Washing machine with infrared switch and dewatering control method for same

A washing machine and infrared technology, applied in the control device of washing machine, washing machine with container, other washing machines, etc., can solve the problems of time-consuming, large cumulative error, electricity consumption, etc., saving design workload, improving design efficiency, and small error Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

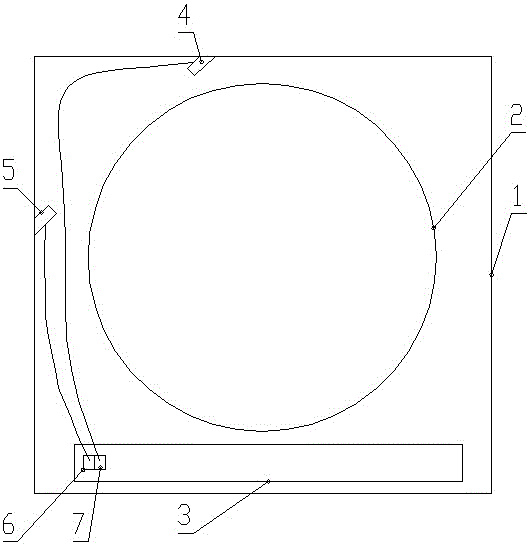

[0029] Such as figure 1 As shown, the washing machine provided with an infrared safety switch of the present invention includes a rectangular box body 1, and the box body 1 is provided with an inner and outer barrel combination 2 (that is, a combined structure of an inner barrel and an outer barrel), and the outer side wall of the inner and outer barrel combination 2 and the box body 1 There is a gap between the inner walls; there is a program controller 3 inside the cabinet 1, and an infrared safety switch is provided on the inner wall of the cabinet 1. The infrared safety switch includes an infrared emitting unit 4 and an infrared receiving unit 5, and the program controller 3 is provided with two The connecting terminals are respectively the transmitting unit connecting terminal 7 and the receiving unit connecting terminal 6;

[0030] The infrared emitting unit 4 is connected to the transmitting unit terminal 7 through the first wire, and the infrared receiving unit 5 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com