Quick dismounting and filling-sealing apparatus for electric connector

An electrical connector and potting technology, which is applied in the field of quick disassembly and potting devices for electrical connectors, can solve the problems of large assembly gap and inconvenient disassembly and assembly, and achieve the effects of high docking accuracy, reliable use and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

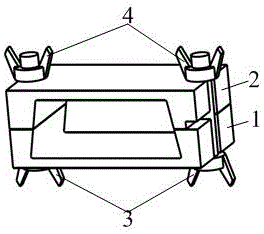

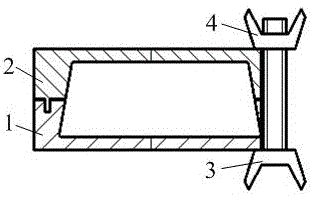

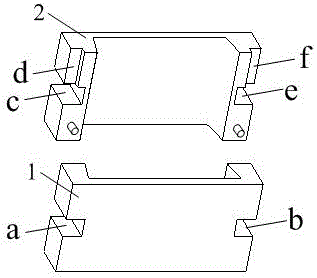

[0013] A quick disassembly, assembly and sealing device for an electrical connector, comprising: an aluminum processed part A1 and an aluminum processed part B2. Also includes: wing bolt 3 and wing nut 4.

[0014] The aluminum processing part A1 is a U-shaped machining part, and there are two blind holes on the joint surface, with a groove a on one side and a groove b on the other side. The aluminum processing part B2 is also a U-shaped machining part. There are two cylindrical pins on the joining surface, groove c and groove d on one side, and groove e and groove f on the other side.

[0015] The aluminum processing part A1 is connected with the aluminum processing part B2 through cylindrical pins, the butterfly bolt 3 is inserted along the groove a and groove c on both sides, the wing nut 4 is inserted along the groove b and groove e, and the aluminum The machined part A1 and the aluminum machined part B2 are fastened.

[0016] When working, put the tail cable of the elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com