Glue application gun and glue application method of compartment covers

A cover glue gun and engine room cover technology, which is applied in the direction of spraying devices, spraying devices, liquid spraying devices, etc., can solve the problems of manual glue coating and sealing, tapes that cannot be reused, and widths that are not uniform, etc., to achieve glue coating Simple work, time-saving and labor-saving operation, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

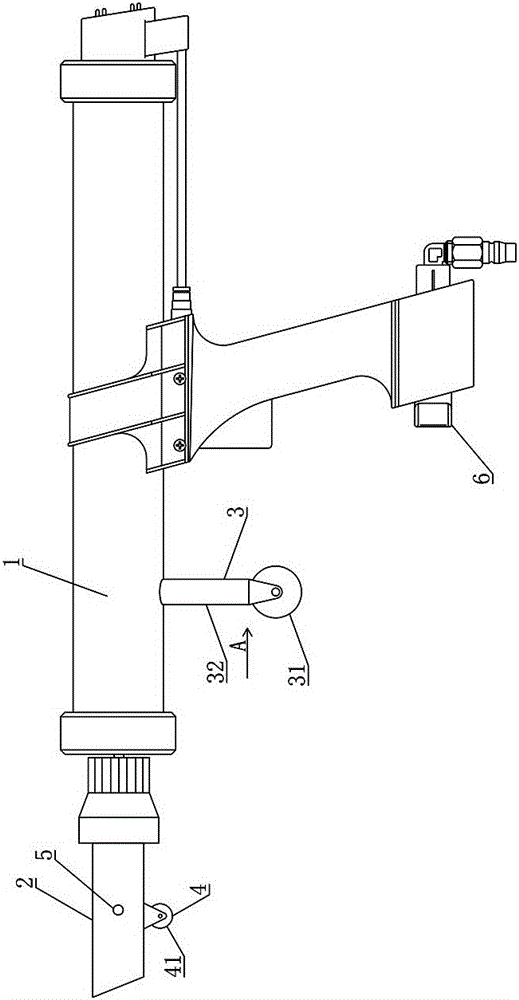

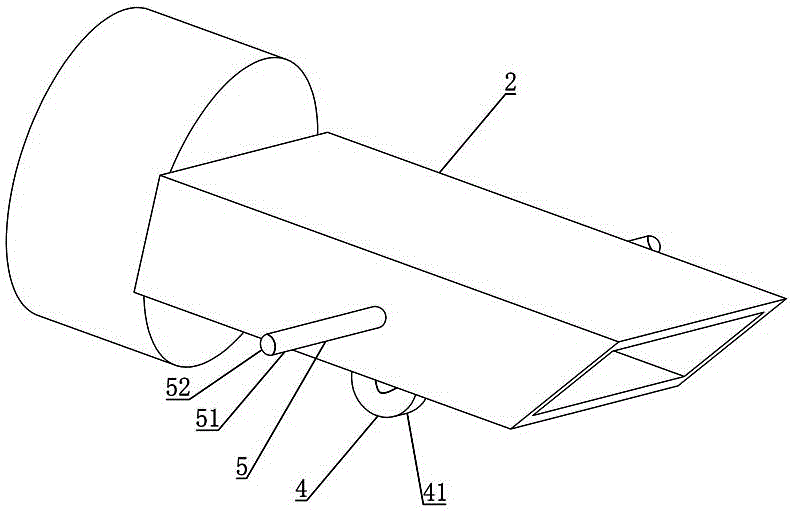

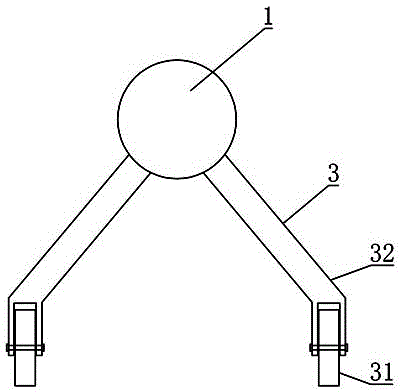

[0027] Such as Figure 1 to Figure 3 As shown, the nacelle cover gluing gun of the present embodiment includes a gun body 1, the front portion of the gun body 1 is provided with a sliding assembly 3 that can slide along the surface of the nacelle cover, and the front end of the gun body 1 is detachably connected with a nozzle 2, Below the gun nozzle 2 is provided with a guide assembly 4 for clamping in the butt joint grooves of the two nacelle covers for guidance. During the gluing operation, the guide assembly 4 is placed in the docking groove, which can ensure that the gun body 1 moves directly along the docking groove between the two cabin covers during the gluing process, ensuring the linearity of the rubber strip; While moving, the sliding assembly 3 supports the gun body 1 and runs along the surface of the nacelle cover, which can ensure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com