Ultraviolet LED optical system for surface curing and manufacturing method thereof

A technology of an optical system and a manufacturing method, which is applied in the field of optical systems for UV LED surface curing, and can solve problems such as poor uniformity of light spots, difficulty in packaging, and difficulty in meeting the requirements of ultraviolet curing for irradiance intensity and uniformity of light spots.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0073] A method for manufacturing an ultraviolet LED surface curing optical system, comprising the following steps:

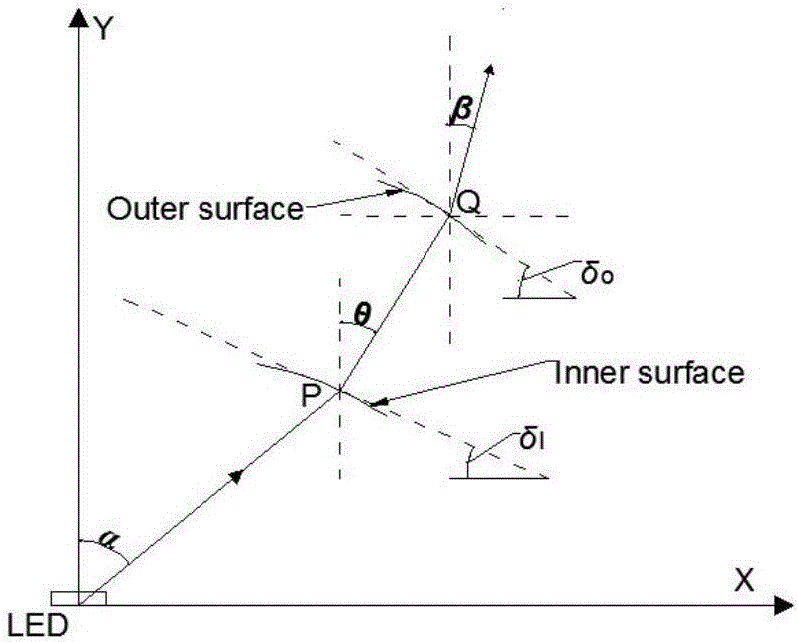

[0074] Step 1: If figure 1 As shown, a plane coordinate system is established with the coordinate origin O(0,0), including the X-axis and Y-axis, and the coordinate origin O is the ultraviolet LED light source. The following are the discrete inner and outer contours of the near-Lambertian LED lens Derivation of point coordinate iterative relationship;

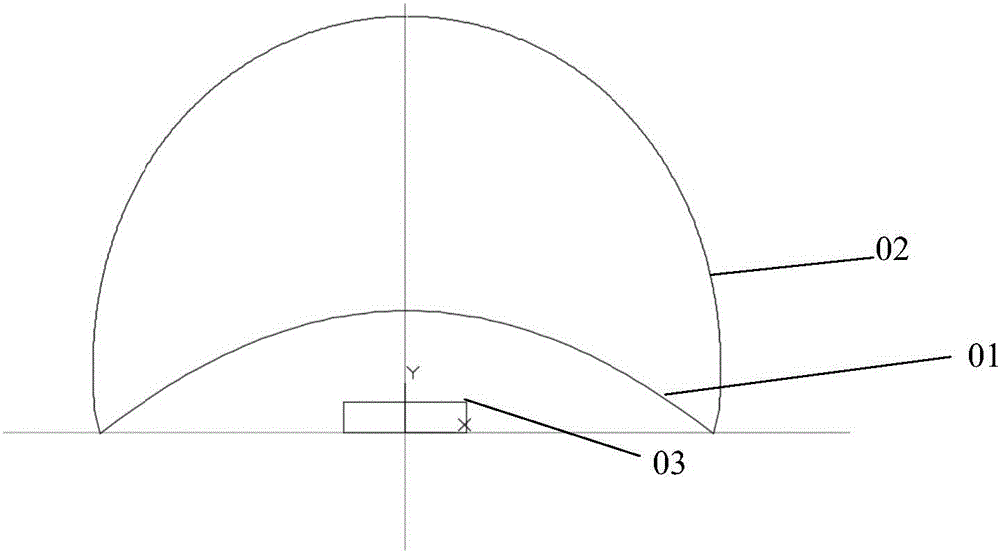

[0075] Production of near-Lambertian LED lens outline;

[0076] The light emitted from the LED chip passes through point P on the inner surface of the lens and point Q on the outer surface of the lens, and undergoes two refractions. It can be seen from the optical theory that when the two deviation angles of the light rays are equal, the phase difference of the lens is the smallest, and it can be obtained:

[0077] θ = α + β ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com