Inner tube automatic splicing system

An automatic splicing and inner tube technology, which is applied to tubular items, household appliances, other household appliances, etc., can solve the problems of many uncontrollable factors, increased labor costs, and high scrap rate, so as to avoid a large number of uncontrollable factors and achieve consistent improvement. performance and quality, the effect of reducing the footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to make the object, technical solution and advantages of the present invention clearer, various embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

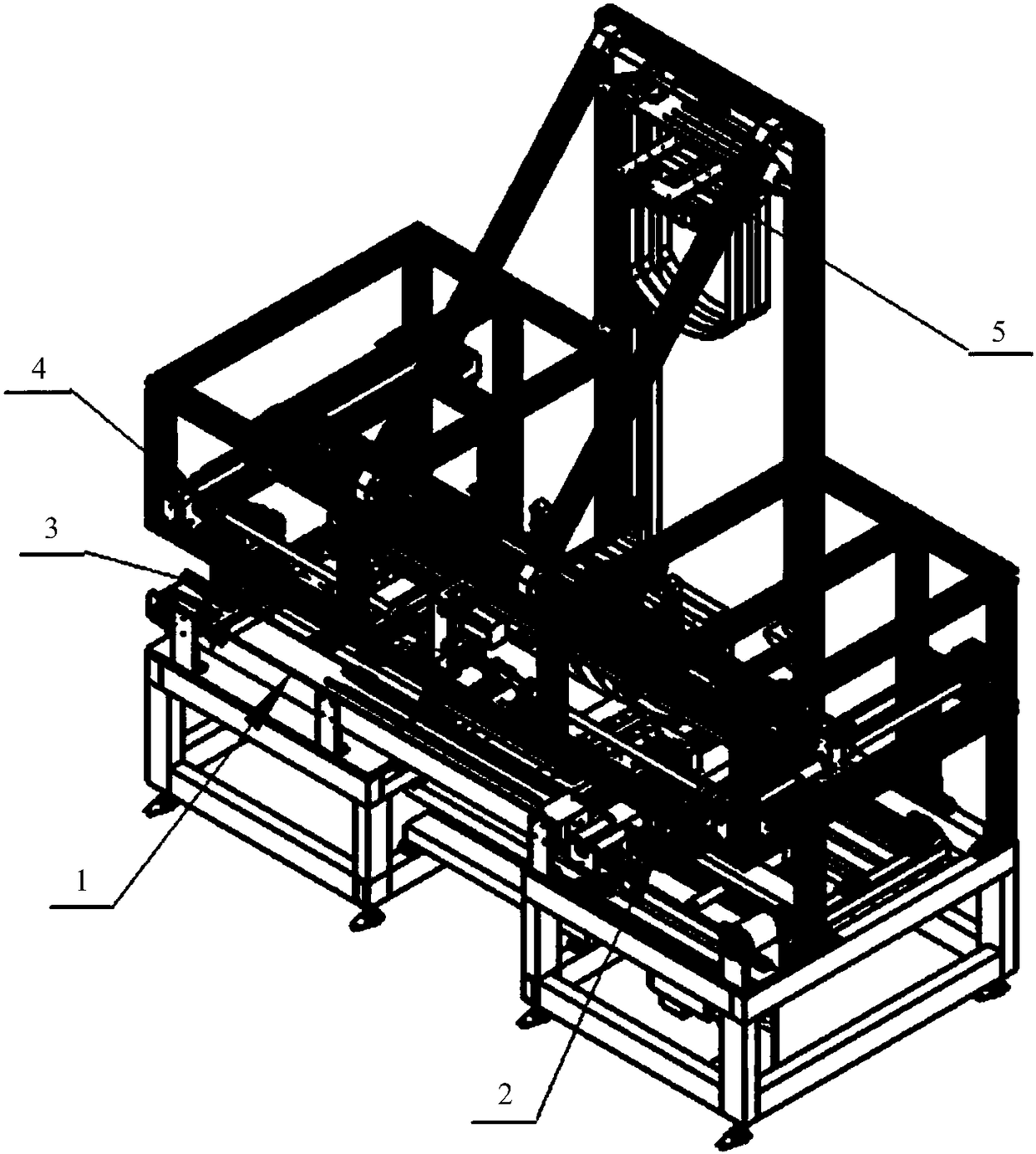

[0047] Please refer to Figure 1 to Figure 8 , an inner tube automatic splicing system, comprising:

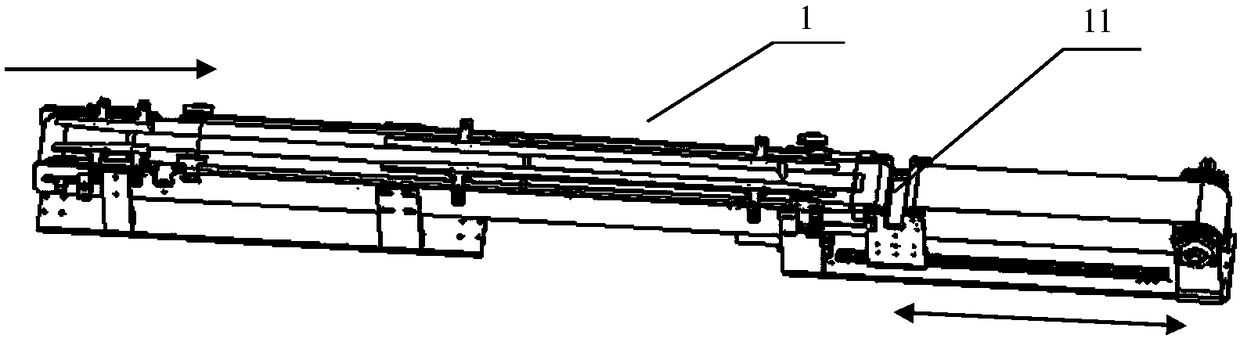

[0048] Incoming conveyor line 1 (see figure 2 ), for delivering the unspliced inner tube to the first position;

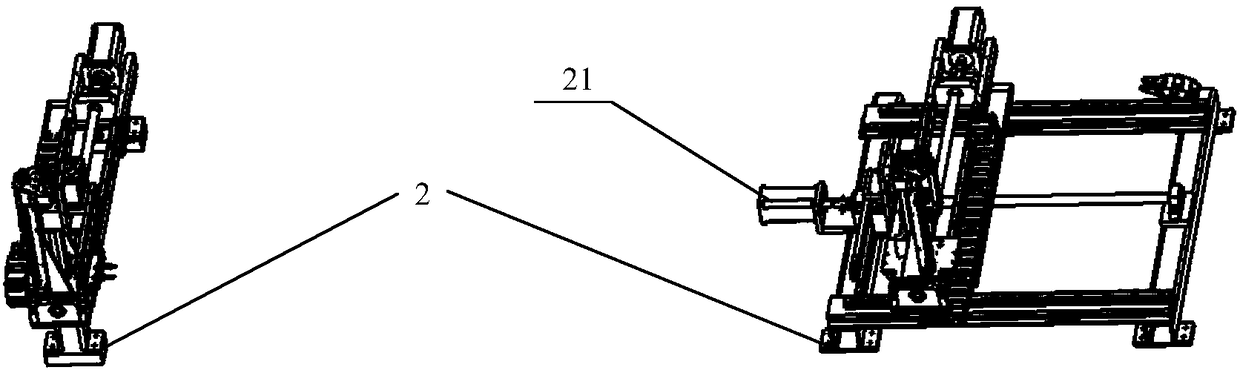

[0049] Reclaiming mechanism 2 (see image 3 ) for clamping the unspliced inner tube from said first position to a second position;

[0050] Feeding turning mechanism 4 (see Figure 4 ), for:

[0051] transporting an unspliced innertube from said second location to a third location;

[0052] Flip the ends of the unspliced inner tube so that the ends face each other;

[0053] Move the two ends of the unspliced inner tube so that they are in zero-distance contact;

[0054] The splicing machine is used to splice the two en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com