A dehumidification and impurity removal system for gas analyzers under slightly positive and slightly negative pressure conditions

A gas analyzer, slightly positive and slightly negative pressure technology, applied in the direction of analyzing materials, instruments, scientific instruments, etc., can solve the problem of unable to take samples, etc., and achieve the effect of protection safety, unique process and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention can be explained in more detail by the following examples, the present invention is not limited to the following examples, the purpose of disclosing the present invention is intended to protect all changes and improvements within the scope of the present invention;

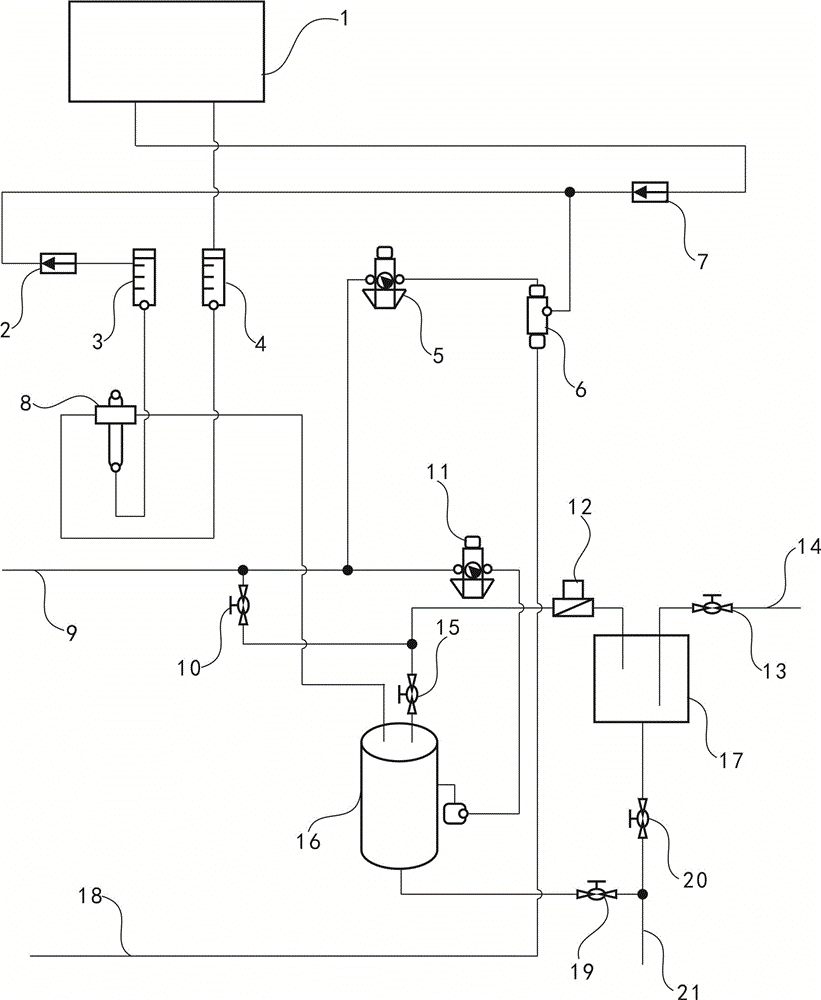

[0013] combined with figure 1 The gas analyzer dehumidification and impurity removal system under slightly positive and slightly negative pressure conditions includes a gas analyzer 1, a rotameter A3, a rotameter B4, an air decompression filter A5, a jet pump 6, a filter A8, Instrument air inlet 9, air decompression filter B11, filter B12, gas medium inlet 14, spin cooler 16, water removal tank 17, gas medium outlet 18 and waste liquid port 21, the gas medium inlet 14 One end is connected to the inlet of the water removal tank 17, the outlet of the water removal tank 17 is connected to the inlet of the filter B12, and the outlet of the filter B12 is connected to the inlet of the spin c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com