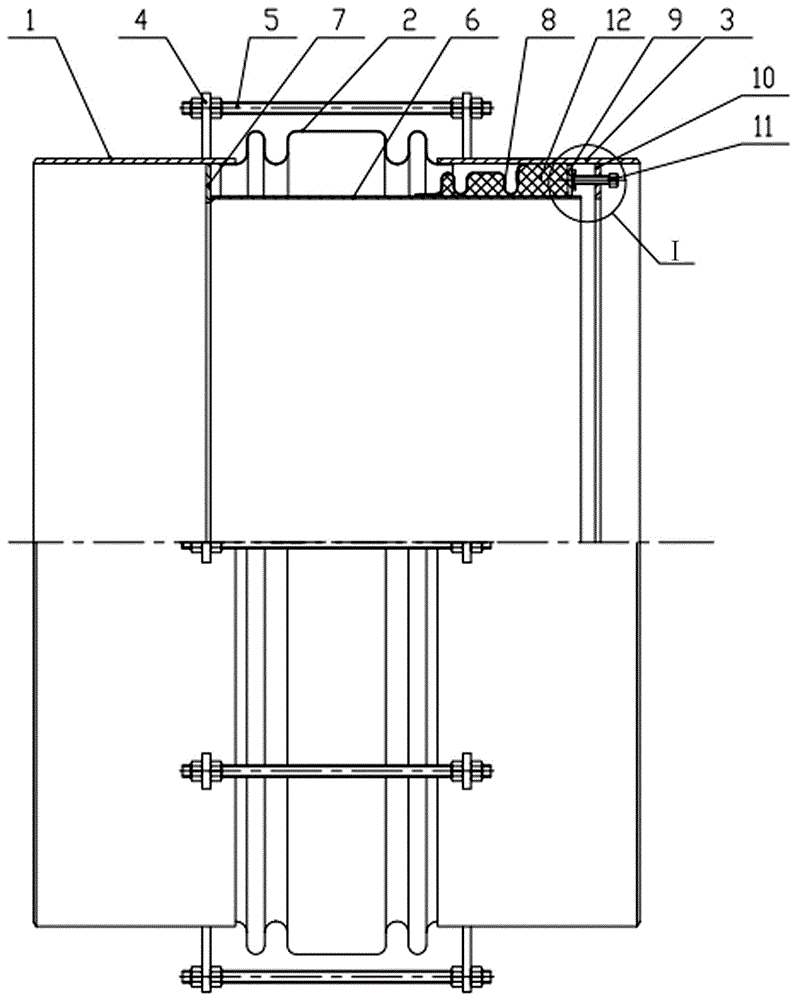

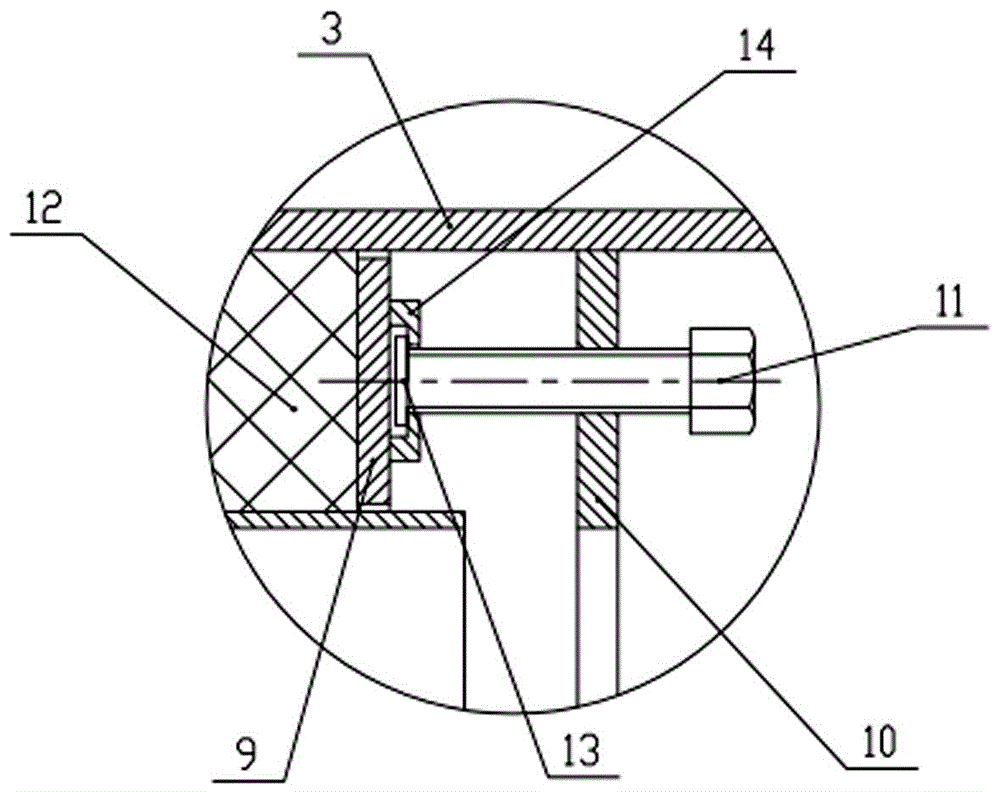

[0012] figure 1 The specific structure of the pipeline compensator used in this catalytic cracking equipment is given, which includes a front-end joint 1, a compensation bellows 2 and a rear-end joint 3 connected in sequence from front to back. The front-end joint 1 and the rear-end joint 3 have the same Inner and outer pipe diameters, the compensation bellows 2 are metal bellows. The front-end connecting pipe 1, the compensation bellows 2 and the rear-end connecting pipe 3 are respectively connected by welding. The opposite ends of the front-end connecting pipe 1 and the rear-end connecting pipe 3 are respectively welded with lugs 4 distributed along the circumference, and the two opposite lugs 4 are assembled with bolt pull rods 5, such as figure 1 In an embodiment, the two sides of each ear plate 4 are respectively equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com