Support conveyor

A technology for conveyors and shells, applied in the field of stent conveyors and conveyors, which can solve problems such as large pushing force, structural limitations of the conveying system, and inconvenient surgical operations for medical staff, so as to ensure safe operation and avoid tremors and offsets. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The following definitions of directions are all defined according to the directions observed by the user when holding the stent transporter.

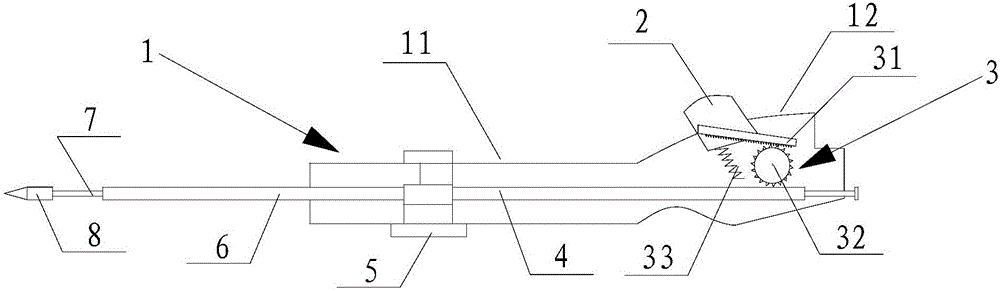

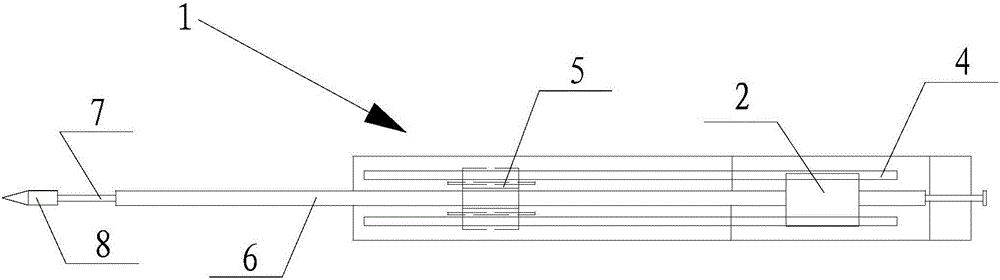

[0020] Such as figure 1 and figure 2 The shown stent delivery device mainly includes a housing 1, a trigger 2, a transmission mechanism 3, an outer sheath 6, a central catheter 7, and the like.

[0021] Wherein, the casing 1 includes a straight pipe portion 11 and a handle portion 12, which can be set as one or detachable according to needs; in addition, the casing 1 can be set to be composed of two symmetrical parts, and the actual user can put the They are disassembled to replace damaged parts. The trigger 2 is installed on the housing 1, and only needs to be pressed when using the support conveyor. Part of the central conduit 7 is located in the housing 1 , its rear end is fixed or mounted on the housing 1 (it can also extend out of the housing 1 ), and its front end extends out of the housing 1 . The outer sheath 6 is sl...

Embodiment 3

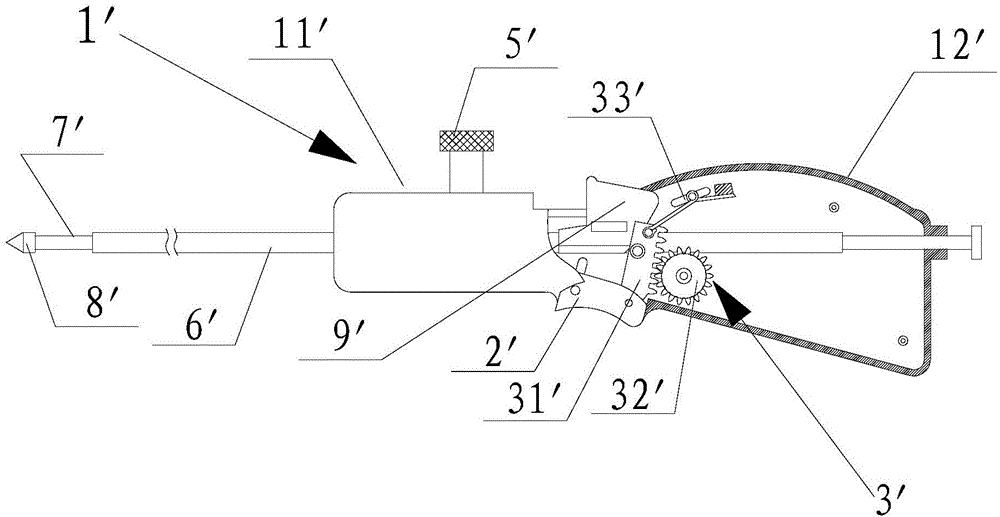

[0024] Such as image 3 The structure of the shown stent delivery device is similar to that of the delivery device in Embodiment 1, and also includes components such as a housing 1', a trigger 2', a transmission mechanism 3', an outer sheath tube 6', and a central catheter 7'.

[0025] The housing 1' includes a straight pipe part 11' and a handle part 12', which can be set as one or detachable as required; in addition, the housing 1' can be set to be composed of two symmetrical parts. They can be disassembled to replace damaged parts. The trigger 2' is installed on the housing 1', and only needs to be pressed when using the support conveyor. The part of the central conduit 7' is located in the casing 1', its rear end is fixed or installed on the casing 1' (it can also extend outside the casing 1'), and its front end extends outside the casing 1' ( This end is fitted with a tip 8' located outside the outer sheath 6'). The outer sheath tube 6' is slidably sleeved on the centr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com