Discharge device of glass tube cleaning machine

A discharge device and glass tube technology, applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of water not being scraped clean, glass tube damage, etc., to achieve better working conditions and stable quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

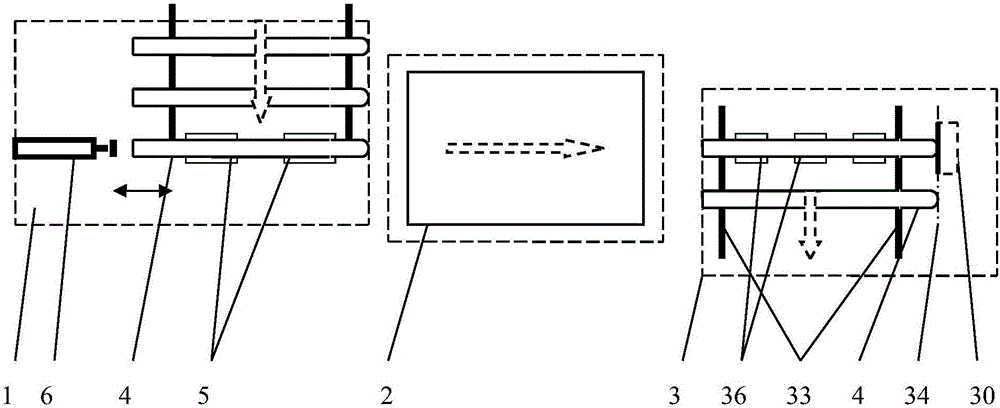

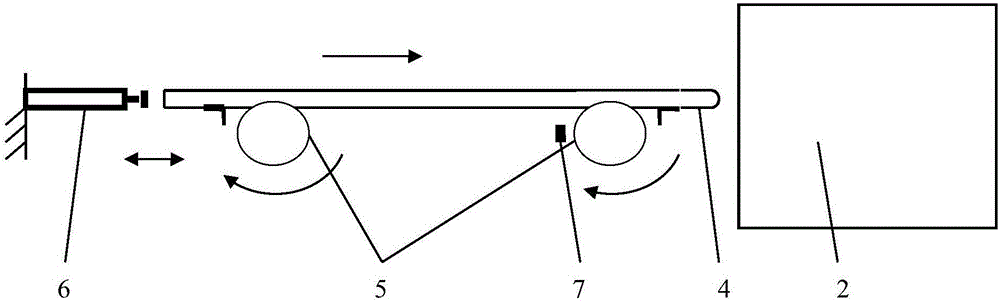

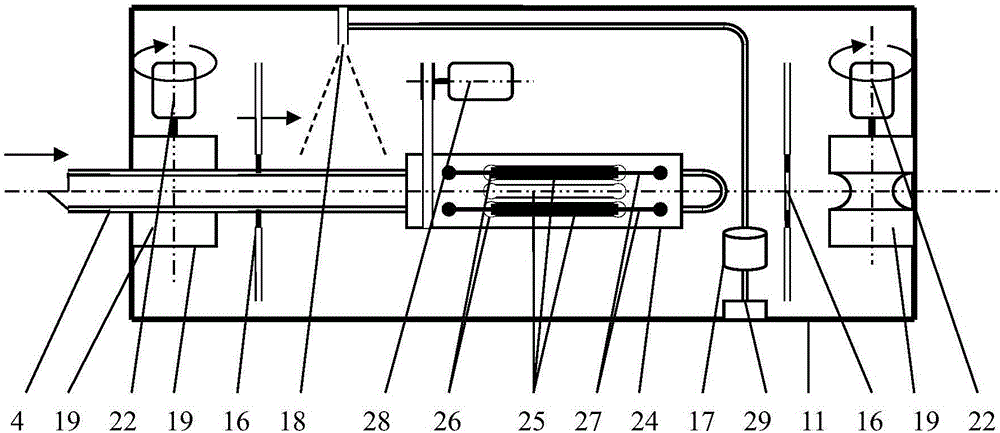

[0015] Example 1, the glass tube automatic cleaning equipment with an electric cleaning cylinder includes a feeding mechanism 1, a cleaning device 2 and a discharging device 3; the feeding mechanism 1, the cleaning device 2 and the discharging device 3 move according to the movement of the cleaned glass tube. The paths are laid out sequentially.

[0016] The feeding mechanism 1 includes two feeding rollers 5, a pneumatic feeding propeller 6 and a feeding sensor 7 arranged one after the other along the moving direction of the glass tube 4; Matching semicircular concave surface; the glass tube 4 enters the feed roller 5, and the feed sensor 7 outputs a signal to make the pneumatic feed pusher 6 complete a push / reset action.

[0017] The cleaning device 2 includes a spray tank body 11, two sets of rubber wheel driving mechanisms 12 and 13 arranged along the axis of the cleaning device 2, an electric cleaning cylinder 14, and a wiper located between the two sets of rubber wheel dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com