Device for measuring thickness reduction amount of plate type heat exchanger after sheet compression

A technology of plate heat exchanger and measuring device, which is applied in the field of measurement, can solve the problems of not being able to measure a whole batch of plates, labor-intensive and time-consuming plates, damage, etc., and achieve the effects of reducing measurement time, reliable quality assurance, and precise positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

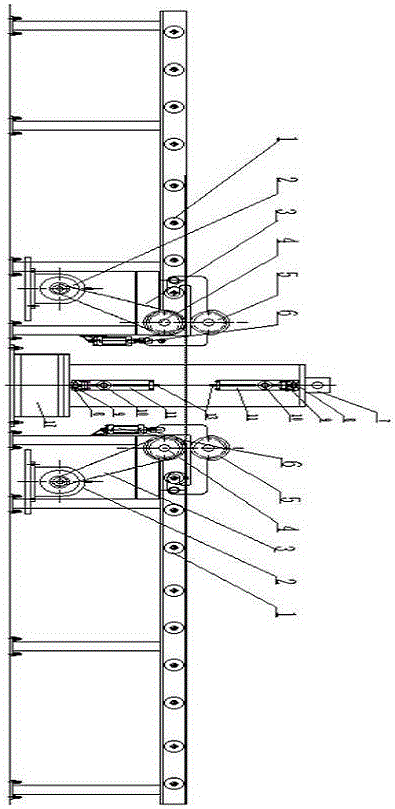

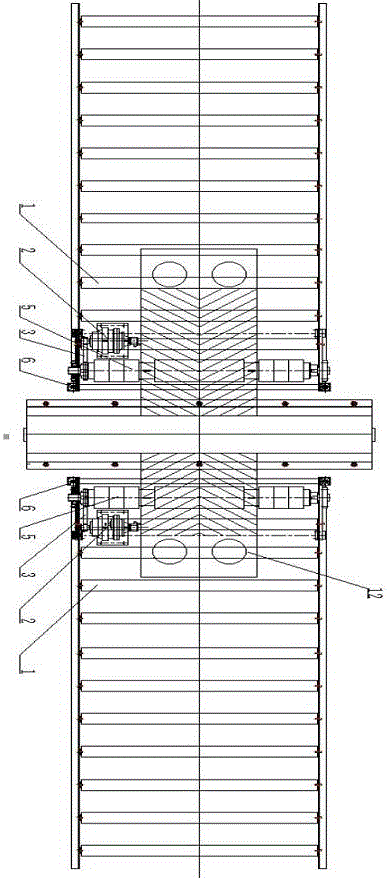

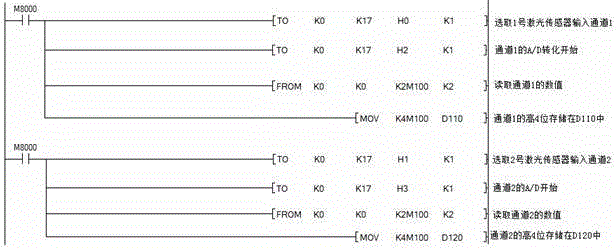

[0031] Such as figure 1 , 2 , 3, the measuring device for plate heat exchanger thinning amount after profiling proposed by the present invention includes a left transfer platform 101, a right transfer platform 102, a laser detection device 103, and a X-axis advance of the heat exchange fins. Feeding device 104; the left transfer platform 101 and the right transfer platform 102 have the same height, and the two heat exchange fin lateral feed devices 104 are respectively located at one end close to the left transfer platform 101 and the right transfer platform 102 to move the heat exchange fins from The left transfer platform 101 is transmitted to the right transfer platform 102; the laser detection device 103 is located between the left transfer platform 101 and the right transfer platform 102, and the laser detection device 103 includes two laser ranging sensors 13, which are short-distance laser sensors , one at the top and one at the bottom with the horizontal plane of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com