Control method used for discharge opening of cone crusher with multiple hydraulic cylinders

A technology of cone crusher and discharge port, which is applied in the direction of grain processing, etc., to achieve the effect of simple and convenient installation and debugging, accurate reading of values, and accurate data support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

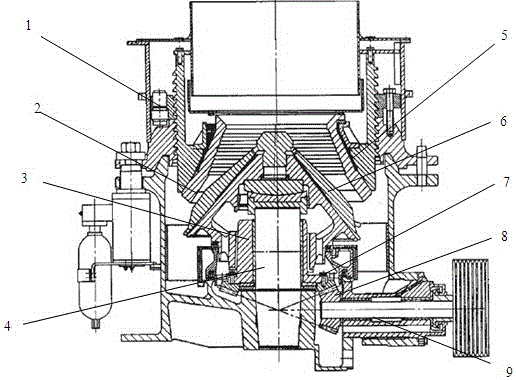

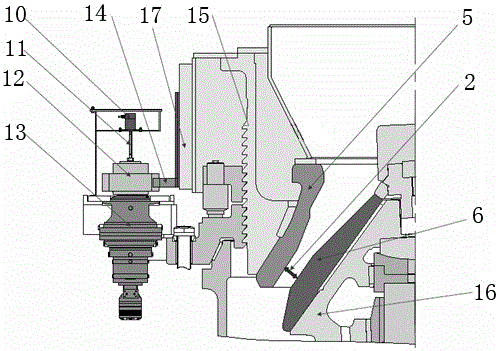

[0030] A method for controlling the discharge opening of a multi-hydraulic-cylinder cone crusher, the implementation steps of which are as follows:

[0031] 1. Analyze the control object, combine the working principle of multi-hydraulic cylinder cone crushing and the measurement principle of the discharge port, and propose a control plan.

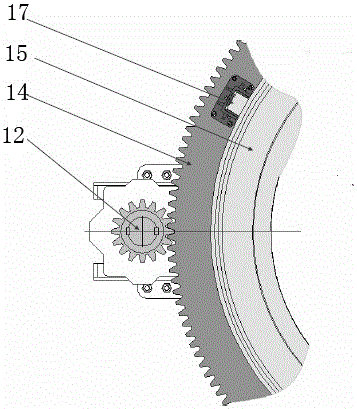

[0032] 2. The implementation of the plan, using the multi-turn absolute encoder to detect the number of rotating teeth of the drive pinion, recording the position information of the fixed cone, using PLC for data calculation and logic control, and converting the size of the discharge port by measuring the pitch value.

[0033] 3. Program implementation, completed in three steps

[0034] (1) Read the output value of the encoder and convert the Gray code into a double integer value.

[0035] (2) New liner calibration: When the cone crusher is replaced with a new liner, this position is calibrated as the absolute zero point of the new liner, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com