Grinding wheel dresser for numerical control grinder

A technology of grinding wheel dresser and CNC grinding machine, which is applied to the parts of grinding machine tools, grinding/polishing equipment, parts of boring machine/drilling machine, etc. Problems such as processing accuracy and low production efficiency can achieve the effect of low requirements for operators, improved trimming accuracy, and simple operation methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation, structure, features and effects provided by the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

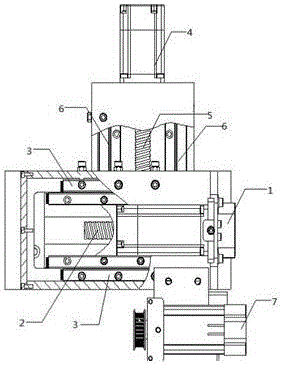

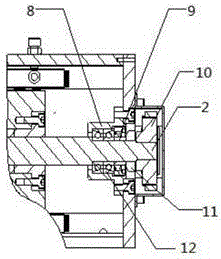

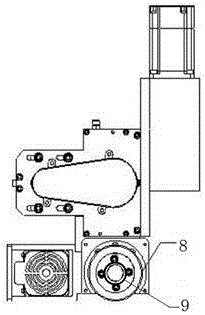

[0018] Such as figure 1 The shown a kind of numerical control grinder grinding wheel dresser, comprises dressing wheel rotation mechanism and dressing wheel feeding mechanism, and described dressing wheel rotation mechanism comprises dressing wheel rotating motor, and diamond dressing wheel 8 driven by said dressing wheel rotating motor 7 , the diamond dressing wheel includes a dressing wheel main shaft, a flange disposed on the dressing wheel main shaft, and a dynamic balance regulator 9 arranged on the flange; the dressing wheel feeding mechanism is divided into a dressing wheel main shaft feeding part and a dressing Wheel vertical feed section.

[0019] The main shaft feeding part of the dressing wheel includes a main shaft feeding servo motor 1, and the main shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com