Automatic groove cleaning machine for motor stator inner groove

A motor stator, automatic cleaning technology, applied in the direction of electric components, manufacturing motor generators, manufacturing stator/rotor body, etc., can solve the problems of harmful dust harmful to health, unstable quality, high labor intensity, etc., to achieve easy installation and adjustment, Small size, high cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

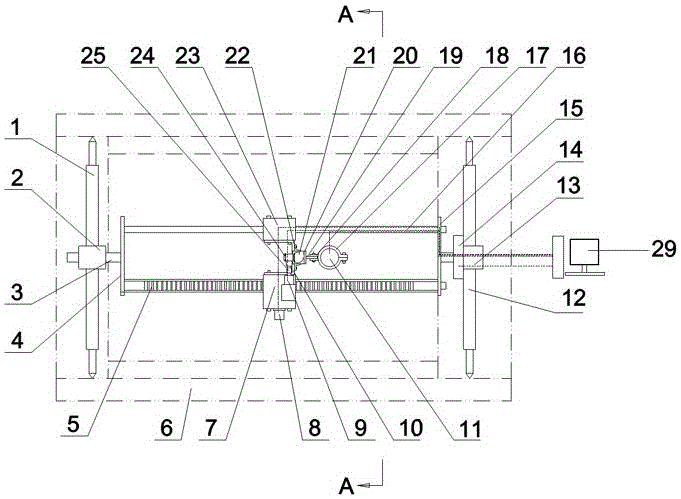

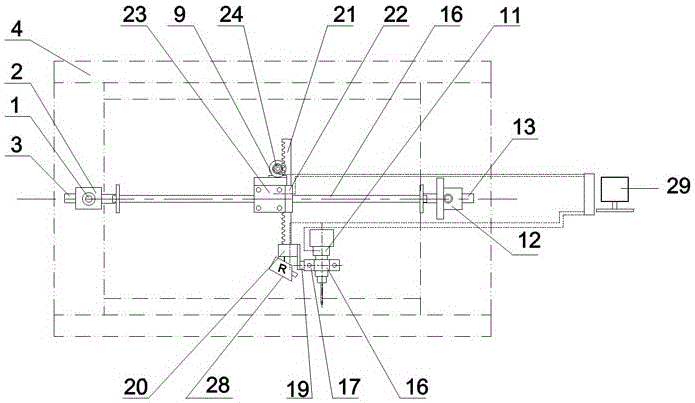

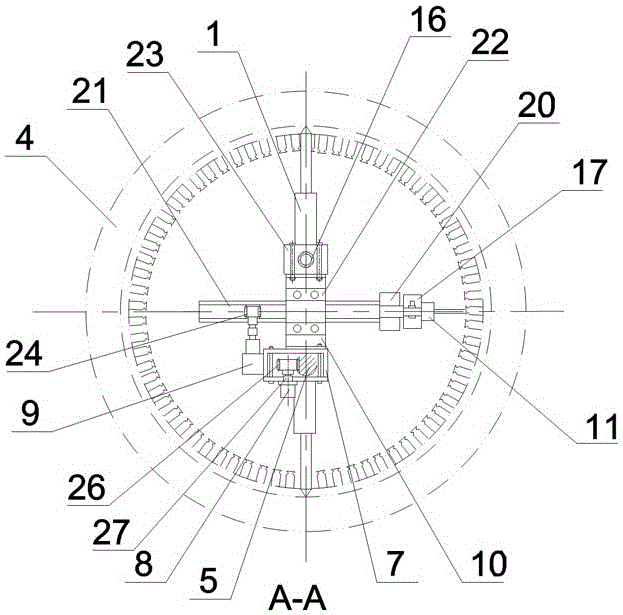

[0022] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

[0023] Such as figure 1 , 2, and 3, the automatic slot cleaning machine for the inner groove of the motor stator of the present invention consists of a bidirectional left pneumatic strut 1 and a bidirectional right pneumatic strut 12 arranged in the inner groove of the motor stator 6, and the two ends are respectively connected with the bidirectional The left pneumatic strut 1 and the two-way right pneumatic strut 12 are connected to the slewing bracket, the longitudinal moving device set on the slewing bracket, the radial moving device set on the longitudinal moving device, set on the radial moving device The slot-clearing electric drill 11 and the electric control device 29 are formed. After starting the two-way left pneumatic strut 1 and the two-way right pneumatic strut 12, the whole rotary bracket is fixed in the inner groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com