Self-calibration type measuring device and method for vertical displacement or deformation of large structure

A large-scale structure, vertical displacement technology, applied in the field of mechanical measurement, can solve the problems of increasing the complexity of the system, the error of the measurement result, affecting the measurement accuracy, etc., to achieve the effect of convenient application, improve the measurement accuracy, and overcome the displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

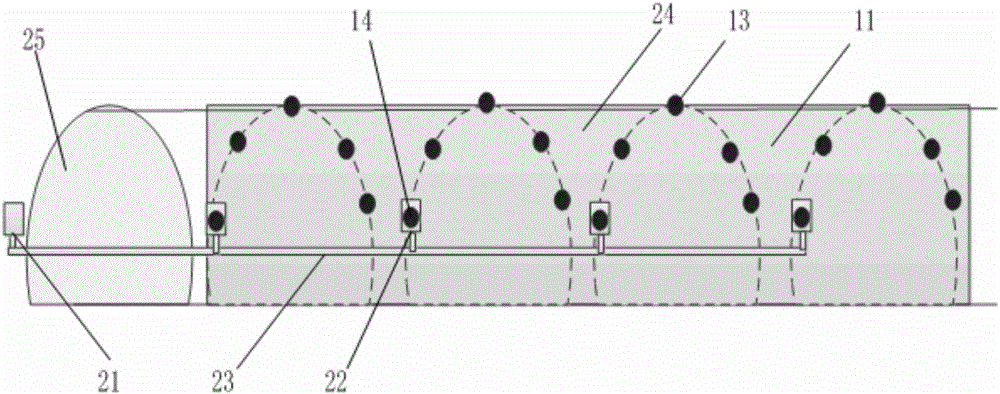

[0038] The measurement system of the present invention is mainly used for displacement or deformation measurement of certain key parts on large structures, wherein large structures include bridges, dams, tunnels, slopes and building buildings, and tunnels are taken as an example below.

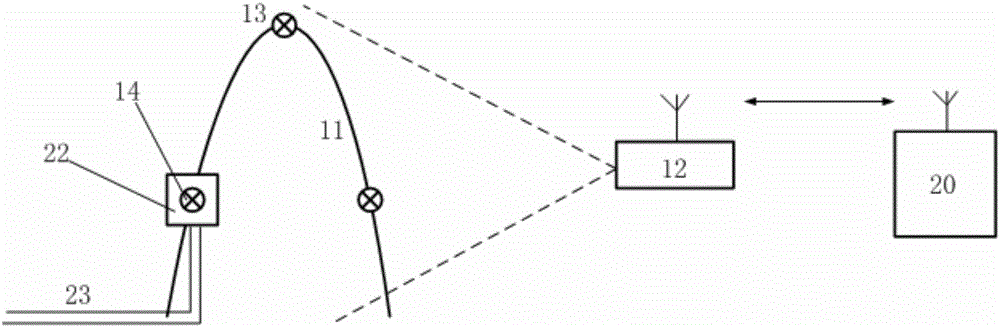

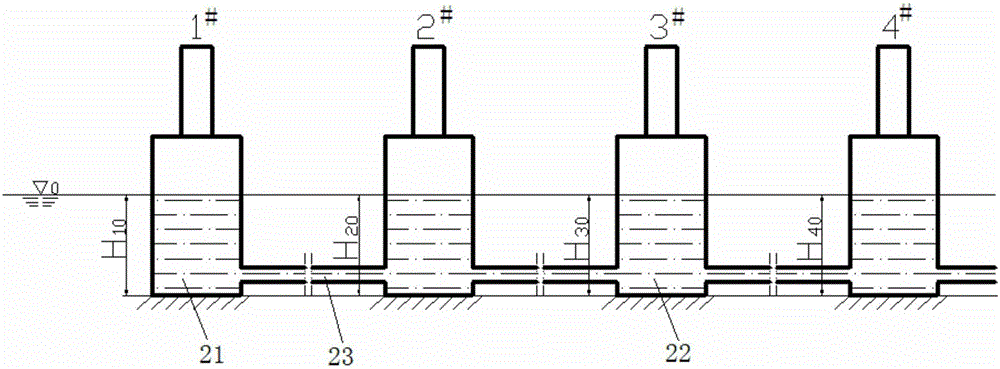

[0039] Such as figure 1 and figure 2 As shown, the self-calibrating measuring device for vertical deformation or displacement parameters of large structures includes a data processing center 20, an imaging system 12, a reference target 14, a static level and no less than one measuring target 13, the static force The level instrument includes a reference settlement probe 21 and several measuring settlement probes 22 connected by a liquid pipe 23 . The data processing center 20 is set at the far end of the measurement, the imaging system 12 is installed at a suitable position of the large structure, the measurement settlement probe 22 and the measurement target 13 are fixed on the side wall or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com