Substrate temperature monitoring device, dry etching equipment and substrate temperature monitoring method

A monitoring device and substrate technology, which is applied in semiconductor/solid-state device testing/measurement, electrical components, semiconductor/solid-state device manufacturing, etc., can solve the problems of general thermal conductivity, waste of production cost, roughness and inequality, and avoid the Mla phenomenon Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] like Figure 4 As shown, this embodiment provides a substrate temperature monitoring device 3, the substrate temperature monitoring device 3 includes a temperature sensing module 31 and a difference calculation module 32, wherein the temperature sensing module 31 is installed in the etching process of the etching equipment Inside the chamber, it is used to sense the temperature of each area on the substrate in the etching chamber in real time during etching; the difference calculation module 32 is used to calculate the temperature on the substrate according to the temperature of each area on the substrate sensed by the temperature sensing module 31. The temperature difference between each contact area and its surrounding non-contact area.

[0056] It should be noted that the "contact area" mentioned in this embodiment refers to the area on the substrate corresponding to the lower electrode in the etching chamber during etching, that is, the area on the substrate that is...

Embodiment 2

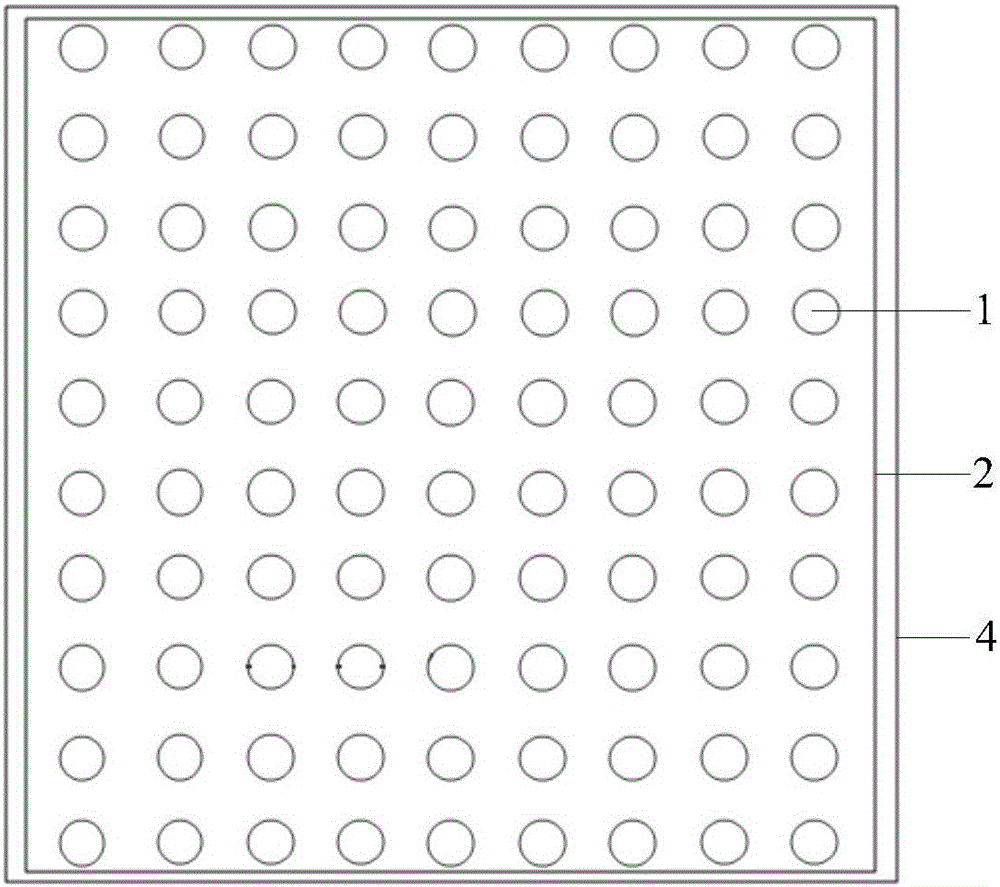

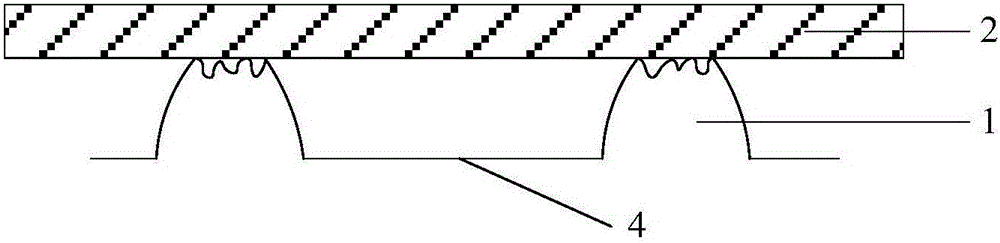

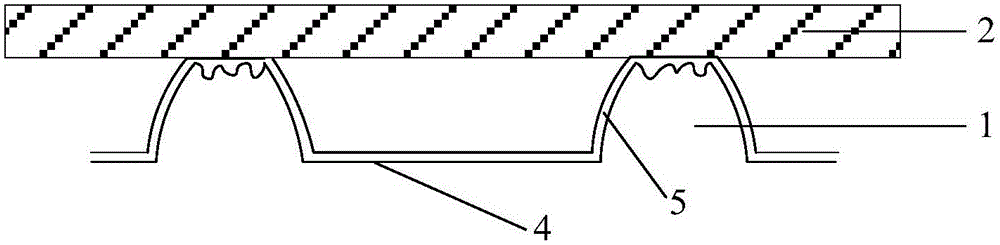

[0077] Based on Embodiment 1, this embodiment provides a dry etching equipment, such as Figure 15 As shown, the dry etching equipment includes: an etching chamber 6, a base 4 disposed below the interior of the etching chamber 6, a plurality of lower electrodes 1 disposed on the base 4, disposed above the etching chamber 6 The upper electrode 7, and the substrate temperature monitoring device as described in the first embodiment.

[0078] exist Figure 15 Only some components in the substrate temperature monitoring device are exemplarily shown in the figure: a plurality of infrared temperature sensors 311 installed on the upper part of the inner wall of the etching chamber 6, and a heating device 36 arranged inside each lower electrode 1, wherein The infrared temperature sensor 311 is used to sense the temperature of each area on the substrate 2 in real time during etching, and the heating device 36 is used to perform temperature compensation on the contact area on the substr...

Embodiment 3

[0081] This embodiment provides a substrate temperature monitoring method, the substrate temperature monitoring method includes the following steps:

[0082] Real-time sensing the temperature of each area on the substrate in the etching chamber during etching;

[0083] calculating the temperature difference between each contact area on the substrate and its surrounding non-contact area according to the sensed temperature of each area on the substrate;

[0084] Wherein, the contact area is an area on the substrate corresponding to the lower electrode in the etching chamber during etching, and the non-contact area is an area on the substrate not corresponding to the lower electrode during etching.

[0085] The beneficial effects of the substrate temperature monitoring method provided in this embodiment are the same as those of the substrate temperature monitoring device provided in Embodiment 1, and will not be repeated here.

[0086] As a preferred option, such as Figure 16 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com