Advanced oxidation treatment experimental platform for wastewater

An experimental platform, advanced oxidation technology, applied in oxidation water/sewage treatment, light water/sewage treatment, etc., can solve the problems that affect students' understanding of the course, poor students' active participation, and poor course synchronization, and achieve a compact structure. , Small footprint, easy to move

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below with reference to the accompanying drawings and examples. The present invention is not limited to this embodiment. Any design that adopts the design structure and ideas of the present invention and makes some simple changes or modifications will fall into the protection of the present invention. Range.

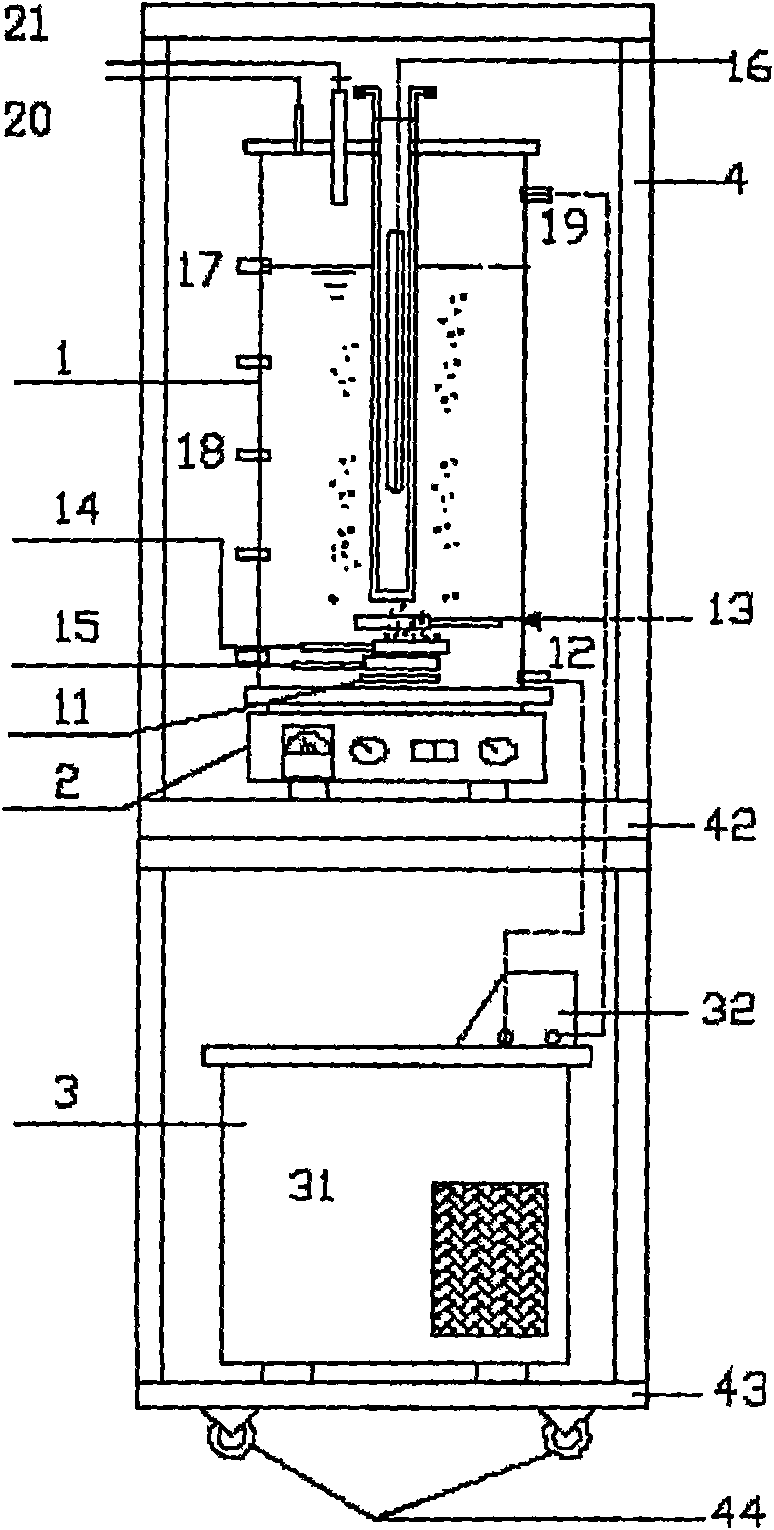

[0016] Such as figure 1 As shown, the experimental platform for advanced oxidation treatment of wastewater of the present invention includes a reaction water tank 1, a stirring device 2, a constant temperature water tank 3, and a support 4. The stirring device 2 is an electromagnetic stirrer or a microwave generator.

[0017] An upper shelf 42 and a lower shelf 43 are installed on the bracket 4, and a universal wheel 44 can be installed at the bottom of the bracket. The reaction water tank 1 and the stirring device 2 are placed on the upper shelf 42 of the support 4, and the thermostatic water tank 3 is placed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com