Method and system for testing bonding degree at any position on wafer product

A technology of any position and test method, applied in semiconductor/solid-state device test/measurement, electrical components, circuits, etc., can solve the problem of inability to evaluate the degree of bonding, and achieve the effect of simple test method, reduced efficiency and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

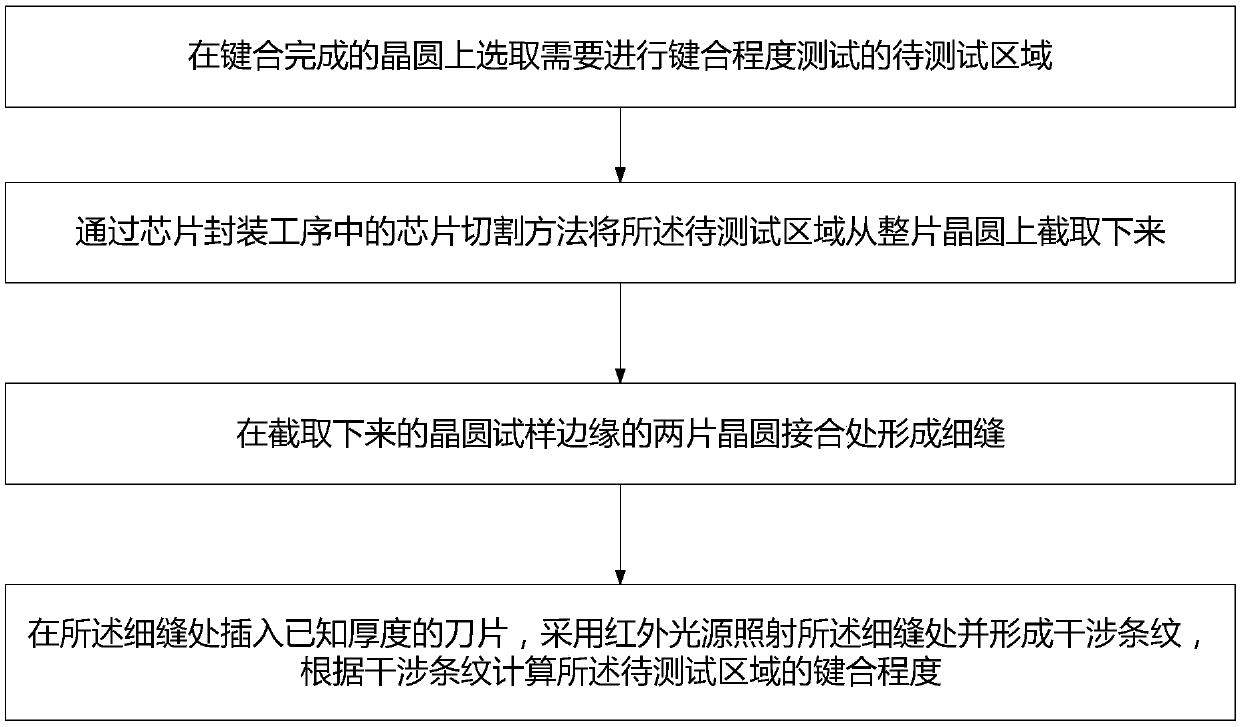

[0039] figure 1 It is a schematic flow chart of a method for testing the degree of bonding at any position on a wafer product in Embodiment 1, comprising the following steps:

[0040] Step 1. Select the area to be tested on the bonded wafer that needs to be tested for the degree of bonding. The area to be tested can be located at any position on the wafer, such as the edge of the wafer, the center of the wafer, or an area close to the center of the wafer.

[0041] In step 2, the area to be tested is cut off from the entire wafer by a chip cutting method in the chip packaging process. In this embodiment, the region to be tested is cut off from the entire wafer by using a laser method. In other embodiments, a saw bla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com