Experiment device and method for measuring Young modulus by beam bending method via resonance principle

A technology of Young's modulus and experimental device, which is applied in teaching models, educational appliances, and analysis of solids using sonic/ultrasonic/infrasonic waves, etc., can solve the problems affecting the accuracy of experimental results, single principle, and difficult to understand.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

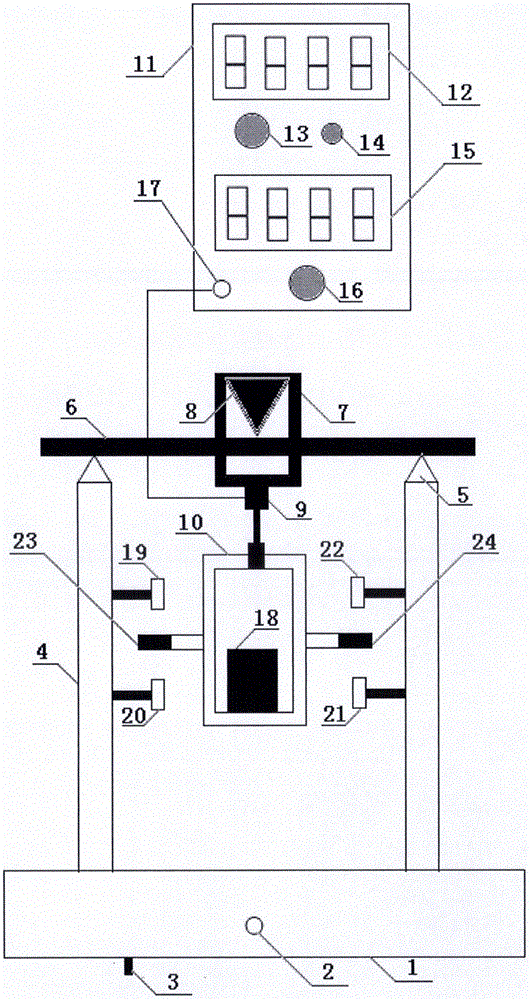

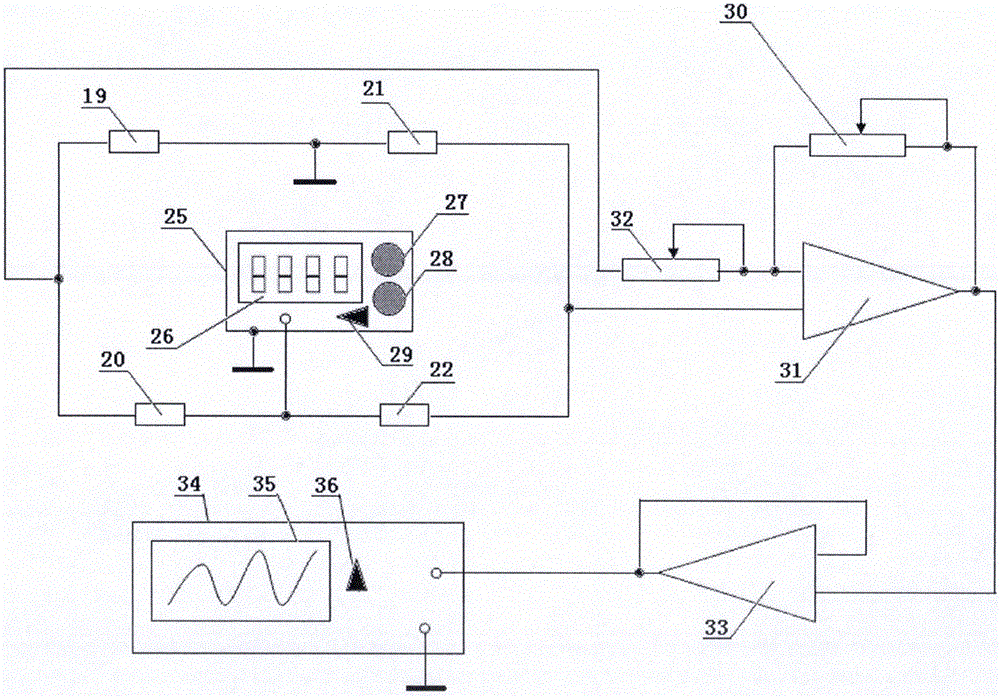

[0040] Among the figure, two columns 4 are set on the base 1, and a steel knife edge is respectively fixed at the upper ends of the two columns 4, i.e. the column knife edge 5, the blades of the two knife edges are parallel to each other, and the two ends of a rectangular cross-section metal beam 6 freely straddle the Placed on the edge of the upper ends of the two columns 4, a copper frame 7 is placed on the rectangular cross-section metal beam 6, and the contact between the copper frame 7 and the rectangular cross-section metal beam 6 is also a knife edge, that is, the copper frame knife edge 8, and the copper frame knife edge 8 Just in the middle of the upper ends of the two columns, a vibrator 9 is provided at the lower end of the copper frame 7. The vibrator 9 is connected to a metal frame 10 through a connecting device, and an iron block 18 is fixed inside the metal frame 10. The exciter 9 is connected to the sinusoidal signal source 11 through the interface 17 between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com